Sample work plan for the procurement department for the year. Standard procurement procedure. How to save money on working with suppliers: a cool case from a well-known company

RECOMMENDATIONS FOR IMPROVING THE WORK OF THE PURCHASING DEPARTMENT OF ELEKTROPRIBOR LLC

The market situation today forces all companies, even the most successful ones, to save and optimize any activity in the enterprise. Not optimizing procurement activities today is a crime against own business, therefore, I described a number of activities that will help the Elektropribor company improve the efficiency of procurement and the work of the MTS bureau.

1. One of the measures to improve the work of the procurement department is proposals for introducing a motivation system for BMTS employees.

Goals of the motivation system. The implementation of an incentive system in procurement has the following main goals:

· providing individual buyers with an additional incentive to organize more efficient procurement;

· stimulating the development of the purchasing department as a whole and its reaching a qualitatively new level of providing the enterprise with raw materials and materials;

· increasing procurement transparency.

· monthly bonus (calculated based on the results of an analysis of the percentage of fulfillment by the buyer of the requirements that determine the receipt of the bonus);

· one-time bonus payment (paid as an incentive for performing certain actions not included in the daily list of duties and job description);

· participation in the company’s profits (provided for the purchasing department as a whole based on the summarized number of indicators that affected the increase in the company’s profits);

· non-material incentives (provided for particularly distinguished promising employees based on the results of their professional activities for a certain period of time, such as a quarter or half a year).

3. Brief description of promotion methods.

1. Monthly bonus. The following point system for assessing the buyer’s performance at the end of the month is proposed in order to further encourage him.

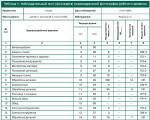

Table 3.1 - System for assessing the activities of the purchaser*

|

Indicator being assessed |

Number of points |

||

|

Inventory |

Availability on the 25th day of the current month in warehouses of standard balances of raw materials of the buyer’s product group |

The balances correspond to the standard for 60-75% of positions - 3 points. From 75 to 95% of positions - 4 points. The balances correspond to the normative ones for all positions - 5 points. Note: if at least one item does not have a minimum balance, points will not be awarded. |

|

|

Price of purchased goods |

The price of each newly contracted batch of goods must be compared with the price of the previous purchase. A price increase must be justified, a decrease entails receiving bonus points |

Price reduction for each product item: · from 1 to 5% of the previous purchase - 3 points; · from 5 to 10% of the previous purchase - 5 points; · from 10 to 15% of the previous purchase - 6 points; · from 15 to 25% of the previous purchase - 7 points; · from 25% to 50% of the previous purchase - 8 points |

|

|

Stability of supplies |

No supply disruptions, no plant shutdowns due to lack of raw materials |

Compliance with these requirements at the end of the month - 3 points. Note: if at least one delivery fails, points will not be awarded. |

|

|

Payment terms |

Transfer of “prepaid” goods to the “payment upon delivery” category - 5 points. Increasing the deferred payment period for goods delivered -- 3 points for every additional 5 banking days |

||

|

Planning |

Availability ready plan-- 3 points |

||

|

Availability of complaints |

The presence or absence of consignee claims to quality or documentation goods received from the 25th of the previous month to the 25th of the current month |

Complete absence of complaints - 5 points. Up to 2 claims - 3 points. 3 or more claims - 0 points |

|

|

Dealing with complaints |

All received complaints have been sorted out, measures and decisions have been taken on all of them - 5 points. Decisions and measures have been taken on more than 60% of claims - 2 points. Less than 60% of claims are “closed” -- 0 points |

||

|

Supplier structure, supplier assessment system |

Regular assessment of suppliers (dossier maintenance, quality control, etc.), reducing the number of intermediaries and increasing the number of manufacturers and direct importers in the supplier structure |

Status of the supplier evaluation system on the 25th of the current month: · excellent - 5 points; · satisfactory - 3 points; · no work was carried out for a month - 0 points |

|

|

Document flow |

Timely reporting (percentage of availability of accounting documents and verified deliveries on the 25th day of the current month) |

The work is less than 60% done - 0 points. The work is 60-75% done - 3 points, The work is more than 75% done -- 5 points |

|

|

Attitude to work, discipline, desire to optimize procurement |

Based on the results of the month (assessment of the head of the purchasing group) |

Active work - 5 points. There is a desire, but few results - 3 points. Working half-heartedly - 0 points |

*Source

After analyzing the buyer’s work, the points are summed up and “translated” into a bonus percentage according to the following table.

