Material flows in logistics parameters types classification. flow in logistics. Material, information, financial and other types of flows. Classification of material flows according to physical and chemical properties

Material flow (MF) is called physical movement material resources, understood as the process of their movement on the way from the manufacturer to the consumer and within the enterprise - the consumer of these resources.

The concept of material flow is key in logistics. Material flows are formed as a result of transportation, storage and other material operations with raw materials, semi-finished products and finished products - starting from the primary source of raw materials and up to final consumption.

Material flows can flow between different enterprises or within one enterprise.

From material resources, a group called "materials" is often distinguished. It is divided into two subgroups:

basic materials - materials from which, in the course of their production processing, the material basis for the manufacture of products is formed;

auxiliary materials - materials that are absent in the material part of the finished product, they are included only in its monetary value, since they are spent in production.

Materials make up the bulk of every society's resources. Until recently, all developments in the field of supply and marketing were carried out according to them, but since the second half of the 80s, the concept of "material flow" has become widely used in world science, which has replaced the former term "material resources". But these two concepts are not identical and are not synonymous. Material resources do not always turn into a material flow, they become such only when special conditions, they cease to be a material flow when these conditions are eliminated.

There are several conditions under which material resources turn into a material flow:

specificity of the name of material resources;

clarity in determining the amount of resources;

an indication of which organization is the supplier of material resources and is responsible for their shipment to the buyer;

determining where the material resources that are transferred and subject to movement are stored;

an indication of which organization is the recipient of material resources;

knowledge of the place where the transferred resources should be delivered to their recipient;

setting a deadline for moving resources from the storage location at the supplier to the storage location at the recipient.

Thus, the material flow is material resources of certain types, in certain quantities, moved from certain suppliers of these resources to their certain recipients, from one specific place to another at a predetermined time.

If material resources are collected in one place, but do not move, although they are intended to be sent to any addressee, they are not material flows and represent a material stock.

Any material flow is characterized from qualitative and quantitative sides. This requires, first of all, the parameters that determine the composition of the flow by type of material resources.

The specific aspect is often called the nomenclature of the material flow, and the detailing of this nomenclature is called the assortment. The flow nomenclature can have a different degree of consolidation of the groupings of material resources assigned to each of them. The most common of these groups are:

subclass;

subgroup;

When planning material flows, the nomenclature aspect of a material characteristic is usually used, representing it in an enlarged form. Often, accounting for material flows is also built in the same order. The species-group aspect makes it possible to generalize the conclusions and make them understandable to producers and recipients of products, since the very name of a grouping of products often characterizes one of its main features or several properties of this product.

For rational organization the movement of material resources is not enough nomenclature aspect, it is necessary to supplement it with an assortment one, revealing the composition of each nomenclature grouping by position in a specified form. The specification of material resources is a detailed description of their technical characteristics. This characteristic is different for different classes, subclasses, groups, subgroups and types of products. Material flows can be specified in full or in part.

In order to rationally move and store the material flow, it is necessary to specify it completely, according to all the signs on which the choice of the order of cargo movement depends, i.e. correctly described technical specifications of each assortment position of material resources is an important feature of the material flow, without which it is impossible to organize its effective movement. The characteristics of material flows should reflect the quality of material resources in accordance with the requirements of the buyer. The required quality of materials is usually confirmed by the manufacturer in the assortments. But often there are no such certificates, or they do not guarantee quality. Then the buyer of the resources checks their quality himself and includes the resources in the material flow only after their quality is certified by the control. When the nomenclature, assortment and quality of material resources are formed on this basis, the natural-material composition of the material flow is considered certain.

The concept of "material flow composition" is the first part of its characteristics. When it is prepared, the amount of material resources included in the flow is determined. Quantitative characteristics of material resources are usually not one, but two or more.

Depending on the indicators characterizing the assortment, volume, mass, area, dimensions of the material flow, its packaging, container and transport support is selected.

Taking into account their production and transport capabilities, the seller of material resources and the buyer agree on the time for their delivery to the recipient, to the place he needs.

