Organization of service in public catering Radchenko. Radchenko L.A. Organization of production at catering establishments. Questions for knowledge control

Year of issue: 2011

Genre: Economy

Publisher: Trinity bridge

Format: PDF

Quality: OCR

Number of pages: 232

Description: In the textbook "Organization of production at enterprises Catering» various types of catering establishments are considered, as a set of workshops and production sites included in it, premises for servicing consumers and various kinds of administrative and economic services, activities are studied individual divisions and their relationship in terms of effective use resources of each of them and the enterprise as a whole. In addition, issues of specialization of production, division and cooperation of labor within the enterprise, methods for establishing modern progressive technical standards, etc. are considered in detail. catering products, food hygiene, catering equipment, sanitation and hygiene, etc.

The textbook corresponds to the program of the course "Organization of production and service at a public catering enterprise" and consists of nine sections, the study of which will allow students to acquire the necessary knowledge and practical skills in organizing production activities public catering enterprises, providing an increase in the stability of its work, competitiveness and a significant improvement in the quality of products.

The textbook is intended for students of technological and trade and economic universities, and may also be of interest to practitioners studying in the system of retraining and advanced training. Textbook content

"Organization of production at public catering enterprises"

CLASSIFICATION OF PUBLIC CATERING ENTERPRISES

- Features of production and trade activities of public catering enterprises in a market economy

- Catering services and requirements for them

- The main types of catering establishments

- Harvesting enterprises: types, features of activity

- Canteen

- Restaurant

- Cafe. Features of the organization of the cafeteria

- Quick Service Establishments (FSPs)

- Peculiarities retail in catering

- Role wholesale trade in the supply chain

- Commodity supply of catering establishments

- Purpose of storage facilities

- Warehouse composition

- Space-planning and sanitary-hygienic requirements for warehouses

- Organization of warehouse operations

- Purpose and classification of containers

- Organization of packaging and measures to reduce packaging costs

- Operational planning of the work of the production of blank enterprises

- Operational planning at enterprises with a full production cycle

- Menu types, their characteristics

- Calculation of raw materials and preparation of tasks for teams of cooks. Operational control of production work

- Technological documents for catering products

- Collections of recipes for dishes and culinary products

- Technological cards

- Technical and technological map

- industry standards, specifications and technological instructions for semi-finished products and culinary products

- Production infrastructure

- The relationship of production shops with other groups of premises

- Creation of optimal working conditions

- Job organization requirements

- Production of semi-finished products in the vegetable shop of a procurement enterprise

- Organization of the work of the vegetable shop at enterprises with a full production cycle

- Production of semi-finished products in the meat shop of a procurement enterprise

- Production of semi-finished products in the fish shop of a procurement enterprise

- Organization of the work of the poultry and offal processing workshop

- Organization of the work of the meat and fish shop

- Organization of the work of workshops for the finalization of semi-finished products, processing of greens, fruits

- Organization of the work of the hot shop

- Organization of the work of the soup department of the hot shop

- Organization of the work of the sauce department of the hot shop

- Organization of work of the cold shop

- Organization of the culinary workshop

- Organization of production of flour confectionery products at catering establishments

- Organization of the work of the confectionery shop for the manufacture of products from various kinds test

- Organization of the work of the flour products workshop

- Organization of work of auxiliary production facilities

- Food distribution and presentation lines

- Distribution line formation

- Equipment included in distribution and/or presentation lines

- Heated elements

- Cooled elements

- Accessories

- General requirements for all line elements

- Product quality control

- Essence and tasks scientific organization Labor (HOT)

- The main directions of the scientific organization of labor

- Division and cooperation of labor in the enterprise

- Classification and organization of jobs

- Workplace equipment

- Workplace layout

- Introduction of advanced techniques and methods of work

- Improving labor rationing

- Creation of favorable working conditions

- Design rational modes work and rest

- Strengthening labor discipline

- Vocational training, retraining and advanced training of employees

- The essence and role of labor rationing

- Types of labor standards and their classification

- Normalization methods

- Classification of working hours

- Working time photo

- Timing

The process in the development of machine production, in which the functions of management and control, previously performed by a person, are transferred to instruments and automatic devices. A. p. the basis of development modern industry, general ... ... Great Soviet Encyclopedia

SANITARY ORGANIZATION- SANITARY ORGANIZATION. In the concept of S. o. include usually not only a certain composition of that dignity. personnel, to ry conducts business a dignity. supervision, but also all questions of the structure a dignity. affairs in a particular territory, the volume and forms of activity ... ...

This article lacks links to sources of information. Information must be verifiable, otherwise it may be questioned and removed. You can ... Wikipedia

Price- (Price) Definition of the concept of price (value) and cost of goods Information about the concepts of price, cost of goods, market and purchase prices, production price Content (Price) - fundamental economic category denoting the number of... Encyclopedia of the investor

TUBERCULOSIS- TB. Contents: I. Historical outline ............... 9 II. The causative agent of tuberculosis............. 18 III. Pathological anatomy............... 34 IV. Statistics.................. 55 V. Social significance of tuberculosis....... 63 VI.… … Big Medical Encyclopedia

FOOD LEGISLATION- covers a set of norms and orders established by the central state. by the authorities and individual departments, within the framework of the rights and powers granted to them by the central government and directed; To ensure good quality and usefulness ... ... Big Medical Encyclopedia

waste- 3.1.15 waste material object that is no longer used by the producer or holder, but discarded or released into the environment. Source … Dictionary-reference book of terms of normative and technical documentation

Belarusian Red Cross Society ... Wikipedia

Revenue- (Revenue) Revenue is the result of the enterprise's activities for a certain period, expressed in monetary terms. The concept of revenue, its main forms, calculation of revenue, revenue in accounting, the difference between revenue and profit Contents >>>>>>>>>>> ... Encyclopedia of the investor

FISH- are lower vertebrates that live in water. They belong to two classes of the vertebrate subtype (Vertebrata) of the Chordata type Marsipobranchii and Pisces. The first belong to cyclostomes (Cyclosto mata) lampreys and hagfishes, to the second ... ... Big Medical Encyclopedia

Labor market- (Labor market) The labor market is the sphere of formation of supply and demand for labor Definition of the labor market, definition of the labor force, structure of the labor market, subjects of the labor market, labor market conditions, the essence of the open and hidden market ... ... Encyclopedia of the investor

Radchenko L.A. Organization of production at catering establishments

Chapter 5. ORGANIZATION OF PRODUCTION

Textbook. - Rostov n / a: Phoenix, 2006. - 352 p.

Production infrastructure and its characteristics

The essence of the organization of production is to create conditions that ensure the correct conduct of the technological process of cooking.

At each enterprise, in accordance with the technological process of production, production units are organized that form its production infrastructure.

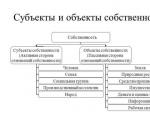

The production infrastructure of an enterprise is understood as the composition of its production units (participants, departments, workshops, productions), the forms of their construction, placement, production relations.

The production structure of an enterprise is influenced by various factors: the nature of the products produced, the features of its manufacturing technology, the scale of production, and the forms of production relations with other enterprises.

By production structure enterprises can be classified into the following types: procurement, manufacturing semi-finished products of varying degrees of readiness to supply them with pre-cooking, culinary and retail stores: pre-cooking, working on semi-finished products; enterprises with a full production cycle, working on raw materials.

Production- This is a large division that unites workshops.

Shop- this is a technologically isolated part of the enterprise in which the completed production process takes place. Depending on the nature of the technological process and the amount of work, workshops may have production sites, departments or production lines.

Production area- this is the part of the enterprise where the completed stage is carried out production process.

