Companies engaged in production drilling for oil. Geoecological problems during exploration and production drilling for oil and gas. Problems during oil drilling

Drilling volumes in Russia have fully recovered after the crisis of 2014–2015, when lower oil prices and sanctions led to a reduction in investment in the domestic oil industry. At the same time, drilling is becoming more technologically complex and expensive, but experts believe that the current peak in drilling volumes will not last long. On trends in the Russian drilling services market in the review of "Siberian Oil" The article uses materials from a study of the service market in oil industry provided by Techart. .

Ups and downs

After the crisis of 2009 in 2010-2013. in Russia, there was a dynamic increase in the volume of penetration in drilling. During this period, production directional drilling was most actively used. The increase in footage in production drilling over this period amounted to 26.1%, and in exploration drilling - 14.9%.

In 2014, the situation changed: oil prices fell, Russia found itself under sanctions from the EU and the USA, as a result of which investment activity decreased, and drilling volumes again decreased. However, this figure was also affected by another factor: the growth of horizontal drilling, which makes it possible to obtain a higher well flow rate compared to directional drilling. The scope of work in this area from 2008 to 2015. increased by 4.3 times. According to Techart, the share of horizontal drilling in total volume production drilling in 2016 amounted to 33.5% (8.3 million m).

As a result, the drop in total penetration in 2014 was 4.1% compared to 2013. At the same time, exploratory drilling, on the contrary, increased by 21.6%. A year later, the picture changed to the opposite: development drilling won back the fall of 2014, while exploration drilling, on the contrary, decreased. 2016 was characterized by an increase in both development and exploration drilling. According to the results of 2016, the meterage in production drilling amounted to 24.8 million meters (+14.5%), in exploration drilling - 910.0 thousand meters (+6.1%).

In monetary terms, however, the changes in the market looked different. Due to the complication of production conditions, the depletion of traditional fields, in recent years, the demand for such technological services as sidetracking and horizontal drilling has been growing, the average well depth and, accordingly, the volume of investments per meter of penetration have increased.

The structure of the Russian service market in the oil and gas industry

by type of service in 2016, % of the total volume in value termsInfographic: Daria Gashek

The growth of work in new regions with more difficult conditions (when developing new fields in Eastern Siberia, the Timan-Pechora region, etc.) also necessitates higher costs. Lack of infrastructure in the regions and complex natural conditions require the availability of specialized machinery and equipment, which leads to an increase in prices and an increase in the average cost of a well.

According to the CDU of the Fuel and Energy Complex, in 2016 the total volume of investments in production and exploration drilling for all companies producing oil in Russia amounted to 673.5 billion rubles. (11.1 billion dollars). The increase in investment in production drilling compared to 2015 is estimated at 19.4%. Investment in exploratory drilling increased to 9%.

Share of horizontal drilling in Russia

in 2011–2016,

% of total production drilling

Compound Annual Growth Rate (CAGR) of investment in drilling in 2011–2016 amounted to 13.4%. However, due to changes in exchange rates average over the same period in dollar terms showed a negative trend (-1.9%).

In 2016, the average cost per meter drilled in development drilling, calculated as the ratio of investment to total drilling, increased by 4.2% (in ruble terms). The same trend was observed in exploration drilling. The average cost of penetration showed continuous growth during 2011-2016. and in 2016 it reached the level of 57.9 thousand rubles/m for production drilling and 25 thousand rubles/m for exploration drilling.

Major Players

All oilfield service companies currently represented on the Russian market are conventionally divided by analysts into three groups.

The first includes service divisions within VIOCs: NK Rosneft, service divisions of Surgutneftegaz, Bashneft, Slavneft, etc. It should be noted that if in 2009–2013 service divisions were actively withdrawn from VIOCs, the current trend, on the contrary, was the development by oil and gas companies of their own or affiliated service.

Dynamics of drilling volumes in the Russian Federation

in 2011–2016, %

Source: Tekart based on data from the CDU TEK

Source: Tekart based on data from the CDU TEK

The second group is foreign service companies: Schlumberger, Weatherford (in August 2014, Russian and Venezuelan oilfield services assets were bought by Rosneft), Baker Hughes, as well as a number of second-tier companies (KCA Deutag, Nabors Drilling, Eriell and others).

The third group consists of large independent Russian companies whose turnover exceeds $100 million. They arose as a result of the acquisition of oilfield services divisions of oil producing companies or as a result of the merger of smaller service companies. These include BC Eurasia, Siberian Service Company, Gazprom Drilling (sold in 2011 to the structures of A. Rotenberg).

Average cost of penetration in drilling

in 2011–2016, thousand rubles

Source: Tekart based on data from the CDU TEK

Source: Tekart based on data from the CDU TEK

Currently, the leadership in the Russian drilling market in the oil and gas industry remains with large independent companies and structural divisions VINK. At the end of 2016, the TOP-3 market participants in terms of meterage in drilling (in descending order) included EDC (BK Eurasia and SGK-Burenie, previously owned by the Schlumberger group), service divisions of OAO NK Surgutneftegaz and "RN-drilling". In total, these three companies accounted for about 49% of drilling.

Experts assess the technological level of independent Russian service companies as “average”. So far, in comparison with the generally recognized leaders of the world market, they can offer standard services with an optimal price / quality ratio.

The service structures of VIOCs, in terms of technological capabilities, are also at an average level. As a rule, they have the closest ties with scientific branch institutes and have a number of unique patents. Their additional advantage is a large margin of safety and access to the funds of the parent company to finance the purchase of expensive fixed assets.

Foreign service companies, leaders in the global service industry, were the main technology suppliers in the Russian Federation in the early 2000s. Currently, such players as Schlumberger and Halliburton account for about 14% of the Russian service market in the oil and gas industry in monetary terms. However, they are not represented among the largest participants in the drilling services market.

Main competitive advantage major foreign companies - Newest technologies service. Foreign companies were among the first in Russia to start performing complex hydraulic fracturing operations, taking cementing services, drilling fluid preparation and other drilling support services to a new level, using coiled tubing technology for the first time, and offering modern software products.

Their main disadvantage is the high cost of services. It is for this reason that there is currently a decrease in the activity of foreign market participants in Russia. Practice shows that for simple drilling, Russian oil companies prefer to turn to domestic contractors. They use the services of foreign companies mainly in the implementation of complex projects - technologies and competencies in the field of integrated project management are in demand here.

It should be noted that for the world leaders in oilfield services in 2015–2016. after the record results of 2014, they were also unsuccessful on the scale of the global market. The annual turnover of Schlumberger, Halliburton, Baker Hughes and Weatherford decreased by 50-60% to the level of 2010.

Drilling in trend

Russian drilling companies are not public and do not publish information about their fleets, so it is rather difficult to estimate their capacity. The Russian fleet of drilling rigs (DR) of all classes of carrying capacity, according to various estimates, is in the range from 1000 to 1900 units. At the same time, the fleet of operating equipment in 2016 amounted to about 900 drilling rigs, Techart analysts believe.

In terms of the equipment used, each of the groups of companies has its own characteristics of consumption of drilling rigs. Service departments of VIOCs, relying on the authority of the parent company and, as a rule, relatively high volumes of investment programs, often independently dictate the requirements for purchased units. For them, manufacturers are developing new modifications. Foreign contractors prefer to work with European and American equipment suppliers. Independent companies give priority to one or another supplier based on specific needs, ease of purchase and operation of equipment.