Material flows are very diverse. It is important to consider the following differences:

by nomenclature: they can contain material resources of one nomenclature (class, group, etc.) and several nomenclature groups;

depending on the natural-material composition, material flows are divided into single-assortment and multi-assortment - with two or more different positions of material resources;

according to the degree of readiness: among the material flows, they are designed, planned, formed, created (formed), disbanded, disbanded (dissipated) or liquidated;

at the place in the circulation process: material flows are divided into awaiting shipment, awaiting unloading, unloaded, accepted into the warehouse;

on the basis of continuity: material flows are continuous and discrete;

according to the frequency of arrival or departure: flows are divided into urgent, long-term, hourly, daily, daily, monthly, etc. Large continuous productions are characterized by daily or daily flows, small - monthly and more rare;

according to the duration of stay of material resources in flows: MP is divided into short-term (no more than a day) and long-term (two-week, monthly);

according to differences in mass or volume: material flows are divided into mass, large, medium and small (mass flows are considered to be flows that are moved by a large group of vehicles; large transportations are smaller than mass and less often; small flows include flows that require combination with others - associated material flows );

by differences in mass: material flows are divided into heavy and lightweight;

according to the degree of repetition: material flows are repetitive and one-time, and recurring are divided into frequently recurring and rare;

according to the degree of aggressiveness, fire and explosion hazard of transported materials: flows are divided into fire and explosive, aggressive, non-flammable, non-explosive, non-aggressive;

according to the method of packing: flows are divided into goods in containers, boxes, bags and other types of containers (bulk flows are distinguished into a special group);

according to the consistency of cargo: flows are divided into liquid, bulk, gaseous and solid.

Material flows are divided into intensive and non-intensive. Tense and amplified flows are considered intensive. The material flow becomes tense according to the following features:

- 1) with the complexity of the formation and complication of shipment;

- 2) with the complexity of acquisition;

- 3) due to the need for accelerated transportation of cargo;

- 4) due to difficulties in its acceptance, etc.

Flows are considered non-intensive if they do not lead to stress during their movement.

Material flows are divided into deterministic and stochastic. Deterministic flows have clear indicators of the characteristics of the material composition. There are the following parameters of a deterministic flow: natural-material composition; volume (quantity); seller and place of dispatch; buyer and place of delivery; shipment time. If one of these parameters is unknown, the flow is not deterministic, they are considered indeterminate or stochastic.

Material flows are distinguished by the rhythm of dispatches. Rhythmic flows are those that repeat periodically. Streams shipped at different intervals and at different time intervals are classified as aperiodic. The main sign of rhythm is the constancy of the frequency of shipment.

Flows are divided into external and internal. External material flows move outside logistics system, i.e. in an environment external to the logistics system in which it is formed or to which it is directed. The internal material flow moves only within one logistics system.

Streams are distinguished by the place of their arrival and departure. Incoming material flows are considered input, shipped - output. Input and output flows are important definitions of material flows, indicating the moment when the flow begins to flow (its exit) from the logistics system and the end of this movement (entrance to the destination logistics system). There are other groupings of material flows.

The concept of logistics flow

Definition 1

The logistics flow is a key object of research in logistics and represents the directed movement of inventory items, as well as financial, informational and other types of resources in a particular economic system.

The main logistical flow is the material flow, it is accompanied or corresponds to information and financial flows, as well as service flows.

All logistics flows in relation to the analyzed logistics system are classified into internal and external. Internal flows circulate within the boundaries of the logistics system, they include, for example, flows of work in progress (material flow), orders and instructions (information flow), wage flows (financial flow).

External streams can be incoming and outgoing. Incoming material flows are due to the purchase of raw materials and materials, outgoing - the sale of finished products. Incoming information flows are, for example, documents accompanying the delivery to the enterprise. An example of an outgoing information flow in logistics is an enterprise requisition for replenishment of stock addressed to a supplier. Incoming financial flows are conditioned by the receipt financial resources to the accounts of the enterprise, outgoing - settlements with suppliers and contractors.

Material flows in logistics

Definition 2

Material flow (MP)- the main type of flow in logistics, represents inventory items (raw materials, materials, work in progress, finished products) that are in motion, to which logistics operations are applied due to physical movement in space and time from the supplier to the consumer.

The material flow parameters are:

- overall and weight parameters,

- density,

- nomenclature,

- range,

- terms of contracts for transportation and sale,

- cost characteristics of the transported goods

- and others.

The forms of existence of the material flow are the cargo flow and the traffic flow. The cargo flow is formed by a set of goods on a vehicle that are in the process of moving from the point of loading to the point of unloading.