The production stage is the technologically completed part of the production process.

Branches- larger production units that can be created in large workshops and industries as an intermediate step between the production site and the workshop or production.

In workshops, departments, production sites jobs are organized.

Workplace- this is a part of the enterprise in which the labor process is carried out by one or a group of workers performing certain operations.

Distinguish between enterprises with a workshop structure and non-shop.

The shop structure is organized at enterprises operating on raw materials, with a large volume of production. Workshops are divided into procurement (meat, fish, poultry, meat and fish, vegetable), pre-cooking (hot, cold), specialized (flour, confectionery, culinary). At public catering establishments working on semi-finished products, a semi-finished products refinement shop, a greenery processing shop are organized.

Technological lines are organized in each workshop. A production line is a production site equipped with necessary equipment for a specific technological process.

The non-workshop structure of production is organized at enterprises with a small volume of the production program, which have a limited range of products at specialized enterprises (snack bars, barbecue, dumplings, dumplings, etc.).

The composition of the premises of catering establishments and the requirements for them are determined by the relevant SNiP. There are five main groups of premises:

Warehouse group - designed for short-term storage of raw materials and products in refrigerated chambers and unrefrigerated storerooms with appropriate storage conditions;

- production group - designed for processing products, raw materials (semi-finished products) and production finished products; the production group includes the main (harvesting and pre-cooking) workshops, specialized (confectionery, culinary, etc.) and auxiliary (washing, bread-slicing) workshops;

- trading group - intended for the sale of finished products and the organization of their consumption (trading halls with distributing and buffets, culinary shops, a lobby with a wardrobe and bathrooms, etc.);

- administrative and domestic group - designed to create normal conditions labor and recreation of employees of the enterprise (director's office, accounting, staff wardrobe with showers and bathrooms, etc.). All groups of rooms are interconnected. The following requirements for the layout of premises have been developed: all groups of premises should be located in the course of the technological process: first, warehouse, production, then retail, administrative and technical premises should be conveniently interconnected with them;

- the mutual arrangement of the main groups of premises should provide the shortest connections between them without crossing the flows of visitors and service personnel, clean and used dishes, semi-finished products, raw materials and waste;

- one should strive for a compact structure of the building, providing for the possibility of redevelopment of premises in connection with a change in production technology;

- the layout of all groups of premises must meet the requirements of SNiP, sanitary and fire regulations;

- all production and storage premises must be impassable, entrances to production and amenity premises - from the side of the utility yard, and to retail premises - from the street; they must be isolated from entrances to residential premises;

- layout commercial premises produced in the direction of movement of visitors; the possibility of reducing their movement and ensuring the evacuation of people in case of fire is envisaged.

Questions for knowledge control

1. What types of production structures can be in public catering establishments?

2. What is the production line in the workshop?

3. What factors influence the successful execution of the manufacturing process?

4. What are the requirements for production facilities?

5. How to check if the area of the workshop where you work meets the standard?

6. What factors determine the microclimate in industrial premises?

7. What factors determine optimal conditions labor?

Organization of workplaces

workplace a part of the production area is called, where the employee performs certain operations, using the appropriate equipment, utensils, inventory, tools. Jobs at public catering enterprises have their own characteristics depending on the type of enterprise, its capacity, the nature of the operations performed, and the range of products.

The area of the workplace should be sufficient to ensure the rational placement of equipment, the creation of safe working conditions, as well as the convenient location of inventory and tools.

Workplaces in the workshop are located along the technological process.

Jobs can be specialized and universal. Specialized workplaces are organized on large enterprises when an employee performs one or more homogeneous operations during the working day.

Medium and small enterprises are dominated by universal workplaces, where several heterogeneous operations are carried out.

The organization of workplaces takes into account the anthropometric data of the structure of the human body, i.e., based on the height of a person, the depth, height of the workplace and the front of work for one employee are determined (Table 12).

When developing sectional modulated equipment, the above factors were taken into account.

Dimensions production equipment should be such that the body and hands of the worker are in the most comfortable position.

As the experience of organizing the workplace of the cook has shown, the distance from the floor to the top shelf of the table, on which the supply of dishes is usually placed, should not exceed 1750 mm (Fig. 6). The optimal distance from the floor to the middle shelf is 1500 mm. This zone is the most convenient for the cook. It is very convenient when the table has drawers for inventory, tools. At the bottom of the table there should be shelves for dishes, cutting boards.

Rice. 6. Workplace of the cook

Sectional modular tables for small-scale mechanization, with a cooled slide and a cabinet. Beside - industrial tables and bathtubs foot wooden racks are installed. For convenience of work, the height of the table should be such that the distance between the worker's elbow and the table surface does not exceed 200-250 mm.

The angle of instantaneous visibility of the object is 18°. In this sector of the review is located what the employee should see instantly. The angle of effective visibility should not exceed 30°. On average, for a person, the viewing angle is 120 °, so the length of the production table should not exceed 1.5 m.

Sufficient area in the area of the workplace eliminates the possibility industrial injuries, provides an approach to the equipment during its operation and repair. It is recommended to observe the following allowable distances when placing the equipment (in m):

| Between two production lines of non-mechanical equipment with a two-way arrangement of workplaces and a line length of up to 3 m. | 1,2 |

| over 3 m. | 1,5 |

| Between wall and process line of non-mechanical equipment | 0,1-0,2 |

| Between wall and mechanical equipment | 0,2-0,4 |

| Between wall and heating equipment | 0,4 |

| Between the technological line of thermal equipment and the distribution line | 1,5 |

| Between the working fronts of thermal and non-mechanical equipment | 1,5 |

| Between the working fronts of the digester sections | 2,0 |

| Between electric boilers installed in line | 0,75 |

| Between production lines of equipment that generates heat | 1,5 |

| Between the wall and the workplace of a vegetable peeler in a vegetable shop | 0,8 |

Each workplace should be provided with a sufficient number of tools, inventory and utensils. Crockery and utensils are selected in accordance with the Equipment Standards, depending on the type and capacity of the enterprise. Requirements are imposed on production equipment: strength, reliability in operation, aesthetics, etc.

Sanitary and hygienic requirements for inventory, utensils, tools are determined by the Joint Venture and SanPiN, according to which utensils, utensils and tools must be made from harmless and safe for human health and environment materials.

Questions for knowledge control

1. What is a workplace?

2. What are the requirements for the size of the area of the workplace?

3. How do jobs differ?

4. What are the main requirements for the organization of jobs?

5. What types of sectional modulated tables can there be?

6. What are the recommended clearances for placing the equipment?

Questions for knowledge control

1. What are the requirements for the location of the vegetable shop?

2. What is technological process vegetable processing?

3. What requirements must be observed when placing equipment?

4. What are the main types of equipment used in a medium-sized vegetable shop?

5. What is the peculiarity of organizing a workplace for cleaning potatoes and root crops?

6. What types of inventory are used in the vegetable shop?

7. Indicate the difference in the organization of a large vegetable shop of a procurement enterprise and a vegetable shop of a medium-sized farm.

8. How are onions, cabbage, herbs and other vegetables processed in the workshop?

9. How is work organized in the vegetable shop?

Labour Organization

The work of the meat shop of the procurement enterprise is organized in one or two shifts, depending on the capacity. In large workshops, separate teams of deboners, tenants, and manufacturers of semi-finished products can be organized. Deboners of the III, IV and V categories are engaged in meat deboning. The trimming of meat is done by trimmers of I, II and III categories. The cutting of semi-finished products is carried out by workers of the III and IV categories. AT meat shops restaurants, canteens, cooks of the III and IV categories work.

