Radial drilling machine - features and specific models. Radial drilling machines What is a radial drilling machine

Radially- drilling machines are used for processing workpieces of large weight and dimensions in single and small-scale production: in repair production, shipbuilding and mechanical engineering.

Radial drilling Jet machine JRD-1600W

The main advantage of vertical drilling machines is the ability to process parts at any point without reinstalling them. This saves time and increases accuracy, because... Reinstalling a large and heavy part is a time-consuming undertaking and may disrupt its alignment. Those. It is not the workpiece that moves, but the spindle relative to the workpiece.

On radial drilling machines, you can perform standard drilling operations for machining parts, and by equipping the equipment with special tools and equipment, you can bore or grind holes. They are universal.

Designation

According to the classification, ENIMS are designated as follows: the first number in the marking indicates the group “Drilling and boring machines”, the second - the type - “Radial drilling machines”, the third and fourth - the maximum drilling diameter. Letter – the machine was modernized. For example, 2B56 is a radial drilling machine with a maximum drilling diameter of 60 mm.

Modern imported models of machine tools do not have a designation standard - each manufacturer designates models according to its own standard. For example, Optimum classifies its radial machines into light (RB) and heavy (DR): RB6, RB8, DR5, DR6; Proma stands for heavy machine RV-32; Jet – JRD: JRD-460, JRD-720R, JRD-1100R.

The lack of a standard leads to confusion and complicates the selection of analogues.

Layout

The equipment has a unique layout: a column and a table are installed on a stove. A traverse is attached to the column, moving along the column in a vertical position, and it also has the ability to rotate relative to the column by 360 degrees. A drilling (spindle) head is installed on the traverse, moving relative to the traverse in the horizontal direction. It is designed as a separate unit. If it needs to be fixed in a certain position, then there is a clamping mechanism for this purpose.

On the market you can find desktop radial drilling machines that are similar in layout to vertical drilling machines. Their main difference from the classic layout is the ability to move the table in the vertical direction instead of moving the traverse.

Example kinematic scheme radial drilling machine 2N55

The machines have a wide range of rotation speeds, drilling head speeds and mechanical feeds.

Brands

Today, Soviet equipment is being replaced by imported analogues. The main importers are China, Türkiye, Italy and Germany.

Optimum, Proma, Jet, Knuth have won a good reputation among manufacturers.

You can meet them both at large enterprises and small-scale production. This type of equipment is currently the most popular in industry. One of the most common models of this group today is 2M55.Radial drilling machineit is very productive, reliable and durable.

Design Features

Let's look at the specific characteristics of the 2M55 machines below. First, let's figure out what radial drilling units are. Such machines belong to the group of universal type machines. Their main design features are:

large spindle speed range;

the presence of an automatic shutdown mechanism when the specified drilling depth is reached.

Some types of radial drilling equipment may have other design features that increase ease of use. In any case, to The gearbox for speeds and working gears in such machines is located in the drill headstock. Accordingly, all the main components in equipment of this type are located here.

Main structural elements of 2M55

The actual diagram of the 2M55 radial drilling machine includes the following large components:

foundedno;

column;

drillingwowheadat;

traversesu.

The base of the unit is used to fix the workpieces.

Modern industry produces radial drilling machines of various configurations:

stationary desktop;

with a column moving along the surface of the workpiece;

large machines moving on rails;

mounted directly on the workpiece itself near the surface to be processed.

Model 2M55 belongs to the first type of equipment. The layout of the machine part is two-column. This design gives the operator a lot of advantages when working. The fact is that on type machines it is impossible to shift the spindle when clamping the column. That is, the design of the unit is as rigid as possible. This, in turn, among other things, makes it possible to process workpieces with very high quality.

Column clamp of radial drilling machine 2M55(a drawing of it indicating the elements is presented below) a hydraulic one is provided.It is located in the gear housing of the hose lifting mechanism.