Definition 3

Traffic flow - a set of vehicles moving on a given route. The types of transport flow are car flows, wagon flows, container flows, etc. The transport stream, unlike other forms, can be loaded and empty.

Information flows in logistics

Definition 4

Information flow (IP) - flow of messages in speech, paper or electronic forms, designed to implement control functions in the logistics system and due to a specific material flow.

Information flow management is carried out by: changing the flow direction; limiting the transmission rate of the information flow to the corresponding reception rate; limiting the amount of information flow to the value bandwidth separate section of the path or node. Financial flows in logistics

Financial flow (FP)- the flow of financial resources necessary to ensure the movement of the material flow circulating within the logistics system and between the logistics system and the external environment.

The financial flow in logistics is characterized by the following properties:

- orientation of the flow from the source to the consumer of financial resources;

- conditionality by the movement of a specific physical (material, freight or transport) or information flow;

- measurability, that is, the financial flow is measured by specific quantitative indicators.

The main purpose of management financial flows in logistics is to ensure the movement of material flow financial resources in the right time, in necessary volumes, using the most efficient financial sources.

material flow - this is a set of inventory items that are considered at a certain time interval in the process of applying various logistics operations to them

The concept of material flow is key in logistics. Material flows are formed as a result of transportation, storage and other material operations with raw materials, semi-finished products and finished products - from the primary source of raw materials to the end consumer. Material flows can flow between different enterprises or within one enterprise.

In the process of moving from the primary source of raw materials to the final consumer between different enterprises, the qualitative composition of the flows changes. At first, as a rule, homogeneous goods move between the source of raw materials and processing enterprises, and at the end of the chain, the material flow represents various ready-to-eat products.

Within enterprises, material flows pass between trains, workshops, sites and workplaces in the form of raw materials, materials, components at the stage of production support, at the stage of production - in the form of semi-finished products and work in progress, at the stage of marketing - in the form of finished products. The material flow that is considered at a certain point in time is called material stock.

The main quantitative indicators of material flows is tension and power . Material flow tension is the intensity, frequency of movement of material resources, and material flow power are the volumes of products that move per unit of time. Therefore, the flow has the dimension "volume (pieces, tons, etc.) / Unit of time (day, month, year, etc.)". Between these indicators, as a rule, there is an inverse relationship. For example, when supplying an enterprise with large volumes of raw materials or products from abroad over a long distance by sea, the material flow can have a large capacity, but due to the long-term periodicity, tension supply chain may be small. Otherwise, frequent deliveries from the wholesale warehouse to a large number of consumers make the material flow less powerful, but more stressful.

Parameters of material flows are: nomenclature overall, weight, physical and chemical characteristics of the cargo, characteristics of containers, packaging, method of movement, terms of sale, transportation and insurance, financial characteristics and etc.

Given the variety of material resources and operations with them, they classify material flows (Table 4.1).

Table 4.1. Classification of material flows of logistics

|

Classification sign |

Type of material flow |

Characteristic |

|

Relation to the logistics system |

consists of goods related to this enterprise, but move in an environment external to the enterprise |

|

|

interior |

is formed as a result of logistics operations within the enterprise; the starting point of the internal material flow is the composition production stocks, final - warehouse of finished products |

|

|

enters the logistics system from the external environment |

||

|

day off |

leaves the logistics system and enters the external environment for it |

|

|

Direction of travel |

direction of movement from supplier to consumer |

|

|

back |

movement of the material flow in the direction opposite to the original (return of containers, products) |

|

|

Number of cargoes, form a stream |

mass |

arises during the transportation of goods not by a single vehicle, but by a group of them, for example, a railway echelon, a convoy of vehicles, a caravan of ships, etc. |

|

arises during the transportation of goods by several wagons, motor vehicles, ships, etc. |

||

|

intermediate between large and small material flow (cargo in single wagons, cars) |

||

|

occurs when transporting such a quantity of goods, does not allow full use of the carrying capacity of the vehicle and requires, during transportation, to be combined with other goods |

||

|

Specific weight of cargo |

heavy |

in the process of its transportation, the full use of the carrying capacity of vehicles with an unfilled volume is ensured, for example, metals |

|

lightweight |

formed by cargoes, do not allow to fully use the carrying capacity of the transport with the full use of its volume, for example, tobacco products |