In large meat shops, workers during the working day are engaged in homogeneous work, i.e., an operational division of labor is applied. In small meat shops, the cook performs several operations in turn.

Labour Organization

The work of the fish shop is carried out in one or two shifts. At the procurement enterprises, the work is headed by the foreman or foreman. The structure of workers of shop includes manufacturers of semi-finished products of III and IV categories. Workers of the IV category butcher sturgeon fish.

In the fish workshops of restaurants, canteens, cooks of the III and IV categories work; the work of the shop is headed by the production manager or foreman.

Labour Organization

The general management of the workshop is carried out by the head of production, if 5 or more employees work in the workshop, a foreman (cook of IV or V categories) is appointed, who, together with other cooks, carries out the production program. On the basis of the menu plan, he receives raw materials from the production manager, gives the task to the cooks in accordance with their classification, and distributes the products among the members of the team. The foreman monitors the course of the technological process, the consumption rates of raw materials and the output of semi-finished products, the condition and serviceability of the equipment, is responsible for compliance with labor protection rules, safety precautions, and monitors the sanitary condition of the workshop.

In the restaurant, a fifth-class cook prepares semi-finished products for complex and banquet dishes, portioned semi-finished products from beef, lamb, and pork. The cook of the IV category cuts sturgeon fish, seasons poultry carcasses, cuts meat and fish into portions, and makes simple semi-finished products. Cooks of IV and III categories carry out cutting of meat, deboning of parts. A cook of the III category cuts fish of partial species, makes cutlet mass and semi-finished products from it, cuts small-sized semi-finished products.

Questions for knowledge control

1. What is the technological process of meat processing?

2. What is the distinguishing feature in the organization of meat processing in large procurement enterprises from the organization of meat processing in enterprises of medium and small capacity?

3. What semi-finished products are produced in meat shops?

4. What premises are organized in meat shops at large procurement enterprises?

5. Give a description of the organization of the technological process of meat processing in large procurement enterprises.

6. What is the purpose of the conveyor at the workplace of the deboner in large butcher shops?

7. Describe the organization of the deboner's workplace.

8. Describe the organization of the workplace for the preparation of portioned and small-sized semi-finished products.

9. How is the technological process of preparing chopped semi-finished meat products organized?

10. What kind of mechanical equipment is used in the processing of meat in large meat shops and meat shops of medium capacity?

11. How is work organized in meat shops?

12. What is the purpose of the poultry shop?

13. Where are the poultry shops organized?

14. What are the three main areas organized in the poultry shop?

15. Describe the organization of poultry defrosting.

16. Where is the bird burned?

17. How is the process of evisceration of poultry organized in the poultry shops?

18. How is the process of preparing portioned and chopped semi-finished products from poultry organized?

19. How is the processing of by-products organized in poultry shops?

20. List the tools and equipment used in the processing of poultry.

21. What are the terms of storage and sale of semi-finished poultry products?

22. In which workshop is poultry processed in restaurants and canteens?

23. List the assortment of semi-finished fish products manufactured at large procurement enterprises.

24. What operations does the technological process of processing fish with a bone skeleton consist of?

25. In what distinctive features in the organization of the technological process of processing fish with a bone skeleton in large fish shops from the processing of fish in shops of medium and low power?

26. How is defrosting of frozen fish with a bone skeleton organized?

27. Describe the organization of jobs for gutting fish.

28. What mechanical equipment is used when cutting fish with a bone skeleton?

29. What is fish fixation for?

30. Describe the organization of the workplace for the preparation of portioned, small-sized and cutlet mass products.

31. How is the process of processing sturgeon fish organized, what is its peculiarity?

32. Conditions and terms of storage of fish semi-finished products.

33. Describe the organization of fish processing in catering establishments of medium and small capacity.

34. How is work organized in the fish shop?

35. What is the peculiarity of the organization of the work of the meat and fish shop?

36. How is the meat processing process organized in the meat and fish shop?

37. How is the workplace organized for the preparation of portioned and small-sized semi-finished products?

38. How is the workplace organized for the preparation of chopped semi-finished meat products?

39. How is the fish processing process organized in the meat and fish shop?

40. Where are semi-finished product refinement workshops organized and what is their purpose?

41. What separate jobs are organized in the semi-finished product refinement shop?

42. What equipment is used in the workshops for the completion of semi-finished products?

43. How is the workplace organized for the finalization of semi-finished meat products in the pre-cooking shop?

44. How is the processing of by-products organized in the workshop for the completion of semi-finished products?

45. How is poultry processing organized in the semi-finished product processing shop?

46. How is the preparation of semi-finished fish products organized in the semi-finished products processing workshop?

47. Describe the organization of the work of the greenery processing shop.

Labour Organization

Since the work in the hot shop is very diverse, cooks of various qualifications must work there. Recommended the following relation cooks in the hot shop: VI category - 15-17%, V category - 25-27%, IV category - 32-34% and III category - 24-26%.

The production team of the hot shop also includes kitchen utensils washers, kitchen auxiliary workers.

The cook of the VI category, as a rule, is a foreman or a senior cook and is responsible for organizing the technological process in the workshop, the quality and compliance with the yield of dishes. He monitors compliance with the technology of cooking and culinary products, prepares portioned, specialty, banquet dishes.

The 5th class cook prepares and decorates dishes that require the most complex culinary processing.

The cook of the IV category prepares the first and second courses of mass demand, sautés vegetables, tomato puree. A cook of the III category prepares products (cuts vegetables, cooks cereals, pasta, fries potatoes, cutlet mass products, etc.).

In small hot shops, the work of the shop is headed by the head of production.

Questions for knowledge control

1. Which enterprises organize hot shops?

2. What technological processes are carried out in the hot shop?

3. Describe the location of the hot shop at the catering establishment.

4. On what grounds are dishes made in a hot shop distinguished?

5. What requirements must meet the dishes of the hot shop?

6. On the basis of what is the production program of the hot shop?

7. What are the requirements for the microclimate of the hot shop?

8. What determines the operating mode of the hot shop?

9. Taking into account what factors are selected equipment for the hot shop?

10. What is the advantage of using sectional modulated equipment?

11. Methods for arranging equipment in a hot shop.

12. What types of sectional modulating production tables and other types of non-mechanical equipment can be used in a hot shop?

13. What specialized departments stand out in the hot shop?

14. What are the stages of the technological process of making soups?

15. Give examples of water norms and time for preparing different types of broths of different concentration.

16. What kinds and types of heating equipment are used in the soup department of the hot shop? What are they made of?

17. What is the distance between the thermal equipment line and the non-mechanical equipment line?

18. Describe the organization of the technological process of making soups.

19. What is the difference between the organization of workplaces for preparing soups in a restaurant and the organization of workplaces in a canteen?

20. What equipment is used to make puree soups?

21. When preparing clear broths, what additional jobs can be organized?

22. What is the purpose of the sauce department?

23. List the types and types of the main equipment of the sauce department of the hot shop.

24. What is the advantage of using microwave devices in a hot shop?

25. In what technological lines can the equipment of the sauce department be grouped?

26. How is work organized in a hot shop?

Labour Organization

The operating mode of the cold shop is set depending on the type of enterprise and its mode of operation. If the duration of the work of the enterprise is 11 or more hours, the workers of the shop work according to a stepped, two-brigade or combined schedule. The general management of the workshop is carried out by a foreman or a responsible worker from cooks of the VI or V category.

The foreman organizes work on the implementation of the production program in accordance with the menu plan. In the evening, labor-intensive dishes are prepared: jellies, aspic dishes, kissels, compotes, etc.

