Mineral water business plan how to implement. Ready-made business plan for the production of mineral water with calculations. How to start a mineral production business

- Recruitment

Manufacturing business mineral water has always been considered highly profitable. An endless raw material base, combined with a wide selection of water bottling equipment (both domestic and foreign) make this business very attractive to investors. However, due to the saturation of the market for such products, starting a business for new players is becoming more and more difficult. The issue of sales in this case is always in the first place.

Mineral water bottling business

From year to year in the production market drinking water new companies and mini-productions appear. So how profitable is the mineral water business? We invite you to familiarize yourself with the feasibility study (business plan) for the production of mineral water at a mini-enterprise with a capacity of 12 thousand liters. water per shift.

Mineral water production technology

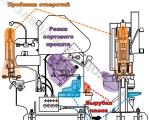

To begin with, we will briefly present the technological chain of mineral water production:

- Accumulation of water in receiving tanks. Mineral water from wells (300-400m) is lifted by a deep pump and fed through pipelines to storage tanks.

- Filtration. Water filtration is carried out on a filter block filled with sand and filter material.

- Disinfection. Disinfection of water is carried out by ultraviolet rays in the UV installation.

- Cooling. Water cooling takes place on a plate heat exchanger.

- Saturation with carbon dioxide.

- Blowing PET bottles (1.5l) on a special blow molding machine.

- Bottling and supply of finished water to the warehouse. Mineral water is poured into 1.5l PET bottles, sealed with corks, labels marked on the printer are pasted on the bottles. The bottles are packed in shrink films in 6 pieces, stacked on pallets and wrapped with a stretch film on a politizer. Then the finished product is sent to the warehouse.

How to start a mineral production business

Let's calculate the main indicators economic efficiency mini-enterprises for the production of mineral water.

Initial data:

- Production area: 400m2

- Type of ownership: rent (120 thousand rubles/month);

- Number of shifts: 1 shift (8 hours);

- Line productivity per shift: 12,000 liters (8,000 bottles of 1.5 liters each);

- Number of working days in a month: 22 days.

- Capital cost of bottling equipment

What equipment to choose for the production of mineral water

Capital costs for the purchase of equipment for the production of mineral water will amount to 1,100,000 rubles.

Recruitment

Monthly payment costs wages employees will amount to 1,272,000 rubles.

How much money is needed to produce mineral water

The cost of production of one liter of mineral water is 8.94 rubles. General expenses per month will amount to 2,363,600 rubles.

How much can you earn in the production of mineral water

Let's calculate the main indicators of economic efficiency of mineral water production, including the payback period of equipment.

Conclusion: The net profit of the enterprise for the production of mineral water will amount to 686.7 thousand rubles per month. The profitability of production with such indicators is 29%, and the payback period for equipment (not business) is only 1.5 months. It is worth considering that such indicators are possible only if 100% of the sale of all manufactured products, which is 264,000 liters of mineral water per month.

- Privacy.

- Summary.

- Stages of project implementation.

- Characteristic of the object.

- Marketing plan.

- Technical and economic data of the equipment.

- Financial plan.

- Risk assessment.

- Financial and economic justification of investments.

- Conclusions.

Business plan

Download business plan

Reviews (16)

Even a child knows that drinking tap water is harmful to health. That is why interest in such a product as clean drinking water is growing every day. The demand is especially high in large cities. It is there that there is a reason to plan the organization of a business for cleaning and bottling water. Before opening the production of bottled water, it is recommended to analyze all available options for entering this business.

As a rule, businessmen who pay attention to the water business can be divided into two categories: those who risk building a business for the production and delivery of water from scratch, and those who prefer to start operating under the wing of an already famous company. Each of these options has its own advantages and disadvantages.

Businessmen who have significant initial capital investments usually decide to open their production for the extraction and bottling of water. Entrepreneurs experiencing some shortage financial resources, are inclined to the second option, which implies cooperation with a company already promoted on the market.

As the analysis of the drinking water market shows, the demand of buyers for this product is constantly growing, however, so far this applies mainly to large cities. The volume of the mineral and drinking water market in Russia is about 25 billion liters per year. This means that every entrepreneur has a chance to occupy his niche. Organization of the production and sale of bottled water requires considerable initial investment, and this must be taken into account when choosing a way to enter this business.

The most expensive is the production of a full cycle - from the extraction of water, its purification and delivery to customers. In addition to developing his own well, the entrepreneur will have to invest in the construction of his own enterprise, which will be engaged in water purification and bottling. Moreover, the expected results of the project for the construction of a plant for bottling drinking water do not always coincide with the real state of affairs. The payback of bottling and water purification devices is not so high, and the risk of failure is very high.