St.Erlil grandmaradial drillingmachine2M55 consistsfrom gearboxes and gearboxes. The working tool in such equipment rotates from an electric motor. It is installed, as in all other types of machines, in the spindle. The mounting hole of the latter has a cone-shaped shape.

Scope of use

More oftenradial drilling machines2M55(photo of these unitspresented on the page)can be seen in the workshops of metallurgy enterprises. They are used in most cases to work with large parts. For the same purpose, similar equipment is often used in heavy equipment enterprises.mechanical engineering, shipbuilding and aircraft construction. Such machines, despite the fact that they are essentially an outdated model, are quite expensive and at the same time are distinguished by large dimensions and weight. An enterprise can buy a used 2M55 unit at a price of 150 thousand rubles. This figure is, of course, quite large. However, the price of modern new models of radial drilling machines can reach up to a million or more. Therefore, the 2M55 is very suitable as an economical version of such equipment.

What work can be performed

Be usedradial drilling machines2M55 can for:

creating holes (not only in metal, but also in wood or plastic);

countersinking and drilling;

grinding surfaces;

creating threads inside holes.

Equipment of this type is intended for both roughing and finishing of internal conical, cylindrical, threaded or end surfaces. The following working tools can be used on such machines:

drills;

taps;

scans.

Also, in some cases, various kinds of special tools may be used.

Main technical characteristics of the radial drilling machine 2M55

This model is currently used most often in enterprises.Equipment used2M55, as already mentioned, mainly for processing large parts. Therefore, one of the featuresmodels, like most other radial drilling machines,is high power.Processing of workpieces on such a machine can be carried out at 19 different speeds. Such equipment may be used for different materials. However, most often metal workpieces are processed on radial drilling machines. The largest drilling diameter in 2M55 units on products made of medium-hard steel is 50 mm.

Other characteristics of 2M55

In operation, the 2M55 radial drilling machine, the description of which was given above, as you can see, is quite convenient. This is determined primarily, of course, by its excellent technical characteristics.

Technical hacharacteristics of radial drilling machine 2M55,thus, it has very good ones. This model is equipped witha control system that makes it easy to automate any operation performed.

Of course, it comes complete withradial drilling machine 2M55 and passport.From this document you can learn more about the characteristics of the unit. Also included with the passport are instructions for operating this equipment and safety rules when working on it.

Advantages of the model

In comparison with previously produced modifications, the 2M55 machine has the following advantages:

the presence of a developed cone that allows you to work at high temperatures;

increased hose stroke along the column;

speed of movement of the clamp and sleeve (reduces reinstallation time);

excellent maintainability;

absence of various types of mechanisms on the upper end (provides ease of use).

Manufacturer

Since Soviet times, the 2M55 model has been produced by the Odessa Radial Drilling Machines Plant. This company was founded in the century before last - in 1884. IN Soviet times it was called the Lenin Machine-Building Plant. This company began producing machines back in 1928.

The first radial drilling unit, designed to make holes with a diameter of up to 50 mm, was manufactured by the plant in 1946 - immediately after the war. In addition to the popular 2M55 model, this company supplies Russian and Ukrainian markets such high-quality units, well known to many manufacturers, such as 2A55, 2N55, 2A554, etc. Some machines from this manufacturer are designed for drilling holes up to 75 or even 100 mm in diameter. Any machines from the Odessa plant are considered by consumers to be very high quality and reliable products. This also applies, of course, to the 2M55 model.

Radial drilling equipment 2M55 with CNC

To increase the performance of units of this brandimproving the quality of parts processing at metallurgical enterprises and machine-building plants in addition to them, CNC can be used. INmodificationsCNC(for example, machine 2M55F2) software usually based on movement along three axes, tool number andto the processing mode parameters. In this case, the workpiece can be installed on a table-slab or on the foundation of the unit. The operator changes tools manually.