Alexey Cherepanov,

Head of Operational Efficiency Programs for Gazprom Neft’s Own Oilfield Services:

Given the introduction of new technologies for the use of big data, which penetrate almost all areas of human activity, drilling efficiency will increase, due to which the profitability threshold for many fields will significantly decrease. With increasing drilling efficiency, as happened in the US during the shale revolution, the relationship between penetration and the number of drilling rigs will change or even disappear in an explicit form. In Russia, the process of transition to high-tech drilling has already begun, therefore, in the absence of general economic shocks, we should expect at least a quantitative change in functional relationships and trends in the next few years.

If in the early 2000s, drilling rigs of foreign production were practically not supplied to Russia, then starting from 2006, imported products gradually gained a foothold in the Russian market. First of all, priority was given to European and American plants (Bentec, Drillmec, National Oil Well Varco, etc.).

However, the demand for drilling equipment in 2006–2008 was active around the world, which led to a significant level of utilization of all major global manufacturers, which took advantage of Chinese companies, which had a significant amount of unloaded capacity.

As a result, already in 2008, the share of Chinese drilling rigs, according to Techart, accounted for more than 60% of the Russian market in physical terms.

In 2011 and 2012 fundamental changes have taken place in the market: the share of imports has decreased. This was due to both the restoration of production at the Uralmash plant and the introduction of an import duty from 2012: 10%, but not less than 2.5 euros / kg. As a result, prices for Chinese drilling rigs soared by 30-40%.

Over the past four years, a rather stable ratio of domestic and foreign (primarily Chinese) products has been observed in the structure of purchases. In the first place is Russian technology (from 46% to 61%). It is followed by equipment imported from China (up to 39%). For 2015–2016 4 American-made units were imported to Russia.

At the moment, the main Russian players capable of producing demanded rigs with a payload capacity of 225–320 tons can manufacture up to 76 rigs per year, with 40 of them accounted for by the Uralmash plant.

Forecast for the future

The prospects for the drilling and related services market are largely related to the development of the service market in the oil and gas industry as a whole.

Despite the decline in oil prices, the drilling market is still attractive to investors. This is due to the need to maintain the current level of production and development of new fields.

Contrary to previous years' expectations, drilling peaked in 2016, according to Techart. In 2017, according to preliminary estimates, there will be a slight increase in the increase in penetration, since the implementation of projects in the Bolshekhetskaya depression (YaNAO) and the Yurubcheno-Tokhomskaya zone (Eastern Siberia) is scheduled for this year. Soon major projects for the development of fields with large volumes of drilling is not planned, therefore, in 2018–2020. the penetration rate is expected to fall to the level of 2016.

In addition to a slight increase in meterage in drilling, outpacing market growth in value terms is expected. This is due to the fact that maintaining production at existing fields involves significant difficulties, and oil companies are moving to the development of new fields in regions such as Eastern Siberia and the Timan-Pechora region, where higher costs are needed.

Drilling Market is a key driving force behind the Russian oilfield services market. Drilling accounts for more than 30% of the total oilfield services market (in monetary terms). Together with drilling services (including horizontal drilling support) and other services used in well construction, this share exceeds 50%.

During 2016, new trends emerged in the drilling market, which significantly affect the prospects for market development and are of fundamental importance for the adoption strategic decisions market participants.

. In 2016, Russia achieved historical maximum oil production in the amount of 547.5 million tons. Active growth in oil production was primarily due to an increase in meterage in drilling - by 23.2% in 2015-2016. The growth in production over the same two years amounted to 3.8%.

In accordance with the agreement on limiting oil production dated December 10, 2016, Russia undertook to reduce production from the level of October 2016 by 300 thousand barrels per day, or by 2.7%. Expected that production in 2017 will decrease by about 0.5% compared to 2016, and in the subsequent period, production will show moderate growth and reach the level of 570 million tons in 2025.

In 2017, despite the limitation of oil production, the drilling market expects increase in drilling volumes by 8-10% from the level of 2016. This is due to the need to maintain production at old, depleting fields.

In the medium term, drilling will mainly focus on maintaining production levels. Starting from 2018, there will be trend associated with moderate growth of the drilling market in physical terms and outstripping growth in monetary terms.

The share of horizontal drilling in production will continue to increase: from 11% in 2010, it has grown up to 36% in 2016, and by 2021 it will reach 44-46%.

In exploration drilling, the decrease in volumes in 2015 was replaced by a 3% increase in 2016. In the period up to 2026, it is predicted comparable volumes of exploration drilling due to the growing importance of additional exploration in mature fields.

Open market share in drilling continues to decrease: in 2016 it amounted to 44% with the prospect of further reduction due to market consolidation by Rosneft.

As a consequence of key market trends, significant increase in competition between contractors, as well as increased price pressure on them from customer companies.

The analytical report aims to provide expert support for making strategic and operational decisions to a wide range of market participants, based on the following key elements of the study:

Grade key factors and development trends, including both general for the oil and gas industry of the Russian Federation, and specific for the drilling market and its key segments.

Market size forecast for the period up to 2026 for production (separately horizontal) and exploration drilling. The forecast is formed in the context of the main regions of oil production and taking into account the peculiarities of drilling in each of them.

Customer analysis and competitive environment contractors, including an assessment of the rig fleet and scope of work.

Report contains a basis for assessing the potential of the entire range of drilling-related service and equipment segments, including drilling services, horizontal drilling support, primary cementing, well completion, and others.

Around sources for the formation of the report were: RPI knowledge base, company data, industry statistics, assessments of industry experts.

« Russian market drilling oil wells» Designed for the following industry audience:

Oil and gas producing companies

Oilfield service companies

Manufacturers and suppliers of oil and gas equipment

Banks and investment companies

Consulting companies

"Russian Market of Oil Drilling" is the first of a series of reports on the main segments of the Russian oilfield services market. The reports analyze the current state and development prospects until 2025 in the following segments:

1. Support for directional drilling(69,500 rubles)

2. Sidetracking (69,500 rubles)

3. Well workover (69,500 rubles)

4. Hydraulic fracturing (69,500 rubles)

5. Seismic exploration (69,500 rubles)

6. Coiled tubing(64,500 rubles)

1. Introduction

2 Main findings of the study

3 Oil and gas condensate production in Russia in 2006-2016 and production forecast for the period up to 2026

3.1 Production of oil and gas condensate in Russia in 2006-2016 by companies

3.2 Production of oil and gas condensate in Russia in 2006-2016 by regions of oil production

3.3 Forecast of annual oil production in Russia for the period 2016-2026

4 Volume of the Russian oilfield services market in monetary terms

4.1 Methodology for calculating the size of the oilfield services market

4.2 Size of the oilfield services market in 2005-2016

4.3 Forecast of the volume of the oilfield services market for 2017-2026

5 Current state of the drilling market

5.1 Dynamics of meterage in drilling in 2001-2016

5.2 Dynamics of production drilling in 2006-2016

5.3 Dynamics of exploration drilling in 2006-2016

5.4 Volume of the drilling market in monetary terms in 2006-2016

5.5 Main production trends in the drilling market

5.5.1 Development of horizontal drilling

5.5.2 Change in capital costs in production drilling

5.5.3 Effects of measures to increase production levels

5.6 Key Technology Trends in the Drilling Market

5.7 Current management challenges and trends in the drilling market

5.7.1 Well Construction Management Issues

5.7.2 Formation of the estimated cost of well construction

5.7.3 Development of time standards

5.7.4 Risk management of well construction projects

6 Forecast of the dynamics of drilling volumes for 2016-2026

6.1 Forecast methodology

6.2 Production drilling forecast for 2017-2026

6.3 Horizontal drilling forecast for 2017-2026

6.4 Forecast of exploration drilling volumes for 2017-2026

6.5 Forecast of drilling market volumes in monetary terms for 2017-2026

7 Major customers in the drilling market

8 Analysis of the competitive environment in the drilling contractor market

8.1 Drilling market in Russia by drilling contractors

8.2 Production capacity of major drilling contractors

8.3 Activities of drilling contractors by region

8.4 Major M&A transactions in the drilling contractor market in 2016

9 Profiles of main contractors

9.1 Independent drilling contractors

9.1.1 Eurasia Drilling Company Ltd.

9.1.2 OOO Gazprom Burenie

9.1.3 ERIELL

9.1.4 Integra-Bureniye LLC

9.1.5 Catoil-Drilling LLC (Petro Welt Technologies Group of Companies, formerly C.A.T. oil AG)

9.1.6 KCA Deutag

9.1.7 Nabors Drilling

9.1.8 NSH ASIA DRILLING LLC (“Neftserviceholding”)

9.1.9 Group of companies (GC) "Investgeoservis"

9.1.10 CJSC Siberian Service Company (SSC)

9.1.11 TagraS-Holding LLC (MC Tatburneft LLC, Burenie LLC)

9.2 Drilling divisions of vertically integrated companies

9.2.1 Drilling subsidiaries of OJSC Rosneft

9.2.2 Drilling unit of NGK Slavneft

9.2.3 Drilling subdivisions of Surgutneftegaz

Graph 3.1. Dynamics of annual volumes of oil and gas condensate production in Russia in 2006-2016 by companies, million tons

Graph 3.2. Distribution of increase in oil and gas condensate production in Russia in 2016 by producers, million tons

Graph 3.3. Share of manufacturing companies in oil and gas condensate production in Russia in 2016, %

Graph 3.4. Dynamics of annual volumes of oil and gas condensate production in Russia in 2006-2016 by regions of oil production, million tons

Chart 3.5. Distribution of growth in oil and gas condensate production in Russia in 2016 by regions of oil production, mmt

Graph 3.6. Forecast of dynamics of annual volumes of oil and gas condensate production in Russia in 2016-2025 by regions of oil production, million tons

Graph 3.7. Forecast of dynamics of annual volumes of oil and gas condensate production in Russia in 2016-2025 by types of deposits, million tons

Graph 4.1. Annual total volumes of the Russian oilfield services market in 2005-2016, billion rubles, % of annual growth

Graph 4.2. Specific shares of segments of the Russian oilfield services market in 2016, % of the total market volume in monetary terms

Graph 4.3. Contribution of segments to the total volume of the Russian oilfield services market in 2016, billion rubles

Graph 4.4. Forecast of Russian oilfield services market in 2017-2026, billion rubles, % annual growth

Graph 4.5. Forecast volumes of segments of the oilfield services market and their specific shares in 2026, billion rubles, %

Graph 4.6. Forecast shares of segments of the Russian oilfield services market in 2017-2026, % of the total market volume in monetary terms

Graph 4.7. Specific shares of segments of the Russian oilfield services market in 2017-2026, % of the total market volume in monetary terms

Graph 5.1. Production and exploration drilling in Russia in 2001-2016, mln. m 30

Chart 5.2. Completed wells in production and exploration drilling in Russia in 2006-2016, units

Graph 5.3. Average depth of one completed well in production and exploration drilling in Russia in 2006-2016, m

Graph 5.4. Influence of an increase in the number of wells and an increase in the depth of wells on the volume of penetration in production and exploration drilling in Russia in 2006-2016, %

Chart 5.5. Production drilling in Russia in 2006-2016 in the context of oil production regions, million m

Graph 5.6. Development drilling in Russia in 2016 in the context of oil production regions, million m

Graph 5.7. Commissioning of wells completed in production drilling in Russia in 2006-2016 by regions of oil production, units

Graph 5.8. Average depth of one completed well in production drilling in Russia in 2015-2016, m

Graph 5.9. Exploration drilling in Russia in 2006-2016 in the context of oil production regions, million m

Chart 5.10. Number of wells completed in exploratory drilling in Russia in 2006-2016 by regions of oil production, units

Chart 5.11. Average depth of one completed well in exploratory drilling in Russia in 2015-2016, m

Chart 5.12. Dynamics of the drilling market in monetary terms in 2006-2016, billion rubles

Graph 5.13. Dynamics of the volume of the drilling market in monetary terms in 2006-2016 by regions of oil production, billion rubles

Graph 5.14. Dynamics of the volume of horizontal and directional drilling in Russia in physical terms in 2006-2016, million m

Chart 5.15. Dynamics of the number of wells completed in horizontal and directional drilling in Russia in 2006-2016, units

Graph 5.16. Average depth of one completed well in production and exploration drilling in Russia in 2006-2016, m

Graph 5.17. Average depth of one horizontal well completed in Russia in 2016, m

Graph 5.18. Average depth of one directional well completed in Russia in 2016, m

Graph 5.19. Dynamics of changes in capital costs per 1 meter of production drilling in Russia in 2006-2016, thousand rubles per m

Chart 5.20. Dynamics of changes in capital costs per 1 m of production drilling for customers in Russia in 2015-2016, thousand rubles per m

Chart 5.21. Effects on the increase in oil production from the commissioning of new wells and geological and technical measures in Russia in 2006-2016, million tons

Graph 6.1. Dynamics of changes in monthly drilling footage in Russia in 2012-2017, million m

Graph 6.2. Forecast of annual meterage in production drilling in Russia for the period 2016-2026, million m

Graph 6.3. Forecast of annual meterage in production drilling in Russia at new fields for the period 2016-2026, mln. m

Chart 6.4. Forecast of the share of drilling at new fields in development drilling in Russia in 2017-2026, %

Chart 6.5. Forecast of annual meterage in horizontal drilling in Russia for the period 2016-2026, million m

Graph 6.6. Forecast of annual meterage in exploratory drilling in Russia for the period 2016-2026, million m

Graph 6.7. Forecast of the volume of the production drilling market by oil production regions in Russia for the period 2016-2026, billion rubles

Graph 6.8. Forecast of the volume of the horizontal drilling market by regions of oil production in Russia for the period 2016-2026, billion rubles

Graph 6.9. Forecast of the volume of the exploratory drilling market by oil production regions in Russia for the period 2016-2026, billion rubles

Drilling is the impact of special equipment on the soil layers, as a result of which a well is formed in the ground, through which valuable resources will be extracted. The process of drilling oil wells is carried out according to different directions works that depend on the location of the soil or rock formation: it can be horizontal, vertical or inclined.

As a result of work, a cylindrical void is formed in the ground in the form of a straight shaft, or well. Its diameter may vary depending on the purpose, but it is always less than the length parameter. The beginning of the well is located on the soil surface. The walls are called the trunk, and the bottom of the well is called the bottom.

Key milestones

If medium and light equipment can be used for water wells, then only heavy equipment can be used for oil well drilling. The drilling process can only be carried out with the help of special equipment.

The process itself is divided into the following stages:

- Delivery of equipment to the site where the work will be done.

- The actual drilling of the mine. The process includes several works, one of which is the deepening of the shaft, which occurs with the help of regular flushing and further destruction of the rock.

- So that the wellbore is not destroyed and does not clog it, the rock layers are strengthened. For this purpose, a special column of interconnected pipes is laid in space. The place between the pipe and the rock is fixed with cement mortar: this work is called plugging.

- Last work is development. The last layer of rock is opened on it, a bottomhole zone is formed, and the mine is perforated and fluid is drained.

Site preparation

To organize the process of drilling an oil well, it will also be necessary to carry out preparatory stage. If the development is carried out in the forest area, it is required, in addition to the preparation of the main documentation, to obtain consent to work in the forestry. The preparation of the site itself includes the following steps:

- Cutting down trees in the area.

- The division of the zone into separate parts of the earth.

- Drawing up a work plan.

- Establishment of a settlement to house the labor force.