Much lower costs are required if the businessman decides to act in cooperation with the existing company. In this case, two options are possible: dealership and franchising. By purchasing a franchise, the entrepreneur practically does not risk his own money. By investing in an already promoted business, a businessman gets the right to support, which is expressed in consultations, the opportunity to use effective marketing ideas of the company.

The easiest way to enter the business is dealership, that is, the sale of finished products. The peculiarity of the business is that a company engaged in the wholesale of mineral and drinking water sells goods to its dealers at a big discount. There are also options for buying and installing vending machines selling artesian water. You will learn about all the intricacies of this type of business, including running a company selling water, by carefully reading an example of a business plan for the production of drinking water with ready-made calculations. As practice shows, it is a competent water production business project that helps a businessman to succeed, regardless of which option he chooses to enter the market.

When opening a business on artesian water, a businessman, first of all, thinks: who will buy it? Despite the growing consumption of clean drinking water, it is very difficult for companies specializing in the business of selling mineral water to find their customers. Entrepreneurs place their main bet on offices, which are the main consumers of bottled water. Experts predict that this market will only develop in the future.

How to profit from the water and create a sustainable operating business- a topic for reflection for many entrepreneurs. After all, only at first glance it seems that running a water delivery business is the simplest thing. In fact, a businessman faces many problems along the way. Of course, starting your own water delivery business is much easier than opening a water bottling business. But even here there are pitfalls.

Disparities and amounts of costs that are necessary to create two different companies. In the first case, investments in the project will amount to approximately 80-100 thousand dollars. The second option provides for more modest investments - only 15-20 thousand dollars. Therefore, carefully consider your financial capabilities.

Organizing a business for the delivery of drinking water to offices and homes is easier than keeping it afloat in difficult conditions. If a water manufacturer can easily become a monopoly in a certain region and open a drinking water bottling business in any city, then a delivery company does not have such opportunities. Competition in this market segment is fiercer, which complicates business tactics. Therefore, the entrepreneur should focus on the quality of the services provided.

Particular attention should be paid to water quality: this applies to the choice of supplier and storage conditions of purchased products. When purchasing water for sale, find out in advance from which artesian well it is pumping. The water treatment business is quite expensive, so some companies try to save on this by supplying water to the market that does not always meet the standards. And you, as a seller, will also be responsible for the quality of the water sold.

The organization of a water delivery company provides for its constant promotion in the service market. Convincing a potential buyer to give preference to clean and safe water is still difficult, and this is often helped by tasting in the office, the owners of which are the main buyers of bottled water. Most likely, they will feel the difference in taste, which will become the main motive for buying.

If you have questions in the process of creating a business, look for answers to them in a professional sample business plan for bottling, selling and delivering bottled mineral water. After getting to know him, you will understand how profitable the water delivery business is. Take a look at this document and you will understand how much easier it has become to act.

Water production as a business- a rather laborious and complex process that can bring a good income, but only if the process is properly and competently organized. Today, almost everyone knows that drinking water from the tap is undesirable, since it does not always meet the standards. Someone buys water only for drinking, others - both for drinking and for cooking, coffee, tea.

According to statistics, despite the obvious fact that tap water is harmful, about 30% of people constantly buy purified water in stores, but it is obvious upward trend.

Filters can be a good option, but they are not always effective, clog quickly, and require regular maintenance and replacement. Therefore, the organization of a business for the production of drinking water is relevant today more than ever.

Features of the organization of the case

Before starting production, you need to familiarize yourself with current legislation – Laws on subsoil resources, ecological expertise, tax code, resolutions and regulations, rules. If you plan to extract water, you need to take care of obtaining permission from local governments to drill a well, use a land plot to extract groundwater, and a bottling enterprise project.

You will need to register a business, obtain SES permits, Gosstandart certificates, in some regions, in order to sell goods, you will need to obtain a license from the Chamber of Commerce.

When developing a business plan for the production of drinking water, there can be two options: extract it yourself or take it from a tap that has undergone special treatment. If you choose the second option, then we are talking about a water treatment system. The technology is quite simple, but requires the purchase of special equipment to disinfect and enrich water with oxygen. With proper organization, the costs quickly pay off, since the production of drinking water is.

Before bottling, water undergoes ozonation, as well as several other stages.

For them you will need:

- ORP controller and ORP sensor

- ozone generator

- inverter pump

- Thermal catalytic ozone destructor

- Fittings, valves

- Automatic Duplex Air Dryer

- Level sensors, automatic start

- Blow molding equipment (bottles)

- labeling machine

If you plan to take from the well, you will also need:

- Fine and coarse filters

- borehole pump

- Mechanical filling device

- storage tanks

To organize production bottled water with an automated line, you will also need: a filling unit for siphons, canisters, bottles; block of water weakening, saturation, strong purification. The equipment costs a lot, but you can’t do without it; when buying, you must definitely require certificates and examination results, compliance with standards and documents.