Table 3.2 - Correspondence of the number of points to the bonus percentage*

*Source

2. One-time bonus payment. A bonus payment in the amount of one or more monthly salaries can be given to an employee of the procurement department for the following achievements:

· concluding a supply agreement directly with the manufacturer necessary for the company goods with a corresponding reduction in the purchase price;

· conclusion long-term contract deliveries with a supplier of raw materials from a “strategic” group of goods with a significant improvement in conditions for the buyer (for example, delivery to the consignee’s warehouse instead of pickup, deferment instead of prepayment, provision of a cumulative discount from the price of goods, provision of additional free service etc.);

· concluding a direct import contract for the supply of goods;

· emergency purchase, which prevented production stoppage due to shortage of raw materials, if it was a consequence of force majeure or negligence of employees of other departments of the company (not the buyer!).

3. Participation in company profits. This type incentives are provided as group motivation for the entire purchasing department. It consists in the fact that, based on the results of the analysis of the group’s activities provided by its leader, general manager makes a decision on the distribution among buyers as a bonus of a certain percentage of the company’s profit received for a given period (the most convenient period is a quarter).

In addition to being a group incentive method, it differs from a monthly bonus in two other ways:

a) not all indicators adopted to evaluate the activities of the purchaser are taken into account; but only the most important for the company’s activities;

b) the incentive amount is not tied to official salaries employees, since it is calculated based on the company’s profit.

To evaluate the activities of a purchasing group that claims to share in the company's profits, the most important ones are selected from a list of standard indicators. In order to be included in the list of applicants to receive a percentage of the profits, you must meet the minimum requirements, which are indicated in the table below.

Table 3.3 - Requirements for applicants to receive interest on profits*

|

Indicator being assessed |

Required minimum level |

||

|

Inventory |

Availability of standard balances of raw materials in warehouses on the 25th of each month |

The balances correspond to the standard for at least 75% of the positions. There is no unjustified “overpacking” of goods |

|

|

Prices of purchased goods |

The price of each newly contracted batch of goods must be compared with the price of the previous purchase. Price increases occur only if there are serious justifications |

Not a single unjustified price increase during the analyzed period. On average, when analyzing the general price curve for all commodity groups, one can see either price stability with minor fluctuations, or a trend towards reducing raw material costs |

|

|

Stability of supplies |

No supply disruptions or plant shutdowns due to lack of raw materials |

Compliance with these requirements based on the results of the period |

|

|

Payment terms |

Reducing the percentage of prepayments, increasing the deferred payment period for delivered goods |

When analyzing the statistics of contractual payment obligations for the period, there is a tendency towards an increase in the time it takes for the company to fulfill payment obligations |

|

|

Planning |

Availability of a supply and payment plan for the next month on the 25th of the current month |

Availability of a payment and delivery plan no later than the 1st day of each month. Deviations of actual deliveries and payments from planned ones by no more than 20% |

|

|

Dealing with complaints |

The buyer's response to complaints, investigation and communication of them to suppliers, taking action on complaints (discounts, returns, price reduction, replacement, additional research, etc.) |

Decisions and measures have been taken on more than 60% of complaints |

|

|

Document |

Timely execution and control of reporting |

On the 25th day of each month, more than 60% of all supplies of raw materials reflected in 1C were checked, more than 60% of documents were provided for accounting |

*Source

4. Non-material encouragement.

Non-financial incentives are used for buyers who demonstrate their professionalism to the maximum, cope well with most additional requirements and demonstrate the greatest prospects in terms of professional growth.

First of all, the top management of the company should be interested in this type of incentive: it aims not only to increase the motivation of buyers, but also to improve the qualifications of the personnel available in the company, and, as a consequence, the overall level of procurement.

This type of motivation system may include incentive measures such as:

internship in a partner company (including abroad);

training (advanced training) in a prestigious educational institution, completion of any training of your choice - at the expense of the employer;

trip to a foreign specialized exhibition, seminar, conference, etc.

For this type of incentive, the buyer’s participation in any professional event that is either prestigious for the industry or will help him gain new knowledge and skills and improve his professional level is suitable.

This motivation system should help improve the quality of work of the BMTS of the Elektropribor enterprise.

2. Separation scheme product range between economists on MTS. The work between employees of the purchasing department is divided by supplier: some suppliers - to one, others - to another, others - to a third, and so on. However, in the case of ordering the same items (analogues, different in price, quality, brand - which, in principle, replace each other in the absence of one of them) from different suppliers, this practice does not always have a good effect on the results of the department’s work, with collective responsibility, when everyone is responsible, the result is that no one is responsible.

