Factors for the location of light industry. The main features of the location and territorial organization of industry and its branches in Russia, the interzonal division of labor. What are the factors for the location of light industry enterprises?

Light industry- a set of specialized industries that produce mainly consumer goods from various types raw materials.

Light industry carries out both primary processing of raw materials and production finished products. Light industry enterprises produce industrial, technical and special purpose, which is used in furniture, aviation, automotive, chemical, electrical, food and other industries, agriculture, law enforcement agencies, transport and healthcare.

One of the features of light industry is quick returns cash . Technological features of the industry make it possible to quickly change the range of products at a minimum cost, which ensures high mobility production.

Light industry unites a group of industries that provide the population with fabrics, clothing, shoes and other consumer goods

Features of light industry:

The industry's products affect people's living standards;

Labor-intensive industry, which employs mainly women (75% of workers);

The size of the enterprises is small and does not require large amounts of energy and water.

The main raw materials of light industry are products agriculture both crop production (cotton, flax, etc.) and livestock production (leather, wool, natural silk, etc.).

Scientific and technological progress plays a significant role in the expansion and spatial orientation of the raw material base for light industry. Based on organic synthesis, in the areas where petrochemical enterprises are located, the production of synthetic materials has increased significantly: fibers and threads, plastics, rubber, artificial leather. As a result, raw materials seemed to move closer to the places of production and consumption of finished light industry products, since the chemistry of organic synthesis, as is known, is located in areas of concentration productive forces. Share of chemical fibers used, in total volume processed raw materials account for more than 30%. The degree of use of chemical raw materials in the light industry of economically developed countries is much higher and continues to increase.

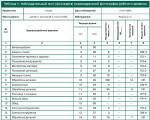

Light industry sectors (with the exception of primary processing of raw materials), according to their affinity for sources of raw materials and areas of consumption, are divided into the following groups shown in Figure 11.1.

Figure 11.1 - Light industry sectors

The importance of light industry in the future should increase, which will undoubtedly be influenced by the sociologization of the economy in market conditions, available raw materials, as well as the availability of qualified personnel.

However, it can be assumed that, in general, Kazakhstan’s light industry products will not become competitive on the world market in the near future. This is due, firstly, to the fact that the country, due to climatic conditions, does not have enough of its own natural raw materials in the form of cotton and silk, and secondly, the competition on the world market is too strong from southern countries located in more favorable conditions a combination of a significant amount of raw materials and labor resources (China, India), as well as economically developed and traditionally trendsetters (Italy, France).

Main problems of the industry:

- low level wages;

– use of outdated equipment. Since 2005, the annual renewal of equipment in the industry has not exceeded 3-4%, in economically developed countries - 14-16%;

– high share of illegally imported goods in the consumer market. Most enterprises are concentrated in the provinces;

- shortage of enterprises own funds for the development of production.

2. Problems of light industry:

Flax growing

The main supplier of natural raw materials for light industry is agriculture. Flax growing is in a very difficult situation. From year to year, fiber flax crops are being reduced, and its yield is falling. Flax growing is unevenly distributed. Currently, the issue of reviving domestic flax growing to replace purchased cotton is being resolved.

Wool. Natural wool comes mainly from sheep, a very small share (less than 1.5%) comes from goats, etc. The quality of supplied wool has sharply deteriorated, the bulk of which does not meet international standards:

Total 8% domestic market clothing in Kazakhstan is provided by domestic products (in the related footwear industry this figure is 1%). And even then, these are mainly uniforms and shoes for the armed forces and police;

The first months of this year again showed a decline in light industry. The tax burden in light industry continues to be the highest compared to other sectors of the economy of Kazakhstan.

The territorial organization of light industry is determined primarily by the influence of consumer and raw material factors. Each of these factors influences differently - depending on the stages of production and the technical and economic characteristics of a particular industry. In addition to industry and consumer factors, great value has the provision of a particular territory with labor. It should be noted that the main workforce at light industry enterprises is women.