- Ground preparation for the drilling station.

- Carrying out marking at the place of work.

- Creation of foundations for the installation of tanks in a warehouse with combustible materials.

- Arrangement of warehouses, delivery and debugging of equipment.

After that, it is necessary to start preparing equipment directly for drilling oil wells. This stage includes the following processes:

- Installation and testing of equipment.

- Wiring lines for power supply.

- Installation of bases and auxiliary elements for the tower.

- Installing the tower and lifting to the desired height.

- Debugging of all equipment.

When the oil drilling equipment is ready for operation, it is necessary to obtain a conclusion from a special commission that the equipment is in good condition and ready for work, and the personnel have sufficient knowledge in the field of safety rules in this kind of production. When checking, it is clarified whether lighting devices have the correct design (they must have an explosion-resistant casing), whether lighting with a voltage of 12V is installed along the depth of the mine. Notes regarding the quality of work and safety must be taken into account in advance.

Prior to drilling a well, it is necessary to install a hole, bring in pipes to strengthen the drill shaft, a chisel, small special equipment for auxiliary work, casing pipes, instruments for measuring during drilling, provide water supply and resolve other issues.

The drilling site contains accommodation facilities for workers, technical facilities, a laboratory building for analyzing soil samples and the results obtained, warehouses for inventory and small working tools, as well as medical aid and safety facilities.

Features of drilling an oil well

After installation, the processes of re-equipment of the traveling system begin: in the course of these works, equipment is installed, and small mechanical means are also tested. Installation of the mast opens the process of drilling into the soil; the direction should not diverge from the axial center of the tower.

After the centering is completed, a well is created for the direction: this process means installing a pipe to strengthen the wellbore and pouring the initial part with cement. After setting the direction, the centering between the tower itself and the rotary axes is re-adjusted.

Pit drilling is carried out in the center of the shaft, and in the process, casing is made using pipes. When drilling a pit, a turbodrill is used; to adjust the rotation speed, it is necessary to hold it with a rope, which is fixed on the tower itself, and is physically held by the other part.

A couple of days before the launch of the drilling rig, when the preparatory stage has passed, a conference is held with the participation of members of the administration: technologists, geologists, engineers, drillers. The issues discussed at the conference include the following:

- The scheme of occurrence of layers in an oil field: a layer of clay, a layer of sandstone with water carriers, a layer of oil deposits.

- Design features of the well.

- The composition of the rock at the point of research and development.

- Accounting for possible difficulties and complicating factors that may arise when drilling an oil well in a particular case.

- Consideration and analysis of the map of standards.

- Consideration of issues related to trouble-free wiring.

Documents and equipment: basic requirements

The process of drilling a well for oil can begin only after a number of documents have been issued. These include the following:

- Permission to start the operation of the drilling site.

- Map of standards.

- Journal of drilling fluids.

- Journal of Occupational Safety at Work.

- Accounting for the functioning of diesel engines.

- Watch log.

To the main mechanical equipment and consumables which are used in the process of drilling a well, include the following types:

- Cementing equipment, cement mortar itself.

- Safety equipment.

- Logging mechanisms.

- Technical water.

- Reagents for various purposes.

- Water for drinking.

- Pipes for casing and actual drilling.

- Helicopter pad.

Well types

At the beginning of the process, the diameter of the trunk is up to 90 cm, and by the end it rarely reaches 16.5 cm. In the course of work, the construction of a well is done in several stages:

- The deepening of the day of the well, for which drilling equipment is used: it crushes the rock.

- Removal of debris from the mine.

- Fixing the trunk with pipes and cement.

- Works during which the obtained fault is investigated, productive locations of oil are revealed.

- Descent of depth and its cementing.

Wells can vary in depth and are divided into the following varieties:

- Small (up to 1500 meters).

- Medium (up to 4500 meters).

- Deep (up to 6000 meters).

- Super deep (more than 6000 meters).

Drilling a well involves crushing an entire rock formation with a chisel. The resulting parts are removed by washing with a special solution; the depth of the mine becomes greater when the entire bottomhole area is destroyed.

Problems during oil drilling

During the drilling of wells, a number of technical problems can be encountered that will slow down or make work almost impossible. These include the following events:

- The destruction of the trunk, landslides.

- Departure into the soil of a liquid for washing (removal of parts of the rock).

- Emergency conditions of equipment or mine.

- Drilling errors.

Most often, wall collapses occur due to the fact that the rock has an unstable structure. Signs of collapse are increased pressure, higher viscosity of the fluid that is used for flushing, and an increased number of rock pieces that come to the surface.

Fluid absorption most often occurs if the underlying formation completely takes the solution into itself. Its porous system or high absorbency contributes to this phenomenon.

In the process of drilling a well, a projectile that moves clockwise reaches the bottom hole and rises back. The drilling of the well reaches the bedrock formations, into which a tie-in takes place up to 1.5 meters. To prevent the well from being washed out, a pipe is immersed at the beginning, it also serves as a means of carrying the flushing solution directly into the gutter.

The drill string as well as the spindle can rotate with different speed and frequency; this indicator depends on what types of rocks need to be punched, what diameter of the crown will be formed. The speed is controlled by a regulator that regulates the level of load on the bit used for drilling. In the process of work, the necessary pressure is created, which is exerted on the walls of the face and the cutters of the projectile itself.

Well drilling design

Before starting the process of creating an oil well, a project is drawn up in the form of a drawing, which indicates the following aspects:

- Properties of the discovered rocks (resistance to destruction, hardness, degree of water content).

- The depth of the well, the angle of its inclination.

- The diameter of the shaft at the end: this is important for determining the extent to which the hardness of the rocks influences it.

- Well drilling method.

The design of an oil well must begin with determining the depth, the final diameter of the mine itself, as well as the level of drilling and design features. Geological analysis allows you to resolve these issues, regardless of the type of well.

Drilling methods

The process of creating a well for oil production can be carried out in several ways:

- Shock-rope method.

- Work with the use of rotary mechanisms.

- Drilling a well using a downhole motor.

- Turbine drilling.

- Drilling a well using a screw motor.

- Drilling a well with an electric drill.

The first method is one of the most well-known and proven methods, and in this case the shaft is pierced by chisel strikes, which are produced at regular intervals. Impacts are made through the influence of the weight of the chisel and the weighted rod. The lifting of the equipment is due to the balancer of the drilling equipment.

Work with rotary equipment is based on the rotation of the mechanism with the help of a rotor, which is placed on the wellhead through the drilling pipes, which act as a shaft. Drilling of small wells is carried out by participating in the process of the spindle motor. The rotary drive is connected to a cardan and a winch: such a device allows you to control the speed at which the shafts rotate.

Turbine drilling is performed by transmitting torque to the string from the motor. The same method allows you to transfer the energy of hydraulics. With this method, only one channel of energy supply at the bottomhole level functions.

A turbodrill is a special mechanism that converts hydraulic energy in solution pressure into mechanical energy, which provides rotation.

The process of drilling an oil well consists of lowering and raising the string into the mine, as well as holding it in the air. A column is a prefabricated structure made of pipes that are connected to each other by means of special locks. The main task is to transfer various types of energy to the bit. Thus, a movement is carried out, leading to the deepening and development of the well.