To optimize the search for suppliers, I suggest dividing the work between employees not by suppliers, but by product groups. And if only one person is responsible for ordering each product group, then there will be no overlap. In this way, each purchasing manager has clearly defined responsibility for items from his part of the product base.

3. Implementation of interaction between departments of the enterprise. The BMTS department must monitor information in the market and inform the production department (or sales department, if necessary). trading company) about new products with improved properties and greater consumer value that suppliers offer. Colleagues from other departments may not know about such products and therefore may not order them. By the way, this is especially important for production company, aimed at technological development. Thus, suppliers, in communicating with suppliers, will receive information about new technologies and products, and thanks to communication with technologists, they will have an idea of their value, and technologists will begin to take into account the price factors reported by suppliers in their requests.

4. Use of procurement on a competitive basis. Today, procurement on a competitive basis can bring significant benefits to a company, as it allows them to identify best offers suppliers. Based on the methods of conducting competitions, they can be divided into several types:

· “Paper” competition. This is a tender in which suppliers submit proposals for one or more products in sealed envelopes. As a rule, before a tender, suppliers are checked according to a number of formal criteria (for which they are required to submit a detailed questionnaire with an attachment various documents and certificates). Significant advantages of such a procedure: consistency, regulation, collegiality, formality; suppliers are aware of the deadlines for submitting proposals and closing the tender. There are also several disadvantages: the complexity of sending invitations, analyzing questionnaires, comparing different offers.

· Corporate trading platform. The competition is held in electronic form on the special website of this company. The advantages of this method: it makes it easier for suppliers to submit proposals, send out notifications and a competitive list. Disadvantages - significant financial and time costs for implementation, dependence on external developers.

· Intercorporate platform. You can post information about your competitions on special Internet portals. When choosing such a platform, you should pay attention to its reputation, reviews about it, as well as the ease of working with the portal and its technical capabilities. Be sure to analyze the proposed payment schemes for services.

Thus, the implementation of all the proposed measures will allow the enterprise LLC MNPP Elektropribor to improve the work of the logistics bureau and improve the organization of procurement activities.

The procurement department (service) is functionally a separate division firm and the input link in the logistics chain/system, so it needs to establish certain relationships with others structural divisions companies for rational organization logistics process. Main functions of the purchasing department:

1. Determining the need for material resources. To do this, the purchasing department receives information from the marketing department, production department, logistics services, operational and analytical department. Calculation of funds for the purchase of material resources. For calculations, data from accounting and finance department availability working capital.

2. Search, data analysis, selection of suppliers. This important function of the purchasing department includes a thorough research of the supplier market for products of interest, searching for the most qualified suppliers, providing necessary services before and after the sale. As a result of the analysis, the most acceptable suppliers are selected. Determining the terms of delivery and payment: negotiations with suppliers to discuss delivery terms, forms of payment, the possibility of obtaining deferred payments, etc.

3. Conclusion of contracts and control of execution. This function of the purchasing department is performed in close cooperation with the legal department, since it is important to comply with all the interests of the company in the contract. Actions in case of violation of delivery conditions. Sanctions against a supplier who has violated the terms of delivery can be of a different nature: from a simple warning or a small fine up to termination of the contract with him.

4. Obtaining material resources. Processing incoming flows of material resources, identifying products, clarifying quantities, preparing reports and moving raw materials to the place of their use and storage.

5. Checking incoming products and confirming quality. Checking and confirming that incoming raw materials, materials and services meet requirements, i.e. comply with the contract and certification.

6. To function effectively, the procurement department must have decision-making authority when making purchases in the following areas:

Selecting a supplier. The purchasing department must have experience in determining who makes the right products and how to analyze the reliability of the supplier

Pricing method. Determination of the total purchase cost to formulate the price and terms of the contract. This is one of the main areas of expertise for the procurement department. There must be room for maneuver if it is necessary to achieve minimum prices and the total cost of purchasing material resources

Certification

Control over contacts with suppliers. The purchasing department must maintain relationships with potential suppliers. If company employees (production department) work directly with suppliers themselves without notifying the purchasing department, this will facilitate “back door” sales, when the potential supplier will influence the specification finished products so that it becomes the only source of supply. If technical staff If the supplier needs to meet directly with the purchasing company's engineers, the purchasing department will organize such meetings.

The above list of tasks is one of the options for setting the powers of employees in the purchasing department of a manufacturing enterprise. In each company, the purchasing/supply department will have its own scope of authority, which will depend on organizational structure companies and logistics system generally.