Enterprises for the primary processing of raw materials have a significant amount of waste (up to 30-40% of the weight of the raw material output) and therefore gravitate towards raw material bases. Fiber crops are processed in the places where they are grown, and animal raw materials can be processed far from raw material bases. Thus, primary processing of wool can be carried out along the route of transportation of raw materials in the presence of water and fuel supplies. The location of leather production can be combined with both an animal base and a meat consumption center.

The location of light industry (especially its main branch - textile) is greatly influenced by scientific and technological revolution. This is reflected primarily in concentration textile production, to changes in its raw material base. Natural fiber is gradually being replaced by chemical fibers, since the production of chemical fibers is easier and less expensive. A large number of fabrics are produced using a mixture of natural and chemical fibers.

In the leather industry, artificial leathers occupy a significant place, since natural leathers are expensive raw materials, and it is not possible to use large number genuine leather in production.

The organic synthesis industry as a raw material base for light industry has dramatically changed the conditions for locating its enterprises in certain areas.

Unlike the primary processing of raw materials, the production of finished products is characterized by a more complex placement. When choosing a placement option, raw materials, consumer and labor factors. The main role is played by the factor of labor resources, because light industry is the most labor-intensive industry and, at the same time, the population is the consumer of finished products. Thus, areas supplied with labor resources massively consume light industry products and thereby create favorable conditions for the location of its enterprises.

WORLD CENTERS OF LIGHT INDUSTRY

The most important type of natural fiber is cotton, which accounts for about half of the world's processed textile raw materials. The largest producers of cotton fiber in the world include: China, USA, India, Pakistan, Uzbekistan, Turkey, Austria, Egypt, Argentina, Brazil.

Exporters of cotton fabrics: Pakistan, USA, China, India, Japan, Russia. The main importers are the leading countries of Europe, Canada, Australia.

The share of woolen fabrics in world production is insignificant, but the share of wool in their total cost is large, because wool is an expensive type of fabric. Woolen fabrics mainly contain synthetic impurities. Largest producers woolen fabrics: China, Italy, Japan, USA, Korea, Germany, Great Britain, France, Russia. Most of these countries are exporters of woolen fabrics, and the main producers and exporters of raw materials - wool - are the following countries: Australia, New Zealand, China, Uruguay, Argentina, South Africa. The main importers are European countries and a number of North American countries.

In the production of silk fabrics, artificial and synthetic fibers are of great importance. Cellulose silk, nylon, nylon have successfully replaced natural silk, but recently the importance of natural silk has been increasing. This is explained by the fact that it is impossible to recreate certain properties of natural silk artificially. The main producers and exporters of natural silk: Japan, Korea, China, India, Russia.

Other types of textile production include the hemp-jute and flax industries. The largest jute industry is located in India and Bangladesh using its own raw materials, and in the UK using imported raw materials. The main importers of hemp and jute products: USA, European countries.

The flax industry is developing in Russia, Belarus, Ukraine, Poland, and the Baltic countries. There is also the production of rope and wicker products from abaca, sisal, and henequin. The main producers of products from abaca are the Philippines, from sisal - Tanzania, from henequin - Mexico.

If we consider the location of the textile industry as a whole, it should be said that the industries are expanding every day in many countries of the world, regardless of their level of development. But for developing countries, light industry is one of the leading sectors of the economy, and they often compete very successfully in the markets of developed countries. More successful competition is currently hampered by the low level of production, defective first-class equipment, and the predominance self made. At this time, the influence of these factors is decreasing.

The cotton sub-sector occupies a leading place in the textile industry of developing countries. In India, Bangladesh, Syria, Pakistan, Argentina, the cotton industry developed before the Second World War and belongs to traditional industries. In New Industrial Countries this industry has emerged recently, but on a modern technological basis.