The time for preparation of work at the beginning of the working day is used for the selection of dishes, inventory, and the receipt of products in accordance with the production task. With a good organization of production, the time to prepare the work should be no more than 20 minutes. Chefs receive assignments according to their qualifications. The foreman monitors compliance with the rules for the technology of preparing cold and sweet dishes, the schedule for their release in order to eliminate interruptions in serving visitors.

In cold shops with a large amount of work, an operational division of labor is carried out, taking into account the qualifications of cooks.

Cooks of the III category are engaged in the preparation of products that make up the dishes (cooking vegetables, boiling or frying meat and fish semi-finished products, cutting vegetables, processing herring).

Cooks of the IV category are engaged in the preparation of dressings, portioning and decoration of cold dishes of mass demand (vegetable, fish, meat salads, vinaigrettes, jellies, marinated fish, etc.), sweet dishes.

Cooks of the 5th category prepare and decorate complex dishes (jelly, stuffed fish, galantine, assorted fish and meat, jellies, mousses, etc.).

At the end of the work shift, the cooks report on the work done, and the foreman or responsible cook draws up a report on the sale of dishes per day to the trading floor, buffets and branches.

Questions for knowledge control

1. Where is the cold shop organized?

2. What is the purpose of the cold shop? List the range of cold shop products.

3. What is the cold shop production program based on?

4. Describe the location of the cold shop.

5. What features should be taken into account when organizing a cold shop?

6. What mechanical equipment is used in the cold shop?

7. List the means of small-scale mechanization used in the cold shop.

8. What non-mechanical equipment is used in the cold shop?

9. List the types and types of cold equipment used in the cold shop.

10. What are the requirements for the layout of the cold shop?

11. List the inventory, tools used in the cold shop.

12. What technological lines of cooking can stand out in a cold shop?

13. What separate jobs are organized in large cold shops?

14. Describe the organization of the workplace for preparing salads and vinaigrettes.

15. Describe the organization of the workplace for the processing of gastronomic products.

16. Describe the organization of the workplace for preparing jellied dishes.

17. Describe the organization of workplaces for making sandwiches.

18. How is the preparation of cold soups organized in a cold shop?

19. Describe the preparation of sweet dishes in a cold shop.

20. What equipment is used to make soft ice cream and to store and dispense ice cream?

21. How is work organized in a cold shop?

22. What are the technological lines in the sauce department intended for, what do they consist of?

23. How is the organization of jobs in the sauce department in a restaurant different from the organization of jobs in the canteen?

24. Describe the organization of the technological process of preparing second courses in the sauce department.

25. What are the terms for the implementation of second courses.

26. What rules should be observed in case of forced storage of leftover food?

27. What dishes and side dishes are not allowed to be left for the next day?

28. What safety measures established by biomedical requirements and sanitary standards apply to food products?

29. List the types of kitchen utensils used in the hot shop.

30. List the inventory, tools used in the hot shop.

31. What jobs can be organized in the sauce department of the hot shop?

32. List the types and types of equipment used for frying and sautéing foods.

33. How to organize the workplace of a cook preparing boiled, poached, stewed dishes?

34. How is the process of cooking cereals and pasta organized?

35. What should be taken into account when choosing stove-top boilers for cooking cereals of various consistency? Give examples.

36. Terms of sale of sauces.

Labour Organization

The mode of operation of the culinary workshop depends on its production capacity and the range of products. As a rule, culinary workshops work in one or two shifts. The capacity of the workshop is determined by the quantity of products produced in kilograms, pieces in accordance with the established production program. The production program of the workshop for a particular day depends on the requests received from other enterprises. Chefs of various qualifications work in the main workshop. The work of the shop is headed by the head of the shop or foreman, who is responsible for compliance with the technology for preparing products, for the quality and safety of products; carries out the arrangement of cooks, monitors the timing of the manufacture, storage and sale of finished products.

Questions for knowledge control

1. What is the purpose of the culinary workshop?

2. What premises are included in the culinary workshop?

3. List the product range of the cold department of the culinary shop.

4. What equipment is used in the cold department of the culinary workshop?

5. List the assortment of culinary products of the hot department of the culinary shop.

6. How are jobs organized in the hot section of the culinary workshop?

7. How is work organized in the culinary workshop?

Labour Organization

The confectionery shop is managed by the head of the shop. He introduces the foremen to the range of manufactured products, distributes raw materials between the teams, and controls the technological process of preparing confectionery products.

In confectionery shops, as a rule, a linear schedule is used. In large workshops, work is organized in two shifts, in small enterprises - in one shift. Brigades are organized either by type of product (one prepares products from yeast dough; the other cakes, pastries), or by operations of the technological process (kneading, cutting and baking products; finishing products). Two or three teams work in each shift, depending on the capacity of the shop. Among the members of the brigade, an operational division of labor is carried out.

Confectioners of the V category make figured, custom-made cakes and pastries. They carry out the preparation and quality control of raw materials, fillings, finishing semi-finished products, preparation of dough, molding of products, and artistic finishing of products.

Confectioners of the IV category make various cupcakes, rolls, cookies of the highest grades, complex cakes and pastries.

Confectioners of the III category make simple cakes and pastries, bakery products. They prepare various types of dough, creams, fillings.

Qualification requirements for a confectioner:

The confectioner must have an elementary or secondary professional education;

- know the recipes and production technology of flour confectionery and bakery products from various types of dough, finishing semi-finished products;

- know the commodity characteristics of raw materials, types of flavoring and aromatic substances, rippers and dyes allowed for the manufacture of confectionery;

- observe the sanitary and hygienic conditions for the production of flour confectionery products, their shelf life, transportation and sale;

- know the organoleptic methods for assessing the quality of confectionery products;

- know the methods and techniques of highly artistic finishing of complex types of confectionery;

- know the principles of operation and operating rules technological equipment used in the manufacture of confectionery.

Qualification requirements for a confectioner are specified in accordance with the requirements of the industry standard OST 28-1-95 “Public catering. Requirements for "production personnel"; this standard is used in the certification of catering services.

Confectioners of the II category perform individual work in the process of making cakes, pastries, prepare syrups and creams.

Confectioners of the 1st category perform work under the guidance of confectioners of the highest category, remove baked goods from baking sheets, clean confectionery sheets, baking sheets and forms.

Bakers II and III categories bake and fry confectionery and bakery products. They determine the readiness of semi-finished products for baking, prepare the seasoning and lubricate the products. The baker must know the technological process, modes and duration of baking confectionery; to know the norms for the output of finished products, the factors affecting the upek, the mode of cooling of baked products; know the device, the principles of the device and the rules for operating the equipment being serviced.

Confectioners must be aware of the responsibility for the work performed.

The head of the shop and foremen monitor the rational organization of labor in the shop.

The work of confectionery shops is carried out in accordance with the planned target for the production of products.