To ensure smooth operation of the CNC radial drilling machine2M55A rack for 18 tools is usually installed next to it. Each cell of the latter is equipped with a light indicating the order of installation in the spindle. Switches are also mounted here to control the order in which the tools are used.

Modern modifications

The 2M55 model was developed, as already mentioned, back in Soviet times. At that time, this unit was considered innovative equipment. Modern manufacturers also consider the 2M55 to be quite reliable and durable. These machines rarely break down. At the same time, it is very convenient to work for them. But still, this unit is, of course, inferior to modern radial drilling machines in many respects. The 2M55 modification and the addition of CNC can significantly increase its productivity and improve the quality of workpiece processing. However, enterprises still purchase such machines mainly only if they want to save money for some reason.

If the priority task of the plant is to produce high-quality parts in large quantities, its management should, of course, pay attention to more modern views radial drilling equipment. Such modifications of 2M55 include, for example, machines:

2S550;

2K550;

AC2550.

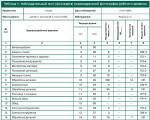

Their technical characteristics, for comparison withradial drilling machine2M55,are presented in the table.

Is it being released today?

Despite the fact that engineers have recently developed new, more advanced modifications of the 2M55 machine, its production continues to this day. Many companies supply this equipment to the market and purchase it if necessary. special labor will not amount to. In most cases, the manufacturer of these units provides a 12-month warranty on their products. If necessary, enterprises have the opportunity to order the modernization of the 2M55 machine from almost any plant that produces radial drilling equipment.

The radial drilling machine is one of the rather complex devices that ensures a high level of quality of the work performed. It is necessary for creating a variety of holes and internal threads, drilling and countersinking. Working on a conventional machine requires the operator to have experience and certain skills, ability, attention, concentration and significant physical effort. That is why the use of a CNC radial drilling machine has become an excellent replacement for old equipment and a guarantee of performing work with high precision.

Unit features

The use of a radial drilling machine allows you to speed up the execution of various operations related to the creation of various types of holes in parts made of metal. This is a universal equipment that, despite its small size and ease of maintenance, allows you to achieve a high level of quality when performing operations related to drilling.

CNC equipment is designed to create through or blind holes in metal workpieces and parts. The main components of the machine are:

- thread taps;

- drills of various diameters;

- sweeps;

- countersink.

In addition to the listed elements, the machine can be installed additional equipment. However, the presence of numerical program control involves the use of a special computer unit, into the memory of which all the nuances of the upcoming planned operation are entered.

The peculiarity of radial drilling machines is the ability to make the required holes at any angle to the surface of the part. In this case, the appearance of each individual hole depends on the angle of its axis.

All necessary data is entered into the computer’s memory and the planned operation can be performed at a high level of quality and without the use of manual operator labor.

Thanks to the design features of the machine, which the developers took care of, parts with complex geometry and non-standard parameters can be processed.

The holes processed on this machine have a cylindrical or even conical shape. All parts are securely fixed, and tools designed for cutting metal move smoothly in a given direction.

CNC radial drilling machines can be large or small and mounted on a workbench. In any case, they all differ in characteristics, which allows them to work with parts made from a wide variety of metals.

Structural units

There are 4 types of radial drilling machines, differing in their design features and the presence of certain components in the design:

- Stationary equipment on which general operations are performed.

- Equipment equipped with a column, the peculiarity of which is the ability to move along guides installed here along the surface of the workpiece.

- Machines that are particularly large in size move themselves in a given direction. The guides for these models are specially mounted rails.

- Small-sized machines installed in the work area. They are designed to perform high precision operations.

Working on a machine equipped with numerical control requires special training and availability large quantity knowledge and skills.

Working with numerical control requires certain skills and abilities.

Despite the presence of some design features, each model is equipped with a base characterized by a high degree of reliability.

The part is fixed on it. The cylindrical column of the radial drilling machine, on which the horizontal traverse is fixed, is made in such a way that it can perform rotational movements.