Business plan for the production of drinking water: basic calculations

To understand whether it is profitable to engage in bottling of drinking water, it is necessary to calculate all costs in advance. Much depends on whether you plan to fully automate the system or involve employees. If people work, their salaries are added to the calculations, if equipment is purchased, its cost.

The main expenses according to the business plan for the implementation of the project:

- Acquisition of a plot of land - prices may be different, depending on the region, district, location features (for drilling a well, if water is taken from the tap, this item is excluded)

- Purchase of equipment- the amount can also be different, depending on the volume of production

- Installation of equipment - the same factors affect the final figures

- Lease or - depends on the size of the area, location, terms of lease-construction, etc.

- Wage employees

- Payment electricity, water(from a tap or extracting it from a well)

- Advertising campaign- in order to buy water, you need to think over the name, slogan, label design, press release, offer for partners, etc.

- Expendable materials

In general, such a business can bring good profits and pay off in six months or a year, subject to the full sale of the goods.

Features of the mineral water bottling business

It is generally accepted that all mineral water sources have been occupied for a long time, but this is not so. After all, we are not talking about special properties, but about any water that was extracted from lower horizons of groundwater. The degree of mineralization can be different, it differs from drinking water by the presence of special mineral compounds. The composition of mineral water is: bicarbonate, chloride, sulfate. It can be dining (up to 4.5 g / liter of minerals) or medicinal (more than 4.5).

To organize the production of mineral water, you will also need to draw up documents and obtain all permits, as in the case of drinking water. Here it is very important to choose the right equipment, the cost of which can be high, so buying used equipment is often considered.

AT production business plan mineral water, you need to make a purchase of the following items: a capping and bottling machine, water tanks, pumps for a well, a saturator, equipment for creating bottles from blanks, for packaging.

Unlike drinking clean water, which can be taken from the tap and processed, in this case, drilling a well is indispensable. There is an option to purchase water from an already operating well, and in some cases it is more profitable than doing everything yourself. A plot of land and the well itself must be transferred to private ownership or they agree on a long-term lease for at least 50 years.

Mineral water: main stages of production and business plan

Production involves some features and related costs, which must be taken into account.

The technological chain in this case involves the following steps:

- Lifting water from wells with a depth of 300-400 meters using a deep pump and pipeline, accumulation in tanks

- Filtration - on a special block, filters and sand

- Disinfection - in the UV unit

- Cooling - on a plate heat exchanger

- Saturation carbon dioxide

- Blowing bottles with a capacity of 1.5 liters on the machine

- Water bottling and supply to the warehouse, corking, labeling, packaging of 6 bottles in shrink film

- Palletizing, packaging, shipping

Considering the production of mineral bottled water as a business, you can take different amounts of initial costs, which depends on whether there is a well, how much is needed in order to start drilling, whether delivery from other places is planned. Unlike the usual cleaned or distilled one, not any well is needed here, but a well drilled under specific view water.

In general, the costs look like this:

- Premises for rent an area of 300-400 square meters.

- Capital costs for equipment - 1,100,000 rubles: a pump for a well - 30,000 rubles, a soda water dispenser - 650,000 rubles, filters - 100,000, blowing equipment - 70,000, sterile tanks - 40,000, a semi-automatic bottle capper - 120,000, a labeling machine - 90,000 rubles.

- Payment for the work of a technologist, handyman, warehouse manager, equipment master, accountant and sales manager will cost another 1,270,000 rubles per month.

In general, the costs amount to about 2,400,000 rubles. If we take into account that the productivity of the line per shift is 8,000 bottles of one and a half liters (12,000 liters), and the number of working days per month is 22, it turns out that the net profit per month can reach 500,000-600,000 rubles.

This is enough high profitability, which will allow you to return the cost of equipment in a few months, but the business plan involves the sale of all manufactured products, which requires additional investments in advertising and marketing.

Drinking water today is bought not only for the home. It is ordered to offices, institutions Catering, hospitals, children's institutions, production shops. There will always be a demand for this product, because at any time of the year a person simply cannot live without it. Of course, such an important product cannot be left without the attention of modern entrepreneurs. The production of mineral water is one of the promising and inexpensive business ideas.

It may seem that there is no simpler commodity than drinking water. However, there are many types of it. The main groups are mineral table species, natural table and medicinal. The first type contains at least 1-2 g of salts per liter. In addition, the composition contains pharmacologically active components. There are more salts in medicinal table waters. They contain biologically active components. Medicinal species are products in which the total mineralization is not less than 12 g per liter. They can only be used as directed by a doctor. According to the amount of capacity in the product of anion exchangers and cation exchangers, table waters are divided into 19 groups, and medical table waters into 28 classes. There are about 160 species of the former, and no more than a hundred of the latter.

What equipment to choose for the production of drinking water?