|

|

oversized |

products great length, height or width |

|

|

Compatibility |

incompatible |

flows of such goods cannot be jointly transported, for example, goods household chemicals and food |

|

compatible |

can be transported together on the same vehicle |

|

|

Classification sign |

Type of material flow |

Characteristic |

|

Cargo consistency |

bulk |

bulk cargo, transported without containers in specialized vehicles: open wagons, on platforms, in containers, in vehicles (e.g. grain) |

|

bulk cargo, transported without containers, but can freeze, cake, get rid of, as a rule, these are cargoes of mineral origin (for example, coal, sand, salt) |

||

|

packaged |

cargo in bags, containers, boxes, without containers, can be counted |

|

|

bulk |

is transported in tanks and tankers and requires special technical means for transshipment, storage and other logistics operations |

|

|

Nomenclature |

single-product, multi-product |

|

|

Kind of transport |

road, rail, water, air, pipeline |

|

|

Certainty |

deterministic |

all parameters are fully known |

|

stochastic |

at least one parameter is not specified or is a random variable |

|

|

Rhythm |

continuous |

flows of raw materials and materials in continuous production (technological) processes of a closed cycle, flows of oil products, gas transported by pipelines, etc. |

|

discrete |

periodic deliveries |

|

|

blitz stream |

one-time supply |

|

“Marketers say WHAT? to do, and the logistics HOW? do".

The success of any company or firm depends on how efficiently the food and material base is managed. Business always requires a competent and balanced approach and a miscalculation of the situation in advance. This is where logistics comes to the rescue, allowing the company to increase profits and make goods and services competitive by making optimal use of material transport systems.

Flows in logistics are a directed movement in space of a product (materials, raw materials, finance, information, etc.) for a certain time. There are such categories of flows in logistics: material, financial, information and services.

Material flow in logistics

The greatest value in logistics is occupied by the material flow. It is material resources, work in progress and finished products that are in motion. In relation to them, logistics operations are carried out that are associated with movement in space and time from resource providers to consumers.Material flows are classified according to the following criteria:

1. relation to the logistics system:

- external, flowing in the external environment for the company (only goods related to this enterprise);

- internal - operations with cargo within the enterprise;

- input - material flow entering the system from the external environment;

- output - a material flow that goes into external environment from the logistics system;

- one-way streams;

- multi-assortment streams;

- mass material flows (for example, transportation of goods by rail or several dozen wagons);

- large material flows (several cars or wagons);

- small material flows (goods that do not fully use the carrying capacity of the vehicle and require to be combined with other goods during transportation, that is, goods transported by single cars or wagons);

- heavy (maximum use of transport capacity);

- lightweight (do not fully use the carrying capacity of transport);

- bulk;

- bulk;

- packaged;

- liquid cargoes;

- compatible;

- incompatible.

Financial flows in logistics

Financial logistics flows are responsible for the successful functioning of the logistics system and affect other types of flows. Thanks to the financial flow, a certain amount of tangible and intangible values is moved. They also accompany the movement of fixed and working capital.Classification of financial logistics flows:

1. purpose:

- financial flows that determine the process of purchasing goods;

- investment flows;

- financial flows associated with material costs and the results obtained in the production process of the enterprise;

- financial flows for the reproduction of labor force;

- cash flows that reflect the movement of cash financial resources;

- information and financial flows, which are due to the movement of non-cash financial resources;

- horizontal financial flows, reflecting the movement of funds between partners;

- vertical flows of finance, which characterize the movement of finance between divisions of the company.

Information flows in logistics

Information logistics flows flow along with material and financial flows, but at the same time they can both lag behind and ahead of the movement of material resources. Information flows are documentary or speech appeals or messages that serve to control or accompany material flows.There are such types of information logistics flows:

1. according to the type of systems associated with the flow:

- horizontal information flow related to only one level of the hierarchy of the logistics system;

- vertical flow moving from the highest level of the system to the bottom;

- external information flow (between the system and the external environment);

- internal (moving inside the system or its element);

- incoming;

- leaving;

- on electronic media;

- on paper;

- managers;

- accounting and analytical;

- normative reference;

- auxiliary.

The most important parameters of logistics flows are the point of departure and point of arrival of the flow, its length and trajectory. In this case, such parameters of the movement of flows as: speed, density, time and intensity should be taken into account. Discrete and continuous logistics flows are characterized by a degree of continuity and stability: stable and unstable logistics flows. The nature of production and flow process control methods directly affect the manageability, complexity, and frequency with such flow classifications.