The traverse moves in a horizontal plane, but to perform drilling operations or creating internal threads, it is necessary that the machine is equipped with a drill headstock with a working spindle. It is the spindle that is necessary for reliable fixation of the metal carving tool.

This design is quite simple and the specified work on stationary equipment is carried out in short terms With minimum cost physical strength.

CNC drilling

How does the unit work?

The functionality of a radial drilling machine depends on the quality of its components. For example, the operation of this equipment requires the installation of a gearbox in the drill headstock and adjustment of the working gears.

All manipulations associated with the processing of metal parts are performed thanks to the precise and rhythmic rotation of the cutting tool.

On the front panel there is a kind of control center for the machine and all operations performed. Its power also depends on the quality and features of the electric motor with which the radial drilling machine is equipped. However, the parameters of the processing performed depend on various factors, including:

- diameter of the hole being created;

- the greatest distance that the spindle can move;

- the number of the cone, which is located in the inside of the spindle and attached to the machine;

- the number of steps with which you can adjust the spindle speed;

- number of spindle revolutions.

Radial drilling machines are complex, but highly efficient and multifunctional equipment.

Most of these machines are used on large enterprises, and numerical control greatly facilitates the work performed on creating different diameter holes in parts of the most complex shapes.

Advantages of CNC machine

Main feature radial drilling machine with numerical control – lightness and high processing speed. This is possible thanks to the availability of a complex of equipment, which includes the following systems:

- hydraulic;

- mechanical;

- electric.

Various metals are used to create machines. It can be cast iron or high strength steel. The process of creating equipment requires the use of materials that have undergone special processing.

The filler machine is designed to create both through and blind holes. And equipping it with numerical control allows you to significantly speed up the production process without reducing the level of accuracy of the operations performed.

Modern radial drilling machines equipped with numerical control are reliable, ultra-precise, durable, multifunctional equipment.

Advantages of the CNC system

Many machine models have increased the size of the working plate, increased the number of working gears and built-in spindle speeds.

Everything has a huge positive impact on labor productivity, and the CNC unit makes it much easier to control the machine. It is also important how well the cooling system is equipped. For this purpose, the units are equipped with powerful pump motors.

When creating a CNC machine, several schemes were used to ensure effective management and control production process. For example, vertical movement is controlled thanks to the presence of stops and switches, recording a program on punched tape or typing a program on a plug panel.

Today, CNC machines, which have a more complex design, are widely used in production. Their column is capable of performing a complete rotation around its axis, and the working head is mounted on a traverse that can move vertically.

This proves that modern equipment equipped with numerical control not only simplifies routine operations, but also guarantees a high level of quality of the created parts.

Video: Radial drilling machine

Radial drilling machine: popular modifications and types. A radial drilling machine allows you to perform a much wider range of tasks than a conventional vertical drilling machine. But which ones are the most best models such machines? Review of the best modifications.

A radial drilling machine differs from that in that the bed with the drill moves in different planes relative to the workpiece, and not vice versa.

This is due to the fact that many workpieces are large and are inconvenient to fix on the object table. Thanks to this work scheme, not only productivity increases, but it is also much more convenient to implement various flow production technologies. However, we must take into account that not all radial drilling machines are easy to use. So, what are the best models of such machines that you can buy in Russia today?

Belarusian radial drilling machines

Belarusian radial drilling machines of the GS544, 2K550, 2K552, GS545, 2K550V brands, which can be purchased at a minimal price and without customs clearance, are in great demand. They are cheap, their frames are reliable, the weight range is from 950 kg to 3.5 tons, the power is from 1.5 to 4 kW.

Radial drilling machine GS544

These machines have everything you need. In the GS series, the drilling head rotates at any angle, many models have the ability to supply coolant, in general, these, although not very functional, are very worthy products that can meet the minimum production needs. They drill holes up to 60 mm, which allows them to be used in almost any field. Of course, reviews for radial drilling machines made in Belarus are not always full of positive ratings, but this applies to all budget equipment. The price for these models starts from 1 million rubles - for professional equipment in this category this is very, very little.