The term "production drilling"

Production drilling - this stage is a continuation of the work on the well that was started during exploration drilling. Development drilling is preceded by the development of the area where it is planned to be carried out, which is associated with the development of exploration drilling. So, in the area where development drilling is planned, all the necessary communications have already been carried out, roads have been built to ensure the process. Sometimes it happens that electricity is not supplied to the site for a number of reasons. Then diesel power plants are used, from which drilling rigs can already work. Drilling production wells differs from exploration drilling precisely in that all production wells are directional, while exploration wells are vertical. For drilling directional or horizontal wells, special navigation systems are used that track the location of the bit. It is installed in the bottom hole assembly and measures parameters by transmitting them to the top using the drilling fluid. Production wells may also include horizontal wells. Their last string can enter the exploited formation at an angle and then take a horizontal direction. Thus, a high degree of contact between the exploited formation and the casing is achieved. As a rule, horizontal wells have a higher flow rate than conventional wells.There is also another difference between production and exploration drilling. It consists in studies that are carried out directly in the wells. So, in exploratory wells, this volume of field geophysical research is very large, and in production wells it is limited only to the necessary minimum. Thus, the costs of studying an exploratory well are much higher than those of a production well.

Drilling rigs are used in production drilling. They may also differ from those used in exploratory drilling.

Since in the sixties there was a very high efficiency of exploration drilling, and a lot of large deposits in the seventies, it was from that moment that all the main efforts were thrown into drilling production wells. For an optimal balance between exploratory and production drilling, the experience of field development, as well as the development period, are taken into account.

The stage of production drilling ends with the process of testing the well, or in other words, its development. The main thing in testing a production well is the perforation process, which is an operation carried out in the well using firing devices to create holes in the casing that are the communication between the reservoir and the well.

Companies with production drilling in their news: TATNEFT , SLAVNEFT , RUSSNEFT ,

Introduction

2.1 Exploration phase

2.2 Well drilling

2.4 Mud

2.5 Offshore drilling

3.2 Well design

Conclusion

Bibliography

Introduction

Oil and natural gas are among the main minerals. Oil production began to grow at a particularly rapid pace after boreholes began to be used to extract it from the bowels of the earth. The growing consumption of oil and gas in industry and the possibility of their rapid and economical extraction from the bowels make these minerals an object of priority exploration.

From the point of view of ecology, oil production, oil refining and gas industry are major environmental pollutants and have a negative chemical and physical impact on all natural components.

The expansion of the mineral resource base and fuel and energy resources is inextricably linked with an increase in the volume of drilling operations for the search and detailed exploration of the most important types of minerals.

Since a further increase in the number of exploratory and production wells, as well as in the volume of mining by an open method, is inextricably linked with the violation of the ecological balance, the protection of the environment and the protection of the subsoil are of great economic importance.

drilling

1. Regulatory framework governing economic activity

The legal protection of nature is a set of legal norms established by the state and legal relations arising as a result of their implementation, aimed at the implementation of measures to preserve the natural environment, rational use of natural resources, and improve the human environment for the benefit of present and future generations.

into the system legal protection The nature of Russia includes four groups of legal measures:

) legal regulation of relations on the use, conservation and renewal of natural resources;

) organization of education and training of personnel, financing and logistics of environmental protection activities;

) state and public control for the fulfillment of the requirements of nature protection;

) legal liability of offenders.

Sources of environmental law are legal acts that contain legal norms governing environmental relations.

The environmental legislation includes Federal Law No. 7-FZ dated January 10, 2002 "On Environmental Protection" and other legislative acts of a comprehensive legal regulation.

The subsystem of natural resource legislation includes: the Land Code of the Russian Federation, the Law of the Russian Federation of February 21, 1992 No. 2395-1 "On Subsoil", the Fundamentals of Forest Legislation of the Russian Federation, the Water Code of the Russian Federation, the Federal Law of April 24, 1995 No. 52-FZ "On wildlife", as well as other legislative and regulations.

The following are some of the documents in the field of regulation of the work of the oil and gas industry:

· PB 08-623-03Safety rules for the exploration and development of oil and gas fields on the continental shelf;

· No. 116-FZ Federal Law "On Industrial Safety of Hazardous Production Facilities";

· Regulations for the preparation of design technological documents for the development of oil and gas oil fields

RD 153-39-007-96(instead of RD 39-0147035-207-86).

This Regulation defines the structure and content of project documents for the commercial development of technological schemes, projects and refined development projects, as well as trial operation projects and technological schemes for pilot development of oil and gas and oil fields, both when using the development methods mastered by practice, and when applying methods to increase oil recovery from reservoirs.

2. Exploration and production drilling for oil and gas. General information

2.1 Exploration phase

Exploration stage is carried out in one stage. The main goal of this stage is to prepare the fields for development. In the process of exploration, deposits, reservoir properties of productive horizons should be outlined. Upon completion of exploration work, industrial reserves are calculated and recommendations are given for putting deposits into development.

Exploration of hydrocarbon deposits - a set of works that allows you to evaluate industrial value deposit identified at the prospecting stage and prepare it for development. Includes drilling of exploratory wells and conducting research necessary to calculate the reserves of the identified deposit and design its development.

In the course of geological exploration, the following parameters are revealed:

geological structure of the deposit;

spatial location, conditions of occurrence, shape, size and structure of deposits;

quantity and quality of minerals;

technological properties of deposits and factors that determine the operating conditions of the deposit

When designing a system for placing exploratory wells, their number, location, drilling order and density of the well grid are determined. The most commonly used grid of wells is uniform over the area of the field. The main indicators of the efficiency of the exploration stage:

the cost of 1 ton of oil and the increase in reserves per 1 m of drilled exploratory wells;

the ratio of the number of productive wells to the total number of wells.

2.2 Well drilling

Among geological studies and works, a large place is occupied by well drilling, their testing, core sampling and its study, oil, gas and water sampling and their study, etc.

Drilling -the process of destroying rocks with the help of special equipment- drilling equipment.

Goals and objectives:

· determination (clarification of tectonics, stratigraphy, lithology, assessment of the productivity of horizons) without additional well construction;

· identification of productive objects, as well as for delineation of already developed oil and gas reservoirs;

· extraction of oil and gas from the bowels of the earth;

· injection of water, gas or steam into reservoirs in order to maintain reservoir pressure or treat the bottomhole zone. These measures are aimed at lengthening the period of the flowing method of oil production or increasing the efficiency of production;

· oil and gas production with simultaneous refinement of the reservoir structure;

· determination of the initial oil and water saturation and residual oil saturation of the formation (and other studies);

· observation of the object of development of the study of the nature of the movement of reservoir fluids and changes in the gas-oil saturation of the reservoir;

· the study of the geological structure of large regions in order to establish the general patterns of occurrence of rocks and to identify the possibility of the formation of oil and gas deposits in these rocks.

Drilling wells for oil and gas, carried out at the stages of regional work, prospecting; exploration, as well as development, is the most time-consuming and costly process. The high costs of drilling wells for oil and gas are due to: the complexity of drilling to great depths, the huge volume of drilling equipment and tools, as well as the various materials that are required to carry out this process, including mud, cement, chemicals, etc. in addition, costs increase due to the provision of environmental protection measures.

2.3 Main problems in drilling wells

The main problems that arise in modern conditions when drilling wells, prospecting and exploration of oil and gas, are as follows.

The need for drilling in many regions to a greater depth, exceeding 4-4.5 km, is associated with the search for hydrocarbons in the unexplored low parts of the sediment section. In this regard, the use of more complex, but reliable well designs is required to ensure the efficiency and safety of work. At the same time, drilling to a depth of more than 4.8 km is associated with significantly higher costs than drilling to a shallower depth.

In recent years, more difficult conditions have arisen for drilling and prospecting for oil and gas. Exploration work on present stage are increasingly moving into regions and areas characterized by complex geographical and geological conditions. First of all, these are hard-to-reach areas, undeveloped and undeveloped, including Western Siberia, the European north, tundra, taiga, permafrost, etc. In addition, drilling and prospecting for oil and gas are carried out in difficult geological conditions, including thick strata of rock salt (for example, in the Caspian Sea), the presence of hydrogen sulfide and other aggressive components in deposits, abnormally high reservoir pressure, etc. These factors create big problems in drilling, prospecting and exploration of oil and gas.