The concept of material flow is key in logistics. Material flows are formed as a result of transportation, storage and other material operations with raw materials, semi-finished products and finished products - from the primary source of raw materials up to the end consumer.

Material flows can flow between different enterprises or within one enterprise.

material flow - it is a product that has a material form, which is in a state of motion, considered in the process of applying logistics operations to it and related to a certain time interval. The material flow is not on the time interval, but at a given point in time goes into the inventory.

The dimension of the material flow is a fraction, in the numerator of which the unit of measurement of the cargo is indicated (pieces, tons, etc.), and in the denominator - the unit of measurement of time (day, month, year, etc.).

The material flow is characterized by a certain set of parameters:

Nomenclature, assortment and quantity of products;

Overall characteristics (volume, area, linear dimensions);

Weight characteristics; physical and chemical characteristics of the cargo;

Characteristics of containers (packaging);

Conditions of transportation and insurance;

Financial (cost) characteristics, etc.

Classification of material flows:

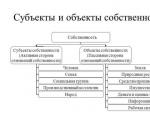

1. distinguish between internal, external, input and output flows.

2.By nomenclature material flows are divided into single-product (single-type) and multi-product (multi-type). The nomenclature is understood as a systematized list of groups, subgroups and positions (types) of products in physical terms for accounting and planning.

3.By assortment material flows are classified into single-assortment and multi-assortment. The product range is the composition and ratio of products of a certain type or name, which differ in grade, type, size, brand, exterior finish and other features. The assortment composition of the flow significantly affects the work with it. For example, the logistics process in a wholesale food market selling meat, fish, vegetables, fruits and groceries will be significantly different from logistics process to a potato storage that works with one item of cargo.)

4.By quantity

- Mass- this is the flow that occurs in the process of transporting goods by a group of vehicles (for example, a train or several dozen wagons, a convoy of vehicles, a caravan of ships, etc.).

- Large- these are the flows of several wagons or cars.

- small- these are the flows of goods, the amount of which does not allow the full use of the carrying capacity of the vehicle, and during transportation it is advisable to combine them with other passing cargo.

- Medium flows occupy an intermediate position between large and small ones. These include flows that form goods arriving in single wagons or cars.

5. By specific gravity the material flows forming the flow of goods are divided into:

- heavyweight, ensuring the full use of the carrying capacity of vehicles. Heavy flows form cargoes in which the mass of one piece exceeds 1 t for water transport and 0.5 t for transport by rail such as metals.

- lightweight, not allowing full use of the carrying capacity of the transport. One ton of light weight flow cargo occupies a volume of more than 2 m 2 (for example, tobacco products).

6.According to the degree of compatibility material flows are divided into compatible and incompatible. This sign is taken into account mainly during the transportation, storage and cargo processing of food products.

7.By physical and chemical properties material flows are divided into:

- Bulk cargo(for example, grain), which are transported without containers. Their main property is flowability. They can be transported in specialized means: bunker-type wagons, open wagons, on platforms, in Containers and in motor vehicles.

- Bulk cargo- as a rule, of mineral origin (salt, coal, ore, sand, etc.). Transported without containers, some may freeze, cake, bake. Also, like the previous group, they have flowability.

- Packaged goods, which have different physical and chemical properties, specific gravity, volume. They can be transported in containers, boxes, bags, as well as without containers: long and oversized cargo.

- liquid cargo, transported in bulk in tanks and tankers. Logistics operations with bulk cargo, such as reloading, storage and others, are carried out using special technical means.

According to the characteristics of the cargo during transportation, material flows can be separately classified according to the transport factor including such characteristics as the mode of transport and the method of transportation, the conditions of transportation, etc.

Each material flow corresponds to a certain information flow, however, the material and information flows are usually displaced relative to each other in time and in direction.

TYPES OF MATERIAL FLOWS

Material flows are defined as goods considered in the process of applying various logistics operations to them. A wide variety of cargo and logistics operations complicates the study and management of material flows. When solving a specific problem, it is necessary to clearly indicate which flows are being studied. When solving some problems, the object of study can be a load considered in the process of applying a large group of operations. For example, when designing a distribution network and determining the number and location of warehouses. When solving other problems - for example, when organizing an intra-warehouse logistics process, each operation is studied in detail.