In conditions, Belarusian machines will become quite widespread, unless, of course, relations between the countries deteriorate. Judging by latest news, supplies of equipment from Belarus may well begin to be subject to duties.

Russian radial drilling machines

The most popular model of a Russian-made radial drilling machine is, of course, the Soviet model 2A554. Also, the 2M55 machine has always been very popular. Today, these models have many competitors - in particular, the AC2250 model, which can be bought for only 950,000 rubles, is actively replacing it. There are also cheaper modifications, for example, the price for the AC2532 radial drilling machine is about 520,000 rubles. For the average performance model AC2540 – 630,000 rubles. All this is very cheap.

Radial drilling machine AC2250

What is interesting about Russian radial drilling machines. They do not compete, for example, with Belarusian models. They occupy a separate niche. For example, their spindle speed adjustment is stepless. The maximum hole diameter is up to 40 mm. But they do not differ in weight and power - Russian machines also have 1.2 and 4 kW of power, the weight reaches 3.5 tons.

But in terms of technology, the Belarusian manufacturer has gone somewhat ahead. Still, Belarusian devices are more universal, especially for the GS series. But Russian equipment is much cheaper. As for quality, it is approximately at the same level - slightly higher than Soviet.

Ukrainian radial drilling machines

Ukrainian radial drilling machines are in great demand in Russia, primarily due to the fact that the 2A554 machine with a stepped transmission is still produced in Ukraine. Moreover, what is interesting is that Ukrainian machines are significantly superior in quality to Russian and Belarusian ones. Therefore, when entrepreneurs decide to buy a 2A554 radial drilling machine for continuous production, even if they overpay for delivery and customs procedures, they can be understood - they just want many years of trouble-free operation. This machine is made at the Odessa Radial Drilling Machines Plant, where machine-building equipment was riveted 100 years ago. The plant is fully engaged in these types of machines, it has managed to retain the accumulated experience, and therefore the quality of the equipment is not bad.

Radial drilling machine 2A554

Ukrainian radial drilling machines also occupy their niche in the market. In addition to the 2A554 model, ultra-high power machines are made in Odessa. Thus, model 2A576 produces 7.5 kW, weighs more than 11 tons and can drill holes up to 100 mm. But there is even more powerful model 2A587, which drills holes up to 125 mm, weighs about 17 tons and produces 11 kW of power. Both modifications have continuously variable

transmission and excellent hydraulics.

Chinese radial drilling machines

Chinese radial drilling machines are very common. For example, the manufacturer SMTCL supplies Russian market two very attractive models - Z3050x16 and Z3040, which can be purchased at a price of 940,000 rubles. These are very interesting 3-kilowatt modifications with a lot of functions that can drill holes up to 50 mm. The spindle rotation is adjusted in steps and has 16 speeds.

Radial drilling machine SMTCL Z3040

The models are very functional and easy to use, consume little electricity, and operate quite quietly.

The manufacturer claims that Chinese radial drilling machines are made from hardened metal alloys, but domestic consumers have some doubts about this. In principle, if you do not overload the machine, it will most likely last quite a long time. But is the declared 3 kW of power enough for serious metal processing, especially with a diameter of 5 cm?

Radial drilling machine MRD32x7 from Weiss Machinery

Weiss Machinery is a very popular company among Chinese radial drilling machines. For example, for its model MRD32x7 the price is only 130,000 rubles. And this is a very high-quality 1.1-kilowatt machine, capable of drilling up to 32 mm. This manufacturer also has more powerful models MRD50x16, MRD40x10, the reviews of which are very positive. Although, of course, compared to Ukrainian, Russian and Belarusian machines, these models look very flimsy.