Going out with drilling and searching for hydrocarbons in the waters of the northern and eastern seas washing Russia creates huge problems that are associated both with the complex technology of drilling, prospecting and exploration of oil and gas, and with environmental protection. Access to offshore territories is dictated by the need to increase hydrocarbon reserves, especially since there are prospects there. However, it is much more difficult and expensive than drilling, prospecting and exploration, and the development of oil and gas accumulations on land.

Drilling to great depths (over 4.5 km) and trouble-free well drilling are impossible in many regions. This is due to the backwardness of the drilling base, depreciation of equipment and the lack of effective technologies for drilling wells to great depths. Therefore, there is a problem - in the coming years to modernize the drilling base and master the technology of ultra-deep drilling (ie drilling over 4.5 km - up to 5.6 km and more).

Problems arise when drilling horizontal wells and the behavior of geophysical surveys (GIS) in them. As a rule, the imperfection of drilling equipment leads to failures in the construction of horizontal wells.

Drilling errors are often caused by the lack of accurate information about the current coordinates of the well in relation to geological benchmarks. Such information is needed especially when approaching a reservoir.

Actual problem is the search for traps and the discovery of accumulations of oil and gas of a non-anticlinal type. Many examples from foreign objects indicate that lithological and stratigraphic, as well as lithological-stratigraphic traps can contain a huge amount of oil and gas.

In our country, structural traps are used to a greater extent, in which large accumulations of oil and gas have been found. Almost every oil and gas province (OGP) has a large number of new regional and local uplifts, constituting a potential reserve for the discovery of oil and gas deposits. Oilmen were less interested in non-structural traps, which explains the absence of major discoveries in these conditions, although oil and gas objects of insignificant reserves have been identified in many oil and gas fields.

But there are reserves for a significant increase in oil and gas reserves, especially in the platform areas of the Ural-Volga region, the Caspian Sea, Western Siberia, Eastern Siberia, and others. First of all, reserves can be associated with the slopes of large uplifts (arches, megaswells) and the sides of adjacent depressions and troughs, which are widely developed in the above regions.

The problem is that we do not yet have reliable methods for searching for non-anticlinal traps.

In the field of prospecting and exploration of oil and gas, there are problems associated with increasing the economic efficiency of geological exploration for oil and gas, the solution of which depends on: improving geophysical research methods due to the gradual complication of the geological and geographical conditions for finding new objects; improving the methodology for searching for various types of hydrocarbon accumulations, including non-anticlinal genesis; increasing the role of scientific forecasting in order to provide the most reliable justification for conducting prospecting work for the future.

In addition to the above main problems facing oilmen in the field of drilling, prospecting and exploration of oil and gas accumulations, each specific region and area has its own problems. The further growth of proven oil and gas reserves, as well as the economic development of regions and districts and, consequently, the well-being of people, depend on the solution of these problems.

2.4 Mud

drilling fluid - a complex multicomponent dispersed system of suspension, emulsion and aerated liquids used for flushing wells during drilling. For the preparation of drilling fluids, finely dispersed, plastic clays with a minimum sand content are used, which are capable of forming a viscous suspension that does not settle for a long time with water.

When circulating in the well, the drilling fluid: creates counter pressure to the pore pressure; cleans the bottomhole from cuttings; transports cuttings from the well; transfers hydraulic energy to the downhole motor and bit; prevents screes, collapses, etc.; provides a lubricating and anti-corrosion effect on the drilling tool; cools and lubricates the bit; providing information about the geological section.

The choice of mud formulations for drilling individual intervals of deep wells in complex mining and geological conditions is the most difficult, therefore, the use of universal drilling fluids is very effective, which allows, with minimal adjustments, to provide for various drilling intervals. Minimizing the consumption of materials for the preparation of the solid phase of drilling fluids makes it possible to simplify the problem of their disposal.

The country's drilling organizations are increasingly using drilling fluids with a low solids content (polymer clay, polymer muds, muds with a condensed solid phase, etc.). This makes it possible to reduce the consumption of clays, increase the mechanical speed of drilling, and improve the technical and economic indicators of drilling operations.

Noteworthy is the method of using environmentally friendly drilling fluids based on peat and sapropels, developed at the Tomsk Polytechnic University.

For the preparation of drilling fluid from peat, soda, KSSB, CMC and other non-deficient and environmentally friendly substances are used. The drilling fluid was characterized by stable properties and was easily cleaned from cuttings.

The cost of 1 m of drilling a well using a peat solution for flushing is about 2 times lower compared to clay. If we take into account that additional costs are required for the neutralization and disposal of toxic drilling waste, then economic efficiency the use of peat solutions will be much higher. Peat drilling fluids are suitable for drilling wells in clayey and carbonate rocks, salt deposits, as well as when opening productive formations. In many cases, peat can be replaced by clays and chalk, while solutions are obtained with a low content of the solid phase and an insignificant consumption of alkaline and polymeric reagents and surfactants.

It should be noted that since the concentration of the solid phase of peat muds is low (2-8%), then, accordingly, the consumption of reagents is two to three times less than for the treatment of clay and chalky drilling muds. Based on peat, effective and cheap reagents and modifiers for clay solutions have been obtained.

Distinctive feature peat drilling fluids is their good compatibility with clay, carbonate and mineralized solutions, as well as with all polymer additives. The density of the solution can be adjusted by selecting the appropriate genetic type of sapropel: organic sapropel and peat sapropels make it possible to obtain drilling fluids with a density of 1.01-1.03 g/cm3, siliceous and mixed sapropels 1.04-1.06 g/cm3, carbonate - 1, 07-1.12 g/cm3. If necessary, they can be additionally weighted with chalk and barite.

Peat is a cheap and widespread organogenic raw material and can be used both in its natural form and in the form of lumpy products of numerous peat enterprises. Especially promising is the use of peat instead of clays in hard-to-reach regions of Siberia and the Far North, since the cost of clay powders is $35-40/t, and transportation costs for their delivery to the Tyumen region reach $100/t.

Compositions of drilling fluids based on peat for drilling wells in permafrost rocks, clayey deposits and opening productive formations have been developed. High technological and rheological properties are possessed by polymer peat solutions with a low consumption of macromolecular compounds and surfactants, suitable for drilling wells under conditions of high temperatures and pressures, as well as polymineral aggression. Peat drilling fluids are environmentally friendly, easily cleaned of sludge, after use they can be used for reclamation of disturbed lands both in the form of solutions and unused peat residues formed in wells.

On the basis of peat and sapropels, cement lightweight materials for well casing have been obtained, which have high corrosion resistance to formation waters. In addition, when using them, savings in cement are achieved.

According to the calculations of VNIIKR oil, a reduction in the consumption of materials by only 1% when drilling wells will allow, without additional costs for their production, only in the Minnefteprom to increase the volume of penetration by 200-300 thousand m. The use of peat and sapropels in drilling will make it possible to significantly reduce the cost of purchasing clay powders and chemical reagents. But the main economic effect can be obtained by reducing the environmental burden on environment and reduce the cost of environmental protection measures.

The use of cheap and widespread organogenic raw materials with high adsorption and ion-exchange capacity is also possible for drilling wastewater treatment. Peat and sapropel are widely used to increase the fertility of unproductive soils. All this testifies to the need for a large-scale introduction of peat and sapropel for the neutralization of drilling waste and the reclamation of disturbed lands.