Questions for knowledge control

1. Where are confectionery shops organized?

2. How are confectionery shops classified in terms of productivity and range of products?

3. What is the difference between the range of manufactured products in confectionery shops of small and large capacity?

4. What are the stages of the technological process for the manufacture of flour confectionery?

5. What is the composition of the premises can have high-capacity confectionery?

6. List the types and types of equipment used in confectionery shops.

7. What eggs are forbidden to be used in the manufacture of confectionery?

8. How are eggs processed before use in pastry shops?

9. What personal hygiene rules should workers observe before eggs are broken, after they are processed?

10. How is flour sifting organized in confectionery shops?

11. Describe the organization of kneading and preparation of yeast dough.

12. Describe the organization of the preparation of biscuit dough.

13. Describe the organization of jobs for the preparation of puff pastry.

14. How is the preparation of custard dough organized?

15. How are working places for cutting dough organized?

16 What tools and inventory are used to cut the dough?

17. Describe the organization of the workplace for cutting yeast dough.

18. How is baking of confectionery organized?

19. Give examples temperature regime baking products from various types of dough.

20. How is the preparation of finishing semi-finished products organized?

21. What inventory, tools are used when decorating cakes and pastries?

22. How is the washing of dishes, inventory of the confectionery shop organized?

23. How should piping bags be handled after use?

24. Terms and conditions of storage of confectionery products.

25. What rules for the transportation of confectionery products must be observed?

26. How is work organized in confectionery shops?

27. What kind of work do confectioners of the V and IV categories perform?

28. What kind of work do confectioners of I, II and III categories perform?

29. List qualification requirements to the confectioner.

30. What kind of work do bakers II and III categories?

Workshops

After studying the chapter "Organization of production", it is recommended to conduct practical exercises on compiling algorithms for workplaces and production lines in various workshops (it is advisable to conduct the lesson in production or as a tour of production with the implementation of the specified task on your own); analysis and solution of production situations related to the organization of work of production shops of various types and classes; selection of equipment and inventory for various workshops (taking into account equipment standards).

Distribution work organization

Distribution at public catering enterprises performs the function of selling ready meals. The quick service of visitors largely depends on the work of the dispensing room, which means an increase in bandwidth sales area and an increase in the output of own production.

Distribution is an important area of production, since it is here that the production process is completed when the finished product is dispensed. The fuzzy work of the dispensary can lead to a decrease in the quality of ready-made dishes and worsen customer service.

The distribution should have a convenient connection with the hot and cold shops, trading floor, bread slicer and washing tableware, and in the restaurant - with a service, buffets, bar counter.

By its location, the distribution can be a continuation of the hot shop, being in the same room with it.

In restaurants, small and medium-sized enterprises, the distribution of finished products is entrusted to the chefs who prepared it. This increases their responsibility for the quality, design and correct yield of dishes. At self-service enterprises, when the trading floor is open for a long time, the dishes are released by the distributors.

Distribution lines are classified according to three criteria: design features the equipment used, the range of products sold and the way it is sold to consumers (Table 18).

Table 18

Distribution work organization

1. Purpose and location of distribution.

2. Classification of distribution lines.

3. Characteristics of mechanized distribution lines.

Radchenko L.A. Organization of production at catering establishments

Chapter 2. CLASSIFICATION OF PUBLIC CATTERING ENTERPRISES. FEATURES OF ACTIVITY

Rational placement of a network of public catering establishments

Rational placement of a network of public catering enterprises is the creation of the greatest convenience for the population when organizing public catering at the place of work, study, residence, recreation and while traveling, as well as ensuring the high efficiency of the enterprise itself. In a competitive environment, the location of a public catering establishment has great importance, therefore, it is necessary to take into account the following factors: the population of the city (district), the location of industrial enterprises, administrative, socio-cultural and educational institutions; availability of enterprises retail network; purchasing power of the population and demand for catering products; accepted standards for locating a network of public catering establishments.

Modern cities are characterized by a high concentration of population, housing density, the presence in most cases of clearly defined four main zones - industrial, housing-administrative, communal-warehouse and recreation.

AT industrial area factories, factories and other production facilities are located. Characteristic of this zone is the placement at manufacturing enterprises canteens, grocery stores. The standard in workers' canteens is 250 seats per 1,000 employees.

The housing and administrative zone includes residential areas, administrative, public institutions and educational institutions. This zone houses student, school, public canteens, cafes, restaurants, bars, snack bars, businesses for home delivery, and culinary shops.

For proper organization power supply, the standard of seats must be observed:

In school canteens - 250 seats per 1000 students;

- in student canteens - 180 seats per 1000 students.

In the utility warehouse area all kinds of warehouses, bases, refrigerators, food industry enterprises are located. In this zone, it is recommended to locate procurement factories, semi-finished products factories, specialized workshops for the production of semi-finished products to supply other catering establishments and retail chains with their products.

In recreation areas there are parks, gardens, sports complexes, entertainment enterprises, beaches. A small number of stationary enterprises with winter and summer halls can be created here, but a significant part is occupied by summer-type enterprises (seasonal), which have a collapsible structure. The main types of enterprises are all kinds of snack bars, cafes, restaurants, bars.

Of no small importance is the organization of pedestrian and transport systems: where large flows intersect, larger and larger ones are placed. Depending on the population, cities are divided into: small - up to 50 thousand people, medium - over 50 and up to 100 thousand people , large - over 100 and up to 250 thousand people, large - over 250 and up to 500 thousand people; the largest - over 500 thousand people, megacities - over 1 million people.

When planning the opening of new catering establishments of any organizational and legal form, it is necessary to take into account all the factors of rational location of enterprises, so that in the future the enterprise will work effectively, be in demand and become profitable. restaurants, bars, cafes, snack bars, canteens.

Depending on the population, cities are divided into: small - up to 50 thousand people, medium - over 50 and up to 100 thousand people, large - over 100 and up to 250 thousand people, large - over 250 and up to 500 thousand people; the largest - over 500 thousand people, megacities - over 1 million people.

Residents of large cities often use catering services at the place of work, study, as a rule, remote from their place of residence.

With the growth in the number of cities, the standard for the number of seats in catering establishments per every 1000 people of the urban population is also growing. So, for example, if the average standard for places in a network of public catering establishments is 28 places per 1,000 people for small towns, then for large cities it grows from 36 to 50 places per 1,000 people.

The rational distribution of the public catering network involves taking into account visitors, who are much more numerous in large cities than in small ones. As experience shows, in large cities every fourth or fifth visitor to public catering establishments is a visitor.

The rational location of enterprises is significantly influenced by the daily and periodic demand of the population. Canteens, take-out businesses, and culinary shops are needed to meet daily demand. Such enterprises are recommended to be located in places of high population density with a radius of 500 m from each other, in cities with low population density - at a distance of 800 m.

Products of periodic demand of consumers are provided mainly by snack bars and cafes, such as general type, and specialized, restaurants, bars. The radius of consumer service by such enterprises is 800 m, and for large restaurants - 1.0-1.5 km.

It is also necessary to take into account the approximate ratio (in%) between the types of public catering establishments for the city: the most snack bars and cafes - 40%, the number of bars - 20-25%, restaurants - 25-30%, the number of public canteens - 5-10 decreases %.

When planning the opening of new catering establishments of any organizational and legal form, it is necessary to take into account all the factors of rational location of enterprises, so that in the future the enterprise will work effectively, be in demand and become profitable.

Questions for knowledge control

1. What is the catering business intended for?

2. What organizational and legal forms can public catering enterprises have?

3. What founding documents must have businesses to register?

4. What functions does a public catering enterprise perform?

5. What are the features of production and trade activities have public catering?

6. What services can catering establishments provide?

7. On what grounds are catering establishments classified?

8. How are enterprises divided according to the nature of production?

9. How are enterprises divided according to the range of products?

10. On what grounds are enterprises divided into classes?

11. What catering establishments are divided into classes?

12. What are the signs of classes.

13. How are enterprises divided by operating time?

14. How are enterprises divided according to the place of operation?

15. How are enterprises divided depending on the contingent served?

16. On what basis are catering establishments divided into types?

17. Name the main types of catering establishments.

18. What requirements do catering services meet?

19. Give a description of the harvesting factory, the plant of semi-finished products.

20. Describe the kitchen factory.

21. What is a food plant?

22. What are specialized workshops for?

23. Describe the canteen as a type of catering establishment.

24. On what grounds canteens are distinguished?

25. What are the requirements for a canteen as a type of catering establishment?

26. Describe a restaurant as a type of catering establishment.

27. What are dining cars for and what are their features?

28. Describe the bar as a type of catering establishment.

29. Describe the cafe as a type of catering establishment.

30. What is the purpose of the cafeteria and its features?

31. Describe the diner.

32. What specialty eateries can you name?

33. Give the characteristic of specialized eateries.

34. What are the enterprises for the sale of finished products at home, the features of their organization?

35. What public catering enterprises are small retail and what are the requirements for them?

36. Describe a grocery store.

37. What does the rational placement of a network of public catering establishments mean?

38. What zones are modern cities divided into?

39. Give a description of each zone and what enterprises are recommended to be located in them.

40. What factors should be considered when placing enterprises?

41. What enterprises are in daily and periodic demand and how is this taken into account when placing public catering establishments?