Material flows are subdivided according to the following main features: relation to the logistics system, the natural-material composition of the flow, the number of goods forming the flow, the specific gravity of the goods forming the flow, the degree of compatibility of goods, consistency cargo.

In relation to the logistics system material flow can be external, internal, input and output.

The external material flow flows in the external environment for the enterprise. This category is not made up of any goods moving outside the enterprise, but only those to which the enterprise is related.

The internal material flow is formed as a result of the implementation of logistics operations with cargo within the logistics system.

The input material flow enters the logistics system from the external environment. In our example, it is determined by the sum of the values of material flows at unloading operations, t/year:

Unloading railway wagons 4870

Unloading containers 2435

unloading road transport 2435

TOTAL input material flow 9740

The output material flow comes from the logistics system to the external environment. For the wholesale base, it can be determined by adding up the material flows that occur during loading operations. various kinds vehicles. In our example, the value of the output material flow is determined as follows, t/year:

Loading vehicles 8279

Container loading 974

Loading rail containers 487

TOTAL output material flow * 9740

* At enterprises wholesale trade the output material flow is called, as a rule, the freight turnover of the base.

If the company maintains stocks at the same level, the input material flow will be equal to the output.

By natural composition material flows are divided into single-assortment and multi-assortment. Such a separation is necessary, the assortment composition of the flow significantly affects the work with it. For example, the logistics process in a wholesale food market selling meat, fish, vegetables, fruits and groceries will be significantly different from the logistics process in a potato store that works with one item of cargo.

By quantity material flows are divided into mass, large, small and medium.

A mass flow is considered to be a flow that occurs in the process of transporting goods not by a single vehicle, but by a group of them, for example, a train or several dozen wagons, a convoy of vehicles, a caravan of ships, etc.

Large flows - several wagons, cars.

Small flows form quantities of goods that do not allow full use of the carrying capacity of the vehicle and require, during transportation, to be combined with other, passing goods.

Medium flows occupy an intermediate position between large and small ones. These include flows that form goods arriving in single wagons or cars.

By specific gravity The material flows that form the flow of goods are divided into heavy and lightweight.

Heavy flows provide full use of the carrying capacity of vehicles, require less storage volume for storage. Heavy flows form cargoes in which the mass of one piece exceeds 1 m(when transported by water) and 0.5 t(when transported by rail). An example of a heavy flow is the metals considered in the process of transportation.

Lightweight flows are represented by loads that do not allow full use of the carrying capacity of the transport. One ton of light weight flow cargo occupies a volume of more than 2 m 3 . For example, tobacco products form lightweight streams during transportation.

According to the degree of compatibility of the goods forming the flow material flows are divided into compatible and incompatible. This sign is taken into account mainly during the transportation, storage and cargo processing of food products.

By cargo consistency material flows are divided into flows of bulk, bulk, packaged and bulk cargo.

Bulk cargoes (for example, grain) are transported without containers. Their main property is flowability. They can be transported in specialized vehicles: bunker-type wagons, open wagons, on platforms, in containers, in motor vehicles.

Bulk cargoes (salt, coal, ore, sand, etc.) are usually of mineral origin. Transported without containers, some may freeze, cake, bake. Just like the previous group, they have flowability.

Packaged - piece cargoes have a variety of physical and chemical properties, specific gravity, volume. It can be cargo in containers, boxes, bags, bulk cargo, long and oversized cargo.

Bulk cargo - cargo carried in bulk in tanks and tankers. Logistics operations with liquid cargoes, for example, reloading, storage and others, are carried out with the help of special technical means.

Schematically, the classification of material flows is shown in fig. fourteen.

Lecture - Logistics service (LS)

1. The concept, principles and tasks of drugs

2.Classification of logistics service

Logistics service is understood as a set of intangible logistics operations that ensure maximum satisfaction of consumer demand in the process of managing material and information flows, in the most cost-effective way. In other words, the logistics service is the management of service flows (Table 7.1.). The logistics service is provided either by the supplier himself or by a forwarding company specializing in the field of logistics services.

Basic principles of logistics service:

- maximum compliance with the requirements of consumers to the nature of the consumed products;

- inseparable connection between service and marketing;

- flexibility of the service, its focus on taking into account changing market requirements.

Table 7.1

Mapping Logistics Operations Management to Material and Service Flows