Purchase of goods enterprise or trade organization- the most problematic stage of the support scheme material resources. In the article about choosing the optimal scheme for providing an enterprise with material resources, we described our vision of the idea of organizing accounting, general concept. In order to minimize the costs of storing goods and materials, but at the same time guarantee the supply of materials for the production or trade process, it is necessary to carry out part of the purchases of goods and materials directly (need -› bought), and part - to replenish stocks that can be quickly used, reducing dependence on possible delivery delays (we need to -› take from the stock in the warehouse -› buy -› replenish the stock).

In this process, the weak link most often is the procurement of goods, works, and services. Let's talk about the purchase of goods for now, but the purchase of works and services deserves a separate discussion. Sometimes by objective reasons goods are purchased with a delay, sometimes the purchase individual goods becomes impossible (for example, the required product is no longer produced). And for those responsible for procurement (suppliers), the presence of such reasons becomes an excuse even where procurement problems are caused by completely different, more trivial reasons, for example, ordinary negligence.

Minimizing these risks is an extremely important task.

It is advisable to describe and systematize the process of purchasing goods in detail, simplify and automate it if possible, recommend/impose clear rules of the game (regulations) on performers, and organize an effective control scheme. To simplify this task, let’s try to identify what parts the process of purchasing goods consists of, and consider the simplified regulations for the purchase of goods. Putting things in order sequentially in several separate, albeit interconnected, processes is always easier than taking on everything at once.

DIAGRAM OF THE PROCUREMENT PROCESS OF GOODS

Most of the actions (stages) that are carried out when purchasing inventory items are of the same type:

- calculation of the need for goods and materials to ensure production process or to carry out certain work, for example, to carry out repair work carried out in-house (supply planning);

- planning the total need for the purchase of inventories (goods, raw materials, materials, equipment) for each individual customer (for industrial enterprises more often, departments of the enterprise itself act as customers, but in a broader sense, especially for trading enterprises, the application can be aimed at satisfying the needs of external customers - our customers);

- comprehensive planning of supplies (purchases) for the enterprise as a whole;

- selection of suppliers, tender procedures;

- supply of goods and materials (registration, control of compliance with delivery conditions, capitalization, ...);

- checking the quality of received goods (on commission upon acceptance or during additional inspection, testing, certification, which can be carried out either by the enterprise itself or by external certifying organizations).

But even when the purchase of goods itself is completed, this is still far from the end of the supply process. After all, it is still necessary to organize the movement of goods to the final recipient (for example, from a warehouse to a storeroom, and from the storeroom to a foreman or foreman who will carry out the work). It would be good to inform customers about received goods, control the efficiency of receipt, delivery, and next stages- efficiency of use.

ORGANIZATION OF THE PROCESS OF PROCUREMENT OF GOODS

Most often, these stages of the procurement process are performed sequentially. But there may be a rollback on any of them. For example, if there are supply problems, you may need to look for a supplier again. In addition, at any moment something may arise that could not be predicted, for example, an emergency. This means you need to be prepared for urgent changes to all plans (procurement, supplies/purchases), urgent selection of a supplier and unscheduled purchases of goods and materials.

Each of these stages is extremely important in the overall scheme and has its own specifics. Each stage must be automated so that the entire procurement process works as a single unit.

1. SUPPLY PLANNING

To plan the material support of an enterprise means to decide in advance what goods and materials we will need and in what volumes. The best (probably even the only) way to plan the provision of material resources is to think in advance what we will do (manufacture, produce) and what need for materials is sufficient for us.

It is the rationing of inventories that allows not only to simplify the process of resource planning for the provision and purchase of goods, but also to provide logical mechanisms for controlling inventories (current inventories - for turnover, emergency inventories - for feasibility and availability). The use of rationing in the scheme of providing an enterprise with material resources builds methodological support planning into the most efficient overall process.

In order to record the existing need for goods and materials, we use “orders” - electronic documents, with which end consumers order the goods and materials they need. When placing orders, it is extremely important to decide on, i.e. where we will get the necessary goods and materials from. In our practice we use . In addition to purchasing, this is also an address reserve, own production and two types of stocks - current stock and emergency stock. More details about our recommended scheme for planning the need for materials and ordering inventory items can be found in the article.

Separately, it is worth mentioning the most important role of orders if the enterprise keeps automated records of all work carried out and actively uses it for planning software. It is orders (which, in addition to materials, can also describe work) in this case play the most important role in planning work and monitoring its implementation. However, planning and accounting of work is a separate huge topic, partially also touched upon in our articles.