Storage and release of products

When storing raw materials and products, the requirements of sanitary standards must be observed in accordance with SanPiN 42-123-4117-86 “Conditions, terms of storage of especially perishable products”. Responsibility for the observance and control of the Sanitary Rules is borne by the heads of enterprises producing and transporting perishable products, public catering and trade enterprises. Control over compliance with the Sanitary Rules is assigned to the bodies of the Sanitary and Epidemiological Service.

Of great importance is the correct placement of goods, taking into account the maximum use of the warehouse area, the possibility of using mechanisms, ensuring the safety of personnel, and prompt accounting of inventory items.

To prevent loss and spoilage of products, it is necessary to ensure the optimal mode of storage of goods in warehouses in accordance with their physical and chemical properties. The storage mode is a certain temperature, air velocity, relative humidity. During storage, you should strictly monitor compliance with the terms of the sale of products, especially perishable ones. So, large-sized semi-finished products from meat are stored for 48 hours at a temperature of 2-6 °, portioned semi-finished products without breading - 36 hours; portion breaded semi-finished products - 24 hours, minced meat semi-finished products - 12 hours; fish of all types is stored for 48 hours at a temperature of 0-2 °; frozen fish - 24 hours at the same temperature; lactic acid products are stored for no more than 36 hours at a temperature of 2-6 °.

There are several ways to store and stack raw materials and products:

- Shelving- products are stored on shelves, racks, in cabinets; with this method, it is protected from dampness, since air is accessed to the lower layers. In this way, they store food in boxes, butter, cheese, bread, bottled wines (in horizontal position for wetting plugs).

- stacked- products are stored on pallets; this is how products are stored in containers that can be stacked in a high stable stack no more than 2 m high; bags with sugar, flour are laid flat, no more than 6 bags high.

- box- in boxes store fruits, vegetables, eggs, etc.

- Bulk- products are stored in bulk - in bins, chests, containers, bins without containers, and on the side of the walls and floor, a space of 10-20 cm is left for free air access; potatoes are stored in this way (height no more than 1.5 m), root crops (0.5 m), onions (0.3 m).

Suspension- used to store raw materials and products in a suspended state, this is how smoked meats are stored, sausages. Meat in carcasses, half carcasses, quarters is stored hanging on tinned hooks, without contact between carcasses and walls (Fig. 2).

Rice. 2. Hooks for meat (gastronomic):

a - "eight"; b - "swivel"

To ensure proper storage, do not store: food products outside the warehouse (in the corridors, at the unloading area, etc.); finished products, gastronomic products - together with raw ones; goods that easily absorb smell (eggs, dairy products, bread, tea, etc.) - with pungent goods (fish, herring, etc.); products with empty containers.

Violation of the established rules and regimes of storage, transportation and distribution of goods may lead to commodity losses. They are divided into two types: standardized and non-standardized.

Normalized losses- loss within natural loss(shrinkage, weathering, cracking, spray, spill). Natural decline occurs as a result of changes physical and chemical properties products during storage. Attrition rates are set for all types of products. The natural loss is written off during the inventory period, if a shortage is found in the warehouse. Calculations for attrition are made by the accounting department and approved by the director of the enterprise.

To non-standardized losses include fight, spoilage of products. These losses arise as a result of unsatisfactory conditions for the transportation and storage of products, as well as due to mismanagement of storeroom workers. Losses from the fight and damage to products are documented by an act no later than the next day after they are established. The cost of damaged products is recovered from the guilty persons.

Release of products is one of the important final operations of the warehouse cycle. From the warehouses of public catering establishments, products are sold to production, to branches, canteens according to the requirements drawn up by financially responsible persons (manager of production, bartenders). Based on the requirement, the accounting department draws up invoice requirements, which are signed by the chief accountant and the head of the enterprise, and after the release of goods - by the warehouse manager and the materially responsible person who received the goods. Upon receipt of products from the warehouse, they are checked for compliance with their requirements-waybills in terms of assortment, weight and quality, as well as the serviceability of the container.

Before the release, the storekeeper opens the container, checks the quality of the goods, sorts and cleans them. When dispensing products, the storekeeper observes the order: the goods that arrived earlier are released first, dry products first, then from the refrigerated chambers, and lastly - potatoes, vegetables.

The storekeeper is obliged to prepare measuring containers, weighing equipment, inventory, tools.

Upon receipt of the products, materially responsible persons must make sure that the scales are in good condition, check the tare weight, product quality, the timing of the sale of goods sold, monitor the accuracy of weighing and records in the invoice.

Questions for knowledge control

1. What is the importance of a rational organization of supply in public catering?

2. What are the requirements for the organization of food supply?

3. What is the source of food for catering establishments?

4. Name the types of wholesale bases by specialization and purpose.

5. What is the function of brokers, sales agents?

6. What main document defines the rights and obligations of the parties for the supply of all types of products?

7. What are the main sections of the supply agreement?

8. Who organizes the supply chain at catering establishments?

9. What does the logistic approach to the work of the enterprise mean and its significance?

10. What tasks need to be solved and work done to provide catering establishments with food?

11. What criteria should be considered when choosing suppliers?

12. Basic principles of commodity circulation.

13. List the main operations of product distribution in public catering.

14. What does the concept of "warehouse links" mean?

15. What forms of supply are used in catering?

16. What methods of supply are used in public catering?

17. Name the types of routes for the delivery of products, their features.

18. What role does transport and its requirements play in the supply of food?

19. How is the acceptance of food products organized?

20. Describe the stages in the acceptance of food.

21. What items are prohibited from being accepted?

22. What commodity stocks are recommended to have at catering establishments?

23. How is the material and technical supply of public catering enterprises organized?

24. What are the requirements for the organization of logistics?

25. What is the peculiarity of the fair form of supply?

26. Describe the auction form of trade.

27. Give a description of the current standards for equipping equipment, utensils and inventory.

28. What is the purpose of storage facilities?

29. How are warehouses divided by classification?

30. Name consistently warehouse operations.

31. How is the storage area calculated?

32. What determines the number of storage facilities at catering establishments? List them.

33. List the equipment of storage facilities.

34. List inventory, warehouse tools.

35. What are the requirements for the layout of storage facilities?

36. What are the space-planning requirements for warehouses?

The essence of operational planning is to draw up an enterprise program. The issues of planning the production program are handled by production managers (deputies), heads of production workshops, foremen, and accountants.

4.1. Operational planning of the work of the production of blank enterprises

To draw up the production program of a procurement enterprise, the following data are required: the range of products (semi-finished products, culinary products, flour confectionery products); technical equipment of the enterprise; a network of public catering and retail chains that have entered into contracts with a harvesting enterprise or specialized harvesting shops; the range and quantity of products required for these enterprises; the volume of semi-finished products produced by food industry enterprises for pre-cooking enterprises.