A significant part of the reagents used to control the properties of solutions is, to some extent, harmful to human health. When introduced into the solution and evaporated, they pollute the air, as a result of which their concentration in the air of the working area (the space up to 2 m above the floor or working platform, where there are places for permanent or temporary stay of workers) is limited. The maximum permissible concentrations (MAC) of harmful substances in the air of the working area according to GOST 12.1.005-76 are considered to be concentrations that, during daily (except weekends) work for 8 hours or for other durations, but not more than 41 hours per week, for of the entire working experience cannot cause diseases or deviations in the state of health, detectable modern methods research, in the process of work or long-term life of the present and subsequent generations.

2.5 Offshore drilling

The depletion of onshore oil and gas reserves is gradually increasing and the global energy crisis is aggravating, which leads to the need for more and more extensive development of oil and gas resources of the seabed.

Oil production in the sea is now about 1/3 of the world. Already at the present time, such countries as Norway, Great Britain, the Netherlands, fully satisfy their needs for oil at the expense of offshore fields, and Great Britain also for gas.

Potential oil and gas resources in the waters of the World Ocean exceed their reserves on land by almost three times.

Russia is currently on the verge of industrial development of oil and gas reserves on the continental shelf. It has 22% of the shelf area of the World Ocean, 80% of which are considered promising for hydrocarbon production. About 85% of the reserves of fuel and energy resources are on the shelf of the Arctic seas, 12% are on the shelf of the Far Eastern seas, and the rest is on the shelves of the Caspian, Black, Azov and Baltic seas.

3. Main technogenic objects and their impact on the environment

3.1 Equipment used in well drilling

Well drilling is carried out with the help of drilling rigs, equipment and tools.

Figure 1. Drilling rig

A drilling rig is a set of ground equipment required to perform well drilling operations (Figure 1). The drilling rig includes:

·derrick;

· equipment for mechanization of tripping operations (hoists and winches);

· surface equipment directly used in drilling;

·actuator;

· drilling fluid circulation system;

· accustomed buildings.

The tool used in drilling is divided into main (chisels) and auxiliary (drill pipes, tool joints, centralizers).

Drill pipes are designed to transmit rotation to the bit (in rotary drilling).

3.2 Well design

The upper part of the well is called the mouth, the bottom is called the bottom, the side surface is called the wall, and the space bounded by the wall is the wellbore. The length of the well is the distance from the wellhead to the bottom along the axis of the wellbore, and the depth is the projection of the length onto the vertical axis. Length and depth are numerically equal only for vertical wells. However, they do not coincide for deviated and deviated wells.

Figure 2. Well device

The following rows of casing pipes are lowered into the well (Figure 2):

Direction - to prevent erosion of the mouth.

Conductor - for fixing the upper unstable intervals of the section, isolating horizons with groundwater, installing blowout control equipment at the mouth.

Intermediate casing (one or more) - to prevent possible complications when drilling deeper intervals (when drilling the same type of section of strong rocks, the casing may be absent).

Production casing - for isolating horizons and extracting oil and gas from the formation to the surface. The production string is equipped with elements of string and annular equipment (packers, shoe, check valve, centralizer, thrust ring, etc.).

3.3 Types of offshore drilling rigs

drilling barge- for drilling wells mainly in shallow and protected areas (Figure 3). Scope - intracontinental deposits: estuaries, lakes, swamps, channels and at shallow depths (usually from 2 to 5 meters). Drilling barges are usually non-self-propelled, and therefore not able to work in an open sea situation.

Figure 3. Drilling barge

A self-elevating floating drilling rig is a floating pontoons, in the center of which a drilling rig is installed, and at the corners there are support columns. At the drilling site, the columns sink to the bottom and go deep into the ground, and the platform rises above the water. The depth of water on which the jack-up drilling platform can operate is limited, as a rule, by the length of the supports and does not exceed 150 meters. stability depends on what kind of soil at the bottom of the sea.

Submersible drilling rig.Not a common type of drilling rig.

The submersible installation is a platform with two housings placed on top of each other. In the upper building there are living quarters for the crew. The lower part is filled with air (which ensures buoyancy) when moving, and after arriving at the destination, the air is released from the lower body, and the drilling platform sinks to the bottom.

Advantage - high mobility, however, the depth of drilling operations is small and does not exceed 25 meters.

Semi-submersible platformsused at great depths (more than 1500 m.). Platforms float above the drilling site, held by heavy anchors. The design includes supports that keep the platform buoyant and provide a lot of weight to keep it upright. (when the air is released, the semi-submersible installation sinks only partially, without reaching the seabed and remains afloat).

In the process of drilling operations, the lower casing is filled with water, as a result of which the necessary stability is achieved.

drilling ship

Drilling vessels are self-propelled and therefore do not require towing to the work site. They are designed specifically for drilling wells at great depths (not limited). The drill shaft passes through the entire hull of the vessel, expanding to the bottom. Oil produced and then refined is stored in the tanks of the hull, and subsequently it is loaded into shuttle cargo tankers.

Gravity-type drilling platforms are the most stable, as they have a powerful concrete base resting on the seabed. Drilling columns, storage tanks for mined raw materials and pipelines are built into this base, and a drilling rig is located on top of the base. The seabed at the location of the gravity platforms must be carefully prepared. Even a slight slope of the bottom threatens to turn the drilling rig into the Leaning Tower of Pisa, and the presence of protrusions on the bottom can cause a split in the base.

3.4 Impact of man-made objects on the environment

The modern technology of well casing during drilling is imperfect and does not provide reliable isolation of the formations behind the casing string. For this reason, fluids flow from high-pressure reservoirs to low-pressure reservoirs, i.e. most often from the bottom up. As a result, the quality of the entire hydrosphere deteriorates sharply.

When carrying out geological exploration, exploitation and transportation of oil, land is withdrawn, natural waters and the atmosphere are polluted. All components of the environment in oil-producing areas experience an intense technogenic load, while the level of negative impact is determined by the scale and duration of exploitation of hydrocarbon deposits.

The processes of exploration, drilling, production, preparation, transportation and storage of oil and gas require large volumes of water for technological, transport, household and fire-fighting needs with the simultaneous discharge of the same volumes of highly mineralized wastewater containing chemicals, surfactants and oil products .

Sources of pollution of the territory and water bodies in the oil fields are present to one degree or another in any area technological scheme from wells to oil refinery tanks.

The main environmental pollutants in technological processes oil production are: oil and oil products, sour and hydrogen sulfide-containing gases, mineralized reservoir and waste waters of oil fields and well drilling, drilling sludge, oil and water treatment and chemical reagents used to intensify the processes of oil production, drilling and treatment of oil, gas and water (in the table 1. the main negative impacts of the work on the OS are presented).

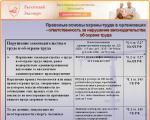

Table 1.

Negative impact on the environment of prospecting, exploration and exploitation of oil fields

Production and technological stagesNatural objectsTerrestrial surfaceAquatic environmentAtmospheric airSearch and exploration Disturbance and pollution of soil and vegetation cover. Alienation of land for the construction of drilling rigs and placement of temporary settlements. Activation of exogenous geological processes. Decreased bioproductivity of ecosystems Pollution of surface and ground waters with flushing liquid, salinization of surface water bodies during self-outflow of brines discovered by structural prospecting and exploration wells Accidental releases of oil and gas in the process of drilling and development of wells. Gas and dust pollution during construction of roads and industrial sites. Emission of exhaust gases by vehicles and engines of drilling rigs Primary processing and transportation Diversion of land for waste storage. Violation environmental situation during the construction and operation of main oil pipelines Leakage of oil products and chemical reagents from tanks and dosing units. Pollution of surface and underground waters with fuels and lubricants (fuel and lubricants), household and technical waste. Spraying and bottling of oil and oil products. Losses during evaporation of light fractions of oil during storage in tanks and during loading and unloading operations

The well construction technology used in our time causes both man-made disturbances on the surface of the earth, and changes in physico-chemical conditions at depth when opening reservoir layers during drilling. Environmental pollutants during drilling and well equipment are numerous chemical reagents used to prepare drilling fluids. To date, not all reagents that are part of drilling fluids have established MPCs and limiting hazard indicators.