2. SUBMITTING APPLICATIONS FOR PURCHASE

A significant part of the goods and materials necessary for the enterprise (raw materials or supplies for the manufacture of something, for example, for repair work) may be missing, which means it must be purchased. When planning the need for inventory and materials (when placing orders), it is advisable to allocate such materials, indicating the purchase as a source of supply. Such inventory items (those for which procurement will be the source of collateral in orders) must then be included in the purchase requisition, and the acquisition will be planned and carried out based on them.

We will look at the benefits of separate processing of orders and applications in detail a little later. Here are some of the benefits:

- undeniable management benefits from a clear understanding of why certain purchased goods and materials are required;

- the ability to avoid peak loads with quarterly or monthly procurement planning, because The need for purchased materials is determined by the contractors when placing orders, i.e. constantly, and not once a period;

- ease of control of the procurement budget in the context of individual customer departments (financial responsibility centers);

- minimizing labor costs for preparing, checking and approving purchase requests.

The purchase requisition is also extremely important for assessing the effectiveness of the organization and conducting procurement (comparing the plan and the actual supply). In this case, control over the implementation of the application can be carried out without difficulty by the customer himself, i.e. division that submitted an application for the purchase of goods and materials. But it is precisely the control of purchases by the customer/consumer, i.e. a person who depends on the availability of the requested inventory items is often the most effective. You just need to give this person the opportunity to promptly see procurement problems and evaluate them objectively.

Within the organizational structure of enterprises, purchase requests are usually submitted by departments that play the role of customers in the procurement process.

3. PURCHASING AND DELIVERY PLANNING

Sometimes it is convenient to separate supply planning and goods procurement planning. For example, by a supply plan we consider the plan in the form of “delivery time + delivery volume”, and by a procurement plan it is convenient to understand a broader essence - a supply plan plus money (cost of goods and expected terms of mutual settlements). However, these concepts are often used interchangeably.

In any case, purchase requests from multiple customer departments often contain the same items. Is information about the customer necessary for the purchase and delivery of goods? Perhaps when agreeing on a replacement for possible analogues or when clarifying the properties and characteristics of a product when selecting a supplier. At all other stages of purchasing goods, it is only important for the supplier to know what and in what volume needs to be purchased.

When organizing and planning the supply of goods, it is much more convenient and expedient to work not with tens or hundreds of requests for the purchase of goods from individual customer departments, but with something else, aggregated. For these purposes, it is convenient to use a procurement plan (supply plan). It is the procurement plan (supply plan) that will be this aggregated list of inventory items that must be purchased by the enterprise or organization as a whole.

The procurement plan for inventory resources is an “instruction for action” for the commercial service of the enterprise responsible for the purchase of goods and materials. It is also necessary and convenient for monitoring purchases carried out by the commercial service or individual responsible executors (suppliers), because It is very easy to obtain statistics on its implementation, to obtain items that were not purchased or were not purchased in full.

Highlighting the procurement plan in the inventory procurement scheme provides many other benefits, for example, the ability to organize automatic control over the posting of items not declared for purchase, i.e. to prevent “independent activities” of suppliers during procurement, when they buy “not quite” what is needed (or not at all), or when the purchase of goods is carried out in an inflated volume.

4. SELECTION OF SUPPLIERS AND CONCLUSION OF DELIVERY CONTRACTS

Regardless of who is responsible for selecting a supplier, be it the supply economist himself or a representative separate division or the organization responsible for conducting the procurement tender, it is extremely important to control the timing of the selection of suppliers.

Lack of control over the timing of the selection of suppliers can lead to the fact that the justification for the delay in the delivery of goods and materials will be constantly attributed to problems in finding a supplier. Therefore, it is desirable to have clear and effective mechanisms for analyzing delays in sourcing.

In practice, we use a graphical version of analytics, which seems quite convenient and the most visual - a graph that simultaneously displays the number of positions for which we expect to receive decisions about the selected suppliers, as well as the number of positions for which we actually have such decisions.

5. DELIVERY OF GOODS (DELIVERY, UNLOADING, ACCEPTANCE, REGISTRATION)

Effective organization of supplies is a topic for a separate discussion. The process of supplying goods (raw materials, equipment, supplies) is itself multi-stage, has its own specifics and typical problems that can be identified separately for all stages of delivery: delivery, acceptance, registration of accepted goods.

For example, during the delivery phase it is often useful to track the current location of the cargo, especially if it is passing customs clearance. This can help with organizing the acceptance of goods if warehouses do not operate around the clock.

Registration of purchased goods is also, at first glance, a fairly simple operation. What if you try to ensure the possibility of processing delivery in the shortest possible time, and at the same time achieve maximum control over delivery (compliance of the brought goods and materials with the necessary ones, correctness of the accompanying documents, etc.)?