Operational planning of production is carried out in a certain sequence, therefore, at each stage, it is necessary to create certain organizational conditions that contribute to the proper organization of the technological process, rational organization work, the clear performance of each employee of their duties.

An important place in the operational planning of production is occupied by the dispatching service. The operational planning of the production of a blanking enterprise and specialized blanking shops is carried out in the following sequence. The enterprises with which the contract is concluded make daily orders for semi-finished products, culinary and flour confectionery products and transfer them to the procurement enterprises in the dispatch services (departments). The received orders in the dispatching service are summarized for all types of products and transferred to the shops in the form of a daily production plan. One copy of the order goes to the expedition for subsequent order picking. Applications are accepted one day before their execution. This is explained by the fact that the production workshop needs to obtain in advance the required range and quantity of raw materials, products for the implementation of the technological process of manufacturing products on demand.

Semi-finished products and culinary products are produced in accordance with the specifications, OSTs, as well as the data of the Collection of norms for waste and losses during cold and heat processing of raw materials.

To calculate the yield of semi-finished vegetable products, use the formula:

where Q mp - the number of semi-finished meat products of this type (pieces, servings, kg);

Q m - mass of meat (gross), from which semi-finished products are produced, kg;

β - %, taking into account the specific gravity of the corresponding parts of the meat (in a stripped form) during the culinary cut;

g p - mass of a portion of a semi-finished product, kg (according to the Collection of recipes).

Example. Determine the number of servings of azu with a net weight of 119 g, which can be prepared from 500 kg of beef of the 1st category. The output of the side and outer pieces of the hip used for the preparation of azu is 10.1%.

Number of servings of azu = 500 ∙ 10.1 / 100 ∙ 0.119 = 424.

An example of determining the range and output of semi-finished products from 6 tons of beef of the 1st category is given in Table. 1, which indicates the percentage of parts of beef meat, their output in kilograms, the name and number of semi-finished products prepared from each part. The calculation in the table is made for the first shift, which processes 60% of the daily volume of raw materials.

Calculation of the output of semi-finished products from 6 tons of beef of the 1st category

| Name of carcass parts | Exit | Name of semi-finished products | Weight of one serving (net) | Number of semi-finished products, pcs. (servings) | Actual consumption meat for the production of semi-finished products, kg | |

| % | weight, kg | |||||

| Dorsal part (thick edge) | 1,7 | Entrecote | 120,0 | |||

| Lumbar (thin edge) | 1,6 | beef stroganoff | 77,94 | |||

| Hip part: | ||||||

| top piece | 2,0 | Rump steak | 42,0 | |||

| 77,99 | ||||||

| inner piece | 4,5 | Zrazy natural | 120,0 | |||

| Roasting | 75,0 | |||||

| Meat for barbecue | 75,0 | |||||

| side piece | Beef | |||||

| outer piece | 6.1 | Azu | 356,0 | |||

| Blade part: | ||||||

| shoulder | 2,0 | |||||

| shoulder... | 2,5 | Goulash | 269,94 | |||

| Subscapular part | 2,0 | For cooking | - | - | ||

| Brisket (pulp)... | 2,8 | Goulash | 167,95 | |||

| Pokromka | 4,1 | - | - | 246,0 | ||

| cutlet meat | 40,3 | Chopped beefsteak | 1418,0 | |||

| Chopped cutlets | 1000,0 | |||||

| Yield of large-sized semi-finished products and cutlet meat | 73,6 | |||||

| Bones | 22,2 | For cooking broths | - | - | ||

| Tendons, cartilage | 3,2 | |||||

| Technical stripping and cutting losses | 0,5 | |||||

| Storage loss | 0,4 | |||||

| cutting loss | 0,1 | |||||

| Total... | 100,0 |

At a procurement enterprise, in order to control the correct use of raw materials and the number of semi-finished products produced, the head of the shop draws up an act for cutting the mass of raw materials into large-sized semi-finished products in accordance with form 61. The act indicates the name and quantity of the raw materials received by the shop in kind and value terms, the output rates of large-sized semi-finished products according to Collection of recipes in percentages and kilograms. The act is signed by the head of the shop, checked in the accounting department and approved by the director of the enterprise.

The work of confectionery shops is carried out in accordance with the planned target for the production of products. Based on the raw materials and orders available in the pantry of the enterprise, the head or foreman of the confectionery shop draws up an order order in form 76. An order order is a document for calculating the production task for manufacturing products on order: determining the need for raw materials. The work order serves as the basis for the release of raw materials from the pantry for production (see Table 2).

table 2

Work order for the manufacture of confectionery

| Item code | Total, kg, l | |||||||||||

| Name | Biryu-sinka cake | Cake Prague | Cake Prague | Wenceslas cake | Wenceslas cake | Zdenha cake | Cake Biscuit | Cake Biscuit | Cake Nut | Pastry Potato sprinkled | ||

| Output rate, g | ||||||||||||

| Ordered, Quantity, Im | ||||||||||||

| Required amount raw materials, kg: | 34,125 | 2,4375 | 36.56 | |||||||||

| dietary egg 1st category yolk | 10.062 | 3,437 | 0,2455 | 2,205 | 15,95 | |||||||

| protein | 18,711 | 18.71 | ||||||||||

| melange | 1,9495 | 42,168 | 3,012 | 28,296 | 26,862 | 2,442 | 8.811 | 8,33 | 119.9 | |||

| butter of the highest grade | 27.293 | 1,9495 | 29,24 | |||||||||

| butter of the highest or 1st grade | 23,793 | 2,163 | 6,815 | 32,37 | ||||||||

| higher butter. 1st grade, amateur | 27,999 | 61,362 | 4,383 | 39.204 | 11,304 | 144.25 | ||||||

| natural milk | 26,838 | 1,917 | 17.154 | 45.9 | ||||||||

| condensed milk | 14,28 | 1.02 | 9,515 | 0,865 | 3,528 | 2.725 | 21,9 | |||||

| cream | 6,705 | 6,7 | ||||||||||

| agar | 0,225 | 0,225 | ||||||||||

| vanillin | 0.0042 | 0.0003 | 0.0045 | |||||||||

| lemon acid | 0,045 | 0.045 | ||||||||||

| rum essence | 0,027 | 0.033 | 0,003 | 0,055 | 0.072 | |||||||

| powdered sugar | 12,694 | 1.154 | 3.078 | 4,49 | 21,42 | |||||||

| salt | 0,072 | 0,072 | ||||||||||

| granulated sugar | 37,174 | 29,988 | 2.142 | 62,734 | 4,481 | 43,317 | 26.939 | 2.449 | 6.876 | 4,9 95 | 221.4 | |||||||||||||||||||||||||

| essence | 0.035 | 0,0025 | 0.090 | 0,165 | 0,015 | 0,027 | 0,05 | 0,39 | ||||||||||||||||||||||||||||

| vanilla powder | 0,158 | 0,287 | 0,0205 | 0.231 | 0,021 | 0,07 | 0,78 | |||||||||||||||||||||||||||||

| starch | 3,836 | 0.274 | 2.448 | 3,223 | 0.293 | 11,07 | ||||||||||||||||||||||||||||||

| nuts | 4,797 | 5,446 | 0,389 | 4.851 | 4.743 | 20.23 | ||||||||||||||||||||||||||||||

| syrup | 1.134 | 0,081 | 5,292 | 0,373 | 2,286 | 0,684 | 9.86 | |||||||||||||||||||||||||||||

| jam | 6,573 | 0,4695 | 7,04 | |||||||||||||||||||||||||||||||||

| canned fruits | 18,662 | 1,333 | 13,842 | 33.84 | ||||||||||||||||||||||||||||||||

| chocolate glaze | 2.277 | 1.428 | 0,102 | 3,8 | ||||||||||||||||||||||||||||||||

| cocoa powder | 5.166 | 4,403 | 0,3145 | 4,214 | 0,301 | 1.971 | 0,22 | 0.02 | 0,305 | 16,9 | ||||||||||||||||||||||||||

| candied fruit | 1,98 | 0.18 | 2,2 | |||||||||||||||||||||||||||||||||

| lemon slices | 1,44 | 1.44 | ||||||||||||||||||||||||||||||||||

| wine | 1.026 | 3,066 | 0.219 | 2,691 | 3,344 | 0,304 | 0.036 | 0,025 | 10.7 | |||||||||||||||||||||||||||

Received by the head of the shop (signature)

Chapter 4. OPERATIONAL PRODUCTION PLANNING AND TECHNOLOGICAL DOCUMENTATION

4.2. Operational planning at enterprises with a full production cycle

Each public catering enterprise must have a monthly turnover plan approved, and on the basis of this plan, a production program for the day is drawn up.