Oil and oil products significantly pollute the environment, which can come to the surface not only as components of drilling fluids, but also when using fuels and lubricants, when testing wells or as a result of an accident.

During the construction of drilling rigs, atmospheric pollution is mainly limited to emissions of exhaust gases from engines Vehicle.

The operation of diesel installations during the year at one drilling rig ensures the release into the atmosphere of up to 2 tons of hydrocarbons and soot, more than 30 tons of nitrogen oxide, 8 tons of carbon monoxide, 5 tons of sulfur dioxide.

During the drilling of a well, drilling fluids have a negative impact on the soil layer, surface and ground waters, the flow rate of which per one object can reach 30 m3/day. In addition, when drilling wells, it is possible to use oil products in the amount of up to 1 thousand tons per year.

During the testing of the well, hydrocarbon pollution prevails, and at the stage of dismantling the drilling rig, the territory is contaminated due to the used technical materials and non-repairable equipment.

The composition of flushing fluids includes a number of chemical ingredients that have toxic properties (ammonium, phenols, cyano groups, lead, barium, polyacrylamide, etc.) Especially severe environmental consequences are caused by the discharge of flushing fluids special purpose, for example, solar-based. The presence of organic reagents contributes to the formation of suspensions and colloidal systems in wastewater.

Sources of pollution during well drilling can be divided into permanent and temporary (Figure 4).

Figure 4—Classification of pollution sources during well drilling

3.5 Environmental issues in well drilling

So below are the main environmental problems arising during drilling of wells:

· the ability to cause deep transformations of natural objects of the earth's crust at great depths - up to 10-12 thousand meters. Large-scale and very significant impacts on reservoirs (oil, gas, aquifers, etc.) are carried out in the process of oil and gas production. Thus, intensive oil extraction on a large scale from highly porous sandy reservoirs leads to a significant decrease in reservoir pressure, i.e. formation fluid pressure - oil, gas, water. Thus, the equilibrium of the lithosphere is disturbed, i.e. the geological environment is disturbed;

· In order to maintain reservoir pressure, the injection of surface water and various mixtures into reservoirs is widely used, which leads to a complete change in the physical and chemical situation in them. Do not forget about the amount of water pumped into the reservoirs;

· In emergency situations during open spouting, fluids can pour out onto the surface and directly pollute the environment - soils, lands, waters, atmosphere, vegetation;

· In the process of drilling wells, even without violating the technology, drilling fluids enter the absorbing horizons, as well as the penetration of the fluid filtrate into the near-wellbore space;

· Highly toxic gases, such as, for example, hydrogen sulfide, can come from the well and stand out from the solution; flares that burn unused associated petroleum gas are environmentally hazardous;

· it is necessary to withdraw the corresponding plots of land from agricultural, forestry or other use. Oil and gas production facilities (wells, oil collection points, etc.) occupy relatively small areas in comparison, for example, with coal pits that occupy very large areas (both the quarry itself and overburden dumps);

· The use of a huge number of vehicles, especially auto-tractor equipment for the preparation of drilling and drilling operations. All this equipment - automobile, tractor, river and sea vessels, aircraft engineering, internal combustion engines in the drives of drilling rigs, etc. in one way or another they pollute the environment: the atmosphere - with exhaust gases, water and soil - with petroleum products (diesel fuel and oils), mechanically (soils are pressed).

4. Measures to reduce the negative impact

4.1 Stage of preparatory work for the construction of exploration wells

At the first stage of preparatory work for the construction of exploration wells, there is a need for a rational choice of land for the construction of drilling sites. Provision of land allotments for the construction of wells for temporary use is carried out for the entire period of mineral exploration, after which they must be returned to the user of the land in a condition suitable for agricultural use. To ensure effective environmental protection and reliable protection of subsoil, it is necessary to have the following data: description of the complex geological structure, rationale for the choice necessary equipment and materials, estimated volumes of drilling fluids and generated drilling wastes, selection and provision of progressive systems for drilling in productive formations, reduction of material losses during exploration, interpretation of economic and environmental indicators of drilling operations.

Special attention should be removed from the adoption of measures for possible complications and accidents when drilling wells, the preservation of land from pollution, their neutralization and full restoration to their original state, suitable for further use.

The size of the allotted areas during drilling operations depends on the purpose and depth of the wells, the equipment used and the near-well structures. So, for example, for the construction of structural exploration wells using drilling rigs with a diesel drive on a flat surface relief, plots with an area of 2500 m are required, and in mountainous areas - 3600 m. relief, respectively, is NOOO and 16,000 m. To accommodate residential settlements, depending on the number of workers, the withdrawal of the necessary land can additionally reach 7,400 m. m3 - 4500 m2. Under metal containers for collecting oil products with a volume of 200 m3, plots with an area of 3500 m3 are required.

Prior to the delivery of materials and equipment to the drilling site under construction, it is necessary to carry out work to remove the fertile surface layer of the earth. To collect liquid drilling waste and cuttings, sludge pits are built, the volume of which depends on the depth and diameter of the wells. To provide drilling clean water in the amount of 400 m3 or more, it is necessary to drill an additional well for water, which then enters the barn in the form of waste drilling water.

Oil inflows, waste and sludge can also come here. The brines have a mineralization of up to 250 g/l and they are poured into the barn. Thus, liquid and solid drilling wastes of complex composition, having aggressive components, which pose a great danger to the environment, accumulate in barns.

When drilling deep wells for oil, there are the highest environmental loads on the environment and widespread pollution of the subsoil due to poor-quality isolation of the reservoirs. Substandard materials and toxic chemicals still cause significant harm to the environment. In addition, due to imperfection and long periods of transportation and storage, materials such as cement and chemicals lose their original properties, which leads to material waste and cost.

One of the most important reserves for improving the quality of flushing and cementing wells, reducing environmental impacts on the environment is the use of the optimal amount of high-quality materials, which for exploration and production wells, respectively, amount to 25 and 30% of general expenses for the construction of wells. Great importance has a reasonable standardized consumption of material at the stages of design, planning and operational management of the well construction process. In this regard, VNIIKR Neft developed algorithms and programs for optimizing the consumption of materials for flushing and a methodology for determining the volume of waste drilling fluids during well drilling.

Accounting for the loss of binder and reagents for cementing wells makes it possible to achieve their significant savings and improve the efficiency and quality of work to isolate the layers.

4.2 Disposal of used drilling fluids

Drilling waste (RD) -these are drilling wastewater (DWW), waste drilling fluids (WDM) and drilling cuttings (BSW).

Drilling wastewater- water generated during washing of the drilling site, drilling equipment and tools; contain residues of drilling mud, chemicals, oil

Drill cuttings- a mixture of water and particles of destroyed bottomhole and well walls, drill string, casing pipes, abrasive material. It usually rises to the surface when cleaning the well with special devices (bailers, spoons, glasses, etc.). That part of the sh. b., Which is taken out of the well by the flushing fluid, is called drilling turbidity. Particles that are caught in core drilling mud pipe, commonly referred to as drill cuttings.

Waste drilling fluid is a fluid obtained after the end of the well construction cycle or part of it. OBR are formed as a result of mud running while drilling intervals composed of clayey rocks, changing one type of mud to another, as well as during the elimination of accidents and complications.

Drilling waste disposal:

OBRs that meet certain requirements can be reused to drill another well.