It is important that trucks do not stand unloaded for days, and documents when transferring inventory items do not take hours to prepare. That is why we recommend “preparing” the delivery in advance, describing it at the stage of agreeing on delivery with the supplier. This allows, for example, to check in advance the compliance of the delivery with the supply plan, to minimize the time it takes to register the receipt of goods when their immediate acceptance will take place.

6. QUALITY CONTROL OF PURCHASED ITEMS

Many groups of goods are not shipped without quality control. For example, for industrial enterprises, such inventory items may include most types of raw materials (ore, chemicals), electrodes, bearings, shut-off valves.

For some types of inventory items, quality control is carried out directly at the time of acceptance (unloading), and sometimes requires a series of analyzes and measurements, which requires additional time. In addition, such quality control can be carried out by a special internal division of the enterprise that has a license (for example, a laboratory of the department technical control), and maybe an external organization.

Like all other stages, the quality control (certification) stage requires control. Otherwise, materials that are extremely necessary for production may lie in a warehouse for weeks, unavailable for delivery due to incomplete quality control.

If you aim at total control inventory, try to have information at any time about why and why any inventory items are in the warehouse, then the organization of inventory accounting and quality control time becomes an obligatory part general scheme accounting of inventory items at the enterprise.

In addition to the advantages described, at the quality control stage, with a thorough methodological study of the process diagram, it is possible to significantly simplify the activation of identified quality problems.

7. DISTRIBUTION OF INCOME

Do we always purchase the quantity of goods and materials that is required? Not always. Is one type of inventory always purchased for one internal customer? No, not always either. There may well be a situation where several departments need a hammer or safety glasses at the same time. A situation similar to the above example can occur with raw materials, equipment, and materials.

What to do when we bought less than we needed? Who should decide who to give purchased goods and materials in the first place?

In the automation scheme we use, we give incomplete deliveries that require distribution to technical service providers who are responsible for production. It is they, and not the suppliers or the computer (program), who must make the difficult decision about priority provision in difficult situations.

PROMPT RESPONSE TO CHANGES IN PURCHASING AND DELIVERY PLANS

It must be remembered that no matter how ideal the planning scheme is, there will always be factors that require urgent response and unscheduled procurement. For example, emergency situations or performer errors.

The same mistakes of the performers, refusal investment projects or other factors may lead to the opposite changes - a reduction in demand and, as a consequence, the need for an urgent refusal of goods and materials declared for purchase, a reduction in the supply plan. Otherwise, we risk buying inventory items that are no longer required, which will lie like dead weight in our warehouses.

The presence of situations that cannot be planned does not mean that decisions when agreeing on additional purchase requests or adjustments to the supply plan can be applied in such a situation without understanding the consequences.

It is essential to have full information about what led to the need to make changes to agreed plans and how the decision will affect other factors economic life enterprises. For example, in terms of the budget, it is necessary to clearly understand how additional costs will affect the cost of production.

The idea of such analysis and control is set out in the article “Prompt response to deviations from planned budget expenditures.”

So is the process of purchasing goods simple? It all depends on how important it is to manage it effectively! If there is a need or desire to purchase goods with maximum efficiency, the accounting scheme described above and recommendations for its establishment can help to achieve results faster when trying to implement such detailed accounting and control at any enterprise: manufacturing, industrial, commercial.

Key questions

How to justify a procurement budget?

How to choose a supplier?

How to conduct an inventory of balances in the warehouse and production areas?

How to counteract kickbacks?

How to establish interaction between departments within a company?

What reporting forms should be used to analyze the work of the supply department?

Companies annually lose hundreds of thousands of rubles due to abuse and dishonest fulfillment of their job responsibilities employees. Norms of management and financial accounting do not allow such cases to be detected in a timely manner. In order to reliably protect and make the most efficient use of their own assets, enterprises are implementing a system of internal control (audit), which, of course, has its own characteristics depending on the field of activity and strategic goals.

Procurement planning. Unscrupulous supply managers purchase raw materials and materials from the “correct” enterprises in quantities exceeding the volumes required to fulfill the production program. Therefore, when planning purchases, it is important to take into account not only the planned quantitative indicators (number of tons of cement, meters of cable, etc.), but also the amounts intended for the purchase of these volumes of raw materials and supplies, that is, a procurement budget must be drawn up.

Important!

To prevent abuse by purchasing managers, the enterprise must approve an economically justified purchasing budget that corresponds to the production program.