The top ten producers of cotton fabrics include both developed countries and developing countries. But if we compare the scale of production, then, of course, in this indicator it is the developing countries that are ahead. In the production of fabrics from chemical fibers, developed countries are still ahead, but the importance of developing countries in Asia is constantly growing. The production of silk and wool fabrics is more common in developed countries. The location of the leather and footwear industry is primarily consumer oriented. Large areas of the leather and footwear industry are concentrated in developed countries: the USA, Italy, Great Britain, France, Germany. Significant shoe production has also been established in Poland, Ukraine, Romania, Russia, Bulgaria, the Czech Republic, Hungary, and Finland. As for the production of raw materials, it is concentrated in livestock-raising areas, where raw hides are a by-product in the production of meat and meat products. The supplier of synthetic materials is the chemical industry.

The clothing industry is very widespread. Its enterprises are represented in all groups of countries, on all continents. This branch of light industry tends to cluster in urban areas. But the general level of development of the clothing industry, its technical equipment, and the quality of garments are characterized by higher indicators in European countries, the USA, Canada, and Japan. The market for relatively cheap goods in the clothing industry is concentrated in the New Industrial Countries and individual developing countries that have an advantageous geographical location.

The fur industry is one of the most expensive sub-sectors. It requires very high quality raw materials. Currently, more than 80% of the global fur industry is based on Russian raw materials.

are:

consumer. Finished products of light industry are less transportable compared to semi-finished products;

labor resources, providing for their availability and qualifications, since all branches of light industry are labor-intensive;

raw material- affects the location of enterprises primary processing agricultural raw materials.

2. Textile industry

produces one of the main

consumer products - fabrics.

Without fabric, it is impossible to produce clothing, along with food,

how necessary for the population. Fabrics are also used

as raw materials and auxiliary materials in other sectors of the economy - mechanical engineering, chemical industry, etc.

The leading industry in the structure of the textile industry is cotton. The main area of concentration of the cotton industry is Central economic region .

The first place in terms of production volume is occupied by Ivanovo region, producing almost 70% of cotton fabrics in the country . Next come Moscow and the Moscow region, the Vladimir region.

The bulk of textile industry enterprises, regardless of the type of sub-industry, are located in the European part of the country.

A special feature of the textile industry is that the majority of workers in this sector of the economy are women.

Also important in the overall structure of light industry are:

Linen;

Wool;

Silk industry.

3, Enterprises clothing industry

distributed more evenly throughout the country than textile enterprises.

They are available in almost every region and provide

predominantly internal needs.

A special feature of the clothing industry is that most of its products are produced in small enterprises scattered throughout the country.

In recent years, there has been a trend of opening in Russia branches of famous foreign companies in the field of tailoring, creating joint ventures.

This is facilitated by the fact that since the mid-1990s. The demand for foreign clothing models, which are considered more prestigious and superior in terms of artistic design, has sharply increased. Many Russian clothing enterprises are also trying to adopt advanced foreign technologies.

4. Shoe production

-

an industry with a rapid change of assortment, aimed at the mass consumer. Feature

industry is that its products are also goods

essentials. Leather is close to shoe production

haberdashery industry that produces bags,

gloves and mittens, cases, sports equipment, etc.

Modern problem footwear and leather goods industries - insufficient capabilities of the domestic raw material base. Currently, 1/3 of all raw materials consumed for the production of shoes and leather goods are imported.

Enterprises in the shoe and leather goods industry are mainly concentrated:

In Moscow and the Moscow region;

Kirovskaya;

Tula;

Penza regions;

Republic of Bashkortostan;

Chelyabinsk and Tver regions;

Stavropol region.

In structural adjustment the Russian economy has an important place increasing the share of consumer complexes. Meanwhile there is no noticeable expansion of regional specialization in this direction.

In the European part, only 2 new areas of specialization for primary battery appeared, while in the East - not a single one. Having powerful production potential industrial goods consumption in the Urals and Western Siberia has not reached the level of those specializing in them.