The line for the production of bottled drinking mineral water costs about 1 million rubles. The set of equipment includes:

| Saturator or carbonation plant | It resembles a cylinder in which a certain pressure is created. It is controlled by a valve, the level is shown by a pressure gauge installed on it. Before saturation with carbon dioxide, the water is cooled to 6 °C. |

| Filling and capping machine | It rinses, pours soft drinks into PET containers or glass bottles, from 0.33 to 19 liters. The equipment can be sealed with a plastic cap, crown cork or aluminum cap. |

| well pump | Mineral water is considered to be water that is extracted from a depth of 100 meters or more. The equipment must be powerful enough to pump it out and send it to the production line. |

| Water tanks | Used to store drinking water before and during processing. |

| Block for the production of PET bottles | Forms a container into which the product will be poured in the future. |

| Packaging equipment | Serves for packing bottles into briquettes, convenient for further transportation and storage. |

Drinking water production technology

The production of bottled and bottled drinking water takes place according to this technology. Water from wells is supplied to special containers. It rises through pipes, with the help of special deep pumps. In such drinking water there are always mechanical impurities. To get rid of them, the water is carefully filtered. If this is not done, then the product will sooner or later become cloudy and deteriorate. Industrial filters are made from well-known materials: coal, sand, and others. On the next step water is purified from biologically active organisms. For this, ultraviolet radiation is used.

Not all mineral water is carbonated. As practice shows, the product without gases is in less demand. Therefore, in order to achieve the desired level of sales, water must be passed through a saturator. He will saturate her with carbon dioxide. Cool the water in the heat exchanger. Carbon dioxide is also dissolved there.

In modern factories, containers for the product are made by themselves. Installations for its production do not take up much space, and production does not depend on suppliers. Branded stickers and a special design is another important feature that affects sales and success. marketing policy enterprises.

Container for mineral water.

Ozonation of bottled drinking water

Saturation of water with oxygen (ozonation) relieves the liquid of harmful microorganisms, disinfects it and even gives it some healing properties. Oxygen that enters the water does not affect its mineral properties, but it improves the taste and makes the product useful for humans. It has been proven that the cellular structure of water that has passed through ozonation is similar to the structure of human blood. The body processes it more easily.

An installation in which ozonation takes place (saturation of water with oxygen) can be purchased for 260 thousand rubles. It has a certificate of conformity ROSS RU.AB67.H00706 No. 0276073. The water passed through it complies with domestic norms and rules. In the installation you can:

Such equipment is capable of producing ozonation from 50 to 500 liters of drinking water per hour. It is a single housing that does not require special installation. The technology does not consist in carbonation, but in filling drinking water with oxygen at the ionic level. The output is a liquid that contains 40 mg per 1 liter of dissolved oxygen.

Ozonation of mineral bottled drinking water in production is carried out immediately before bottling into containers. The ozone level in such liquids is 0.2-0.3 mg/l. They can be usable for quite a long time.

Ozonation occurs in a very short time, but nevertheless, it allows you to disinfect the product and the container. Ozone also affects the bottling system itself, the cap, bottle neck and other elements involved in the process. After the bottle is hermetically sealed, the ozone molecules turn into oxygen. This process renders the product practically sterile prior to consumption. Ozonation is mainly applied at the last technological stage.

In the end, it should be noted that on average in the industry, the production of drinking mineral bottled water has a profitability of about 30%. With such an indicator and subject to the full sale of products, the investment promises to pay off within 12 months. The term, accordingly, will increase if more expensive equipment is purchased and the production premises are bought out.

What equipment to choose for the production of mineral water

To organize a small production of mineral water, a novice entrepreneur needs to purchase special equipment. Depending on the available finances, this may be new or used equipment. There is also an option to purchase each machine separately or purchase a ready-made automated production line.

For the production of mineral water, you need to buy the following elements:

- downhole pump;

- coarse and fine filtering units or an automatic system;

- bottle production equipment;

- reservoirs and tanks for water;

- bottle filling and capping machine;

- apparatus for the production of labels.

Mineral water production technology

The mineral water production technology consists of several stages. During the production process, water undergoes some treatment. Mineral water is pumped out by special pumps from wells 300-400 meters deep and lifted into storage tanks. Then the water enters the filter unit, where it is cleaned with filtration materials in two stages - coarse and fine cleaning, and is also disinfected with ultraviolet rays. Before filling the mineral water with CO², it is pre-cooled on a plate heat exchanger. After that, on a special production line, carbon dioxide is saturated, the solubility of which in water depends on temperature and pressure.

Pre-prepared preforms are fed into the bottle making machine, where they are heated and pressurized into the final shape of the containers. On the last step mineral water is poured into PET bottles, corked with plastic stoppers, and a marked label is glued. finished products packed in a shrink film for 6 pieces, stored or immediately delivered to customers.