Selecting a supplier. We start with the formation of the lot, that is, we determine what exactly will be purchased and in what batches. The rules for lot formation should prevent the possibility of dividing relatively large lots into several small ones. Even if, when purchasing heterogeneous products, the prices of some suppliers turn out to be lower than the prices of the main supplier, you should adhere to the lots formed for specific type goods - a slight gain in the price of the goods can result in significant delivery costs.

The commission must approve the list of suppliers among whom the selection will be made (Fig. 1).

Rice. 1. Composition of the supplier selection committee

The commission approves the final list of the most promising suppliers. Based on the approved list, the purchasing department manager sends out identical requests to eliminate the possibility of receiving a price list for retail sales, and from the other - to wholesale.

Commercial proposals from suppliers must be brought to a single form, a so-called list of alternatives must be drawn up. To do this, the price of the product is recalculated taking into account delivery, and all conditions for deferred payment are standardized (for example, it is established that payment is made upon delivery on the same day).

Important!

The decision to select suppliers must be made collectively and approved by senior management.

Changing supplier. Nothing can be provided with a 100% guarantee, deliveries are no exception. For such cases, all procedures and procedures for managers must be prescribed in advance. “Emergency” deliveries provide ample opportunity for irregularities on the part of purchasing managers. In this regard, decisions to replace a supplier who has not fulfilled the terms of the contract must be made at the level of commercial or general director.

The fight against kickbacks. The supply sector is a “gold mine” for unscrupulous managers. In mutual settlements between legal entities The cost of a purchased or sold product is affected not only by the current market conditions, but also by the magnitude of the “rollback.” Yes, the final decision on choosing a supplier is usually made by the company’s top management (owner, CEO or financial director), but managers are responsible for the preparatory, analytical and organizational parts. “Thanks to” the efforts of the latter, only those who show a willingness to offer “interest” can be included in the list of recommended suppliers, and the person making the final decision will be slowly but surely led to the choice of the “right” supplier.

If the amount of the “kickback” does not affect the purchase price of goods or services, then there will be no negative consequences for the company. It is much worse if the “kickback” affects the purchase price of goods, especially if the transaction amount is large or we are talking about choosing a strategic supplier.

In every self-respecting company, senior management pays attention to the expenditure side of the budget and often personally controls such transactions. But such control is carried out, as a rule, according to a number of indicators. This information is prepared by purchasing managers and can be presented in any light. It is impossible to personally control the details of all transactions, just as it is impossible to be an expert in all areas.

Measures to counter kickbacks (motivating employees, introducing multi-stage procedures for additional control) do not exclude collusion within the team. Therefore, we can propose a scheme that relies on the services of third-party organizations and involves two stages (Fig. 2).

|

We counteract kickbacks |

||

|

What are we doing? |

What are we checking? |

|

|

Monitoring the market |

If you suspect suppliers of receiving kickbacks, you should instruct an employee from another service (security, internal audit or financial department) conduct a blitz audit of procurement conditions. For example, compare your procurement prices with public ones or request a proposal for the main purchased goods or services on behalf of a fictitious company (or another company in the holding, if the supplier does not know about the relationship of the companies). In the process of such research, you can find out not only the real prices of the supplier, but also get an idea of the methods of lobbying for their interests by employees of the supply department. The same work can be entrusted to an independent company that will monitor the market according to an agreed list of products or services with specified quality characteristics (including the suppliers themselves). Monitoring results are periodically sent in the form of a generalized price list to the company that ordered the monitoring |

|

|

We control contracts |

Prices in contracts concluded with the supplier, purchase orders issued or payment requests are compared with data obtained from the results of monitoring (audit). When managers try to conclude an agreement or place an order in which the cost of a specific product item exceeds a specified deviation from the average market or minimum price, the document is blocked and sent for approval to senior management ( financial director, owner, etc.). Usage information system in this case, it will allow to identify discrepancies in prices automatically |

|

Rice. 2. Anti-kickback scheme

FYI

This approach allows us to identify the excess of purchase prices over the market average or minimum both at the time of placing an order and at the stage of concluding a contract.

The main task of the supply department— ensure and maintain an optimal level of inventories, which will help minimize the costs associated with their procurement and storage. Unliquid and underutilized inventory in a warehouse is a sign of an uncontrolled and ineffective supply process. Reason large quantity illiquid assets can be:

cancellation of projects for which these supplies, materials, spare parts, equipment were purchased;

transition to another product range;

obsolescence of illiquid assets;

inconsistency in the work of the supply department and other services, untimely notification of the procurement service about the cancellation or reduction of the production program by type of product, etc.