In restaurants where the range of dishes is very large, the menu mainly includes ordered a la carte dishes, so it is difficult to plan in advance the number of dishes released, but given past experience, and in the restaurant you can plan the release of the number of semi-finished products (when processing meat, poultry, fish) and how much food you need to get per day from storage facilities.

At catering establishments with a certain contingent of consumers (canteens at manufacturing enterprises, educational institutions, children's institutions, rest homes, etc.) you can more clearly plan the work of production for every day.

Operational planning of production work includes the following elements:

Drawing up a planned menu for a week, a decade (cyclic menu), on its basis, the development of a menu plan that reflects the daily production program of the enterprise; preparation and approval of the menu;

- calculation of the need for products for the preparation of dishes provided for by the menu plan, and drawing up requirements for raw materials;

- registration of the requirement-invoice for the release of products from the pantry for the production and receipt of raw materials;

- distribution of raw materials between workshops and determination of tasks for cooks in accordance with the menu plan.

First step operational planning is the preparation of a planned menu. The presence of a planned menu makes it possible to provide a variety of dishes on the days of the week, avoid repetition of the same dishes, ensure a clear organization of the supply of raw materials and semi-finished products, timely sending applications to wholesale bases, industrial enterprises, properly organize the technological process of cooking and the work of production workers. The planned menu indicates the range and quantity of dishes of each item that can be prepared on this enterprise by day of the week or decade. When drawing up a planned menu, the qualifications of cooks, consumer demand, the possibility of supplying raw materials and the seasonality of raw materials, and the technical equipment of the enterprise are taken into account.

The second and main step operational planning is drawing up a menu plan. The menu plan is drawn up by the head of production on the eve of the planned day (no later than 15:00) and approved by the director of the enterprise.

It contains the names of dishes, recipe numbers and the number of dishes, indicating the timing of their preparation in separate batches, taking into account consumer demand.

The main factors to be considered when compiling the menu are: the approximate range of products recommended for catering establishments, depending on its type and type of ration provided, the availability of raw materials and its seasonality.

An approximate assortment of dishes (assortment minimum) is a certain number of cold dishes, hot dishes, drinks typical for various catering establishments (restaurants, canteens, cafes, etc.).

An approximate range of manufactured and sold products for canteens is given in Table. 3.

GOST R 50762-2007 “Catering services. Classification of public catering establishments" [ Electronic resource] // http://www.gostbaza.ru/?gost=44234.

Avetisova A.O. Structural changes in the restaurant business market / Monograph. - Donetsk: DonDUET, 2013. - S. 113-141.

Agranovsky E.D., Anosova M.M., Lifanova R.F. "Organization of production at public catering enterprises". - M.: Economics. 2009. - 350 p.

Alyonushkin D. Fast food: the time of new formats / D. Alyonushkin // Catering business. - 2013. - No. 6. - P.14-15.

Andrushkiv B., Kirich N. How to improve the work of the service sector // Economics, 2012. - No. 6. - P. 82-87.

Akhmedov H.A. Marketing of restaurant services / H.A. Akhmedov, P.B. Karpushenko // Marketing in Russia and abroad. - 2014. - No. 1. - P.41-51.

Bogusheva V.I. Organization of customer service in restaurants and bars. - M., 2014. - 268 p.

Bogusheva V.I. Organization of production and service at public catering enterprises / V.I. Bogushev. - R / n-D: Phoenix, 2012. - 253 p.

Varakuta S.A. Product quality management: Textbook. -M.: INFRA-M, 2014. - 352 p.

Volkova I. A small digression into the restaurant business / I. Volkova, G. Mumrikova // Modern trade. - 2013. - No. 11. - P.39-43.

Voronov A.A., Drugashov D.N. Prospects for the development of the food industry in Russia in the XXI century // food industry, 2013. - No. 5. - S. 47-52.

Goldovskaya M. Restaurant business: moving towards success / M. Goldovskaya // Restaurant business. - 2012. - No. 9. - P.19-21.

Gukkaev V.B. Realization of services by public catering enterprises // Accounting and taxes in trade and public catering, 2013. No. 10. - P. 18-21.

Dubtsov, G. Bakery in catering. Good business advice // Nutrition and society. - 2007. - No. 6. - S. 8-10.

Efimova O.P., Efimova N.M. Economics of hotels and restaurants. - M.: Economics, 2012. - 410 p.

Efimova O.P. Economics of catering. - M.: New title, 2014. - 301 p.

Ivannikova, E.I. Bar business / E.I. Ivannikova, T.V. Ivannikova, G.V. Semenov. - M.: Ed. Center "Academy", Mastery, 2002. - 352 p.

Ivanov A.A., Myasnikova V.V., Public catering in Russia. Current state. Hygienic problems / Ed. Doctor of Medical Sciences, Professor Belyaeva E.N. - M. - FTSGSEN. 2014. - 124 p.

Kabushkin, N.I. Management of hotels and restaurants / N.I. Kabushkin, G.A. Bondarenko: tutorial. - Minsk: New knowledge, 2001. - 216 p.

Kalashnikova S.A. Technology for self-assessment of the quality of services at public catering enterprises // Russian Entrepreneurship, November 2012, issue 1.

Kaplin D. Restaurant business remains a profitable investment area / D. Kaplin, N. Trofimov // Restaurant business. - 2010. - No. 3. - P.18-22.

Krymskaya, B.A., Balashov V.V. Waiter's Handbook. - M.: Economics, 2010. - 192 p.

Lesnik A. L., Smirnova M. N., Zabaev Yu. V. Management of food and beverage service in the hotel business, IPF "Thaler", 2011. - 158 p.

Ogneva C.B. Certification of catering and trade services / C.B. Ogneva // Partners and competitors. - 2013. - No. 9. - P.4-8.

Otteva I. V. Methods for assessing the quality of public catering services / I. V. Otteva // Restaurant business. - 2013. - No. 7. - P.11-14.

Radchenko L.A. Economics of catering. - R / na-D: Phoenix, 2012. - 340 p.

Radchenko L.A. Organization of production at public catering enterprises / L.A. Radchenko. - R / na-D .: Phoenix, 2014. - 320 p.

Samoilov I.V. Catering company. Holding solemn events: registration, payment, accounting operations. // Accounting and taxes in trade and public catering. - 2014. No. 10. - S. 24-27.

Solovieva V.P. Public catering is not only restaurants / V.P. Solovieva // Shop. Restaurant. Hotel. - 2013. - No. 2. - S.28-33.

Topolnik V.G., Ratushny A.S. On the issue of assessing the quality of service in catering establishments. - M.: Daugas, 2013. - 112 p.