Current problems accelerated rise of consumer industries and improvement of their regional structure are:

Widespread activation of the consumer sector of the national economy in order to fully provide the population with consumer goods, and industry with agricultural raw materials; radical improvement in the quality and range of products, taking into account the technical, economic (labor intensity, profitability) and regional characteristics of the industries;

All-round intensification of agricultural production in various regions on a machine and agrotechnical basis, for which it is necessary in agricultural policy to give priority to the development of large farms various forms property, turning them into high-commodity and low-cost ones with the expansion of various types of production and supply and marketing cooperation;

Development and strengthening measures state support rational specialization of agriculture in natural economic zones as an important condition for the growth of labor productivity and marketability of production;

Special attention to filling the market with goods for cultural, household and household purposes, where the lag in consumption from the world level is most noticeable; improving the technical, consumer and aesthetic properties of manufactured products, primarily household appliances, facilitating work and reducing costs in the household; emphasis on the production not of individual products, but of entire sets of such equipment;

Wider use in the development and location of consumer industries of the advantages of the territorial division of labor instead of the dominant concept, which considers them only as service units of the regional economy; strengthening zonal specialization of agriculture; organization of systems of sustainable intersectoral agricultural complexes in macrozones (European part, East), improving the territorial structure of the agro-industrial complex and guaranteeing against the harmful effects of adverse weather conditions;

The transition in light industry from widespread combined production to cluster placement of highly specialized enterprises in compact areas of cities and regions with the cooperation of main industries (several spinning and weaving factories with central finishing production, etc.) production associations. This improves the utilization of labor resources in small and medium-sized cities and provides other economic benefits.

Factors for the location of light industry. The location of light industry enterprises is influenced by various factors: at the stage of primary processing of raw materials, production gravitates toward raw material bases, which is why wool-washing factories were built in the North Caucasus, and flax-processing factories in the west and north-west of Russia. The footwear and apparel industries are positioned with a consumer focus. Industries with a simultaneous focus on both raw materials and consumers include the cotton, wool, silk and knitting industries.

Slide 11 from the presentation "Light and food industry of Russia". The size of the archive with the presentation is 6441 KB.Economics 9th grade

summary other presentations“Branches of food and light industry” - Sewing. Both are correct. Murmansk and Astrakhan. Barnaul. Bakery - yes, sugar - no. 4. Which industry's placement is not consumer-oriented? Koryazhma. Electric power. Ivanovo. Vologda. Butter factory. 5. Industries for the primary processing of flax are located taking into account the factor: Raw materials. Primorsky and Khabarovsk territories.

“Ferrous and non-ferrous metallurgy” - Gave us space for good. Gold, Tin, Lead... Orlov Serezha. Non-ferrous metallurgy: Ferrous and non-ferrous metallurgy. Metal production is an integral part of the Russian economy. Metallurgical complex- a set of industries producing a variety of metals. The main objective of the presentation:

“Agro-industrial complex, grade 9” - Completed by a student of grade 9 M, Ekaterina Gruzdova. Food industry. Composition of the agro-industrial complex. Agro-industrial complex. Target: (Apk). . Study the features of the agro-industrial complex. What is APK?

"Chemical forest industry" - European North. Consumer. Republic of Kalmykia. Brotherly. 06/07/2012. 3. What does not apply to basic chemistry? Komi Republic. Chemical-forest complex. Fertilizer production. Siberian. Energy. Production of pulp and paper. 7. Which of the listed timber processing complexes is not located in the Siberian base? 4. Which factor does not influence the location of organic synthesis chemistry enterprises? Volga-Uralskaya.