Inventory will help identify illiquid stock or excess inventory. Usually on manufacturing plant In addition to the central warehouse, there are workshop and district warehouses; in addition, materials and other supplies can be stored by foremen and foremen. The supply department can only monitor the central warehouse, and everything else, as a rule, is uncontrolled. A general inventory will help identify the real size of stocks and optimize subsequent purchases. For greater efficiency such an inventory must be carried out periodically with the involvement of employees of an independent internal audit service or third-party organizations.

Establishing interaction between departments within the company. The supply department must monitor the market and inform the production departments (or the sales department, if it is a trading company) about new products with improved properties and greater consumer value that suppliers offer. Colleagues from other departments may not know about such products and therefore may not order them. This is especially important for a manufacturing company focused on technological development: suppliers will receive information about new technologies and products from suppliers, technologists will receive information about their value, and technologists will take into account price factors reported by suppliers in their requests and when drawing up budgets for future periods. .

Important!

For an effective supply process, it is necessary to establish interaction between departments of the company.

The procurement department's reporting forms allow you to control the procurement process. From them you can obtain information about price changes, the quality of supplied products and the fulfillment of procurement deadlines (Table 1).

Table 1. Analysis of the work of the procurement department by price

|

Manager |

Price, rub./kg |

Unit of measurement |

Purchased, kg |

Price change |

Purchase amount, rub. |

|||

|

January 2015 |

February 2015 |

|||||||

|

Manager Sukhorukov M.I. |

||||||||

|

Premium flour |

||||||||

|

First grade flour |

||||||||

|

Second grade flour |

||||||||

|

Manager Loginov V.M. |

||||||||

|

Premium flour |

||||||||

|

Total for the department: |

||||||||

The purchasing manager, whose prices rise faster than others despite significant purchase volumes, needs to be additionally monitored.

Purchasing departments base their work on an ironclad argument - the price of purchased raw materials. I bought it cheaper - well done. You bought it expensive - it’s bad, you don’t know how to work. What then happens in production, in the technical control service and sales is no longer a problem for the supply department. Therefore, when making deliveries, it is very important to check the quality of the supplied products, on which the consumer qualities of the products manufactured at the enterprise depend.

We recommend keeping statistics of problems with purchased raw materials during incoming inspection, during storage and during use in production. Keeping records is not difficult: the base is formed from accounting for each single problem in the supply of raw materials. For each problem, we draw up a report in which we write who, when and in what form supplied the problematic raw materials/components. Combine all these acts in the form of reports with the ability to sort in the 1C program or a simple Excel file - and the database is ready (Table 2).

Table 2. Analysis of the work of the supply department in terms of quality

|

Supplier name |

Delivery date |

Contract number |

Quantity of goods supplied, kg |

Type of nonconformity |

|

Rostock LLC |

No. 25 dated December 25, 2014 |

During the acceptance and incoming inspection process, it was discovered that the moisture content of the flour was 18% (the norm is 15%) |

||

|

OJSC "Agribusiness" |

No. 20 from 12/20/2014 |

During the acceptance and incoming inspection process, it was discovered that the ash content of premium flour in this batch is 0.6% (the norm is 0.55%) |

||

|

LLC "Zernotorg" |

No. 18 from 12/15/2015 |

During the acceptance and incoming inspection process, a musty odor was detected in the flour of this batch. |

Based on such data, a decision is made on whether to continue cooperating with problematic suppliers.

In order for the production program to be completed on time, all necessary components must be delivered on time. The following form allows you to analyze the factors that impede timely delivery (Table 3).

Table 3. Analysis of the work of the supply department in meeting delivery deadlines

|

Full name purchasing manager |

Execution of the plan for product names (articles) |

Failure to meet delivery deadlines |

||

|

Number of times |

||||

|

Sukhorukov M. I. |

||||

|

lack of funding |

||||

|

accident at a railway crossing |

||||

|

Loginov V. M. |

unfavorable weather conditions(snow drifts on the roads, ice) |

|||

|

lack of funding |

||||

|

strike of workers at the supplier's enterprise |

||||

|

Total by department |

||||

This form of reporting makes it possible to analyze the reasons for “failures” in delivery times, to identify which of them depend on external factors(dishonesty of suppliers, natural factors, force majeure, etc.), and which ones are internal (for example, lack of timely financing) and take measures to prevent these situations in the future.

Conclusions

- The internal audit system is effective only if the developed regulations and recommendations are followed by company employees.

- Employees must look for the best offers, options for obtaining significant discounts, promptly check stock balances, and take into account expected significant fluctuations in prices for supplied goods.

- The functions of company employees must be clearly defined.

- Effective mechanisms for monitoring the performance of the supply department are needed.