"Mining and chemical industry" - Non-ferrous metals. 1. Metallic minerals. 2. Non-metallic minerals. Pyrite FeS2. Pentlandite (Fe,Ni)9S8. Municipal educational institution Secondary school No. 4. Sphene CaTiO (SiO4). Apatite Ca5(PO4)3(F,OH). A.S. Pushkin. Eudialyte Na4Ca2Zr(Si3O9). Ferrous metals. And experience, the son of difficult mistakes, And genius, the friend of paradoxes! Pyrrhotite Fe8 S9. Industrial raw materials. Platinum. Noble metals. Oh, how many wonderful discoveries the spirit of enlightenment is preparing for us!

“Russia in the global economy” - Determine the most optimal one. The cores of the information stage have been formed (Moscow, St. Petersburg). Target - high quality goods and services. Periphery - the poorest countries: Environmental degradation. Wealth in natural resources. Show Russia's place in the world economy. Reveal the ways of development of the Russian economy. Resource-saving technologies. Lesson objectives.

Under easy industry refers to a set of industries producing consumer goods. Light industry provides a full cycle of goods, starting from work on the extraction of primary raw materials and ending with the sale of finished products. The main task of the light industry is to ensure such a supply of consumer products that could satisfy the growing demand for them.

Sectoral composition of light industry

The following groups of industries are usually classified as light industry:

Thus, raw material production includes, for example, cotton mining and hide processing, semi-product production includes textile and spinning work, and final product production includes the production of carpets, shoes, and other things. Currently, there is a clearly noticeable emphasis on the latter group (this is especially true in the clothing and footwear industries), since the sale of finished products brings in much more than the extraction of raw materials for it.

Features of light industry

Light industry has a number of specific features:

- 1. Enterprises of the first category (production of raw materials) must be located in close proximity to the source of raw materials.

- 2. A product can go through each stage at different enterprises - one factory, as a rule, does not transform raw materials into finished product(that is, full cycle implementation).

- 3. Finishing stages are of utmost importance - for light industry products appearance is of great importance.

- 4. The workforce has special requirements, such as taste.

- 5. Light industry enterprises are usually small, and most of them are women.

Regarding the light industry sectors, it should be noted that they are dynamic - the range of final products changes very quickly and is determined by fashion and consumer tastes.

Factors for locating light industry enterprises

Experts do not have a unanimous opinion regarding the factors for locating light industry enterprises, however, among the wide variety, the following main ones can be identified:

- 1. Raw materials. This factor is related to the first of the features listed above. Light industry must be able to provide itself with raw materials, so geographic location is important for such organizations. For example, leather processing factories are located next to meat processing plants.

- 2. Population (aka consumer). The enterprise must be located in the geographic area where there will be demand for its products.

- 3. Labor resources . The enterprise must provide Where it will source labor with the required qualifications before selecting a location.

Light industry in Russia, its weaknesses

A quantitative analysis of the state of light industry in Russia can be carried out using such an indicator as the contribution of pharmaceutical products to Russia’s GDP. A very rapid decline in light industry was evident in the 1990s, when international, and therefore cheap, opened up for the country. Domestic manufacturers turned out to be uncompetitive compared to foreign ones (in particular, China). Thus, during the 90s, the contribution to GDP fell from 11.9% to 1.4%.

Dynamics general development The light industry will be able to reflect the growth dynamics of the systemically important industry, namely textile production:

Despite the fact that the dynamics are positive, there should be concern that the products domestic producers in the total turnover of light industry in Russia only 20% (according to Rosstat). The factors hindering the development of domestic light industry are the following:

- 1. Low wages, unattractive to young professionals.

- 2. High proportion of outdated equipment. At the moment, more than 50% of all equipment used in the domestic light industry has been in operation for over 10 years. It is worth emulating developed countries, where this figure does not rise above 15%.

- 3. Lack of funds. Light industry enterprises are mainly small provincial factories that simply do not have the funds for development and expansion.

- 4. . In each of the main sectors of light industry there is a strong player that occupies a market share of more than ¼ - it is not advisable for new players to fight against it. In the clothing industry, such a company is Gloria Jeans, in the textile industry - Russian Textile.

Stay up to date with everyone important events United Traders - subscribe to our