By the way, in China they produce machines under the Czech brand PROMA and the Swiss brand JET. Externally and functionally they are not much different from Weiss Machinery and SMTCL. In many cases electrical diagram The radial drilling machine used by these manufacturers is the same. But, according to managers, quality control is higher there.

To summarize, it can be noted that Belarusian and Ukrainian machines are more proven, as well as for mass production. However, Chinese manufacturers offer cheaper, more functional and economical models suitable for small industries.

The Odessa RCT plant manufactures radial drilling machines of the 2A554 series. This type of equipment is designed for processing large workpieces, the movement of which along the surface of the worktable is difficult. The design of the machine provides maximum access to all edges of the part and allows you to perform a wide range of operations.

Machine design

The main purpose of the 2A554 machine is to form holes by drilling, countersinking and trimming ends. The spindle head has several degrees of freedom and moves relative to the workpiece.

The main difference from similar models is the concentration of the main controls in the design of the drilling head. It is located on the sleeve, which is fixed to the axis of the vertical column. This ensures displacement of the drilling unit both vertically and horizontally. An advanced control system allows for maximum automation of the processing process.

The 2A554 radial drilling machine has the following components and assemblies:

- base plate, which has several T-shaped grooves for securely fixing the part;

- a column rotating around its axis. To perform this function, it is provided with bearings;

- a sleeve attached to a column;

- drill head. It moves along the guide sleeves in a horizontal direction.

For the operation of units and components, the machine design has hydraulic clamps that provide fairly easy position changes. The controls are located on the side of the drill head, making it easy to set up the equipment. It is also possible to pre-set operating modes and frequency. This feature improves productivity and accuracy of workpiece processing.

Regardless of the location of the spindle, it will always be balanced. Thanks to this, the range of operations performed, degrees of processing of the part, is expanded.

Equipment technical parameters

The competent layout of the 2A554 machine made it possible to achieve optimal performance. This directly affected the characteristics of the equipment. Their review should begin with the main parameters. The weight of the machine is 4700 kg, its dimensions are 266.5 * 103 * 343 cm.

The accuracy class of the equipment corresponds to “N”. The maximum permissible drilling diameter for steel 45 is 50 mm. It is also possible to form holes in cast iron blanks. Their diameter cannot exceed 63 mm. The spindle can move along the hose at a distance from 35 to 160 cm. The maximum height of the hose lift along the column is 75 cm. In this case, the maximum speed is 1.4 m/min.

The dimensions of the desktop are 102*255.5 cm. Additionally, it is possible to install additional tools to improve technical and functionality equipment. Its weight cannot exceed 15 kg.

To understand the performance qualities of the 2A554 machine, you should carefully study the parameters of the spindle head:

- sleeve diameter – 9 cm;

- rotation speed limits - from 18 to 2000 rpm;

- the number of speeds is 24;

- limits of working feeds that are possible with one spindle revolution – from 0.045 to 5 mm/rev;

- thread formation parameters. Feed limits per revolution - from 1 to 5 mm;

- maximum torque, kgf*cm – 7100;

- permissible feed force, kN – 20.

To control the position of the working head, there are several types of clamps in the design. When the column rotates and the drilling head moves along the sleeve, hydraulic devices are used. Clamping of the sleeve on the column stand is carried out using electric clamps.

The main drive of the 2A554 machine is performed by an electric motor with a power of 5.5 kW. To move along the hose, the design includes a 2.2 kW electrical installation. Additional devices (5 pcs) are designed to supply coolant and ensure reliable fixation of machine components relative to each other.

To turn off the spindle and change the direction of its rotation, the machine has a friction clutch. It is located between the gearbox and the main electric motor.

Before final installation of the 2A554 machine, you should prepare a working platform for it. It is best to equip a special platform that will be able to support the weight of the equipment. Then you need to check the components and assemblies for hidden and obvious defects.

After installation, connection to the electrical network is carried out. It must be designed for the maximum power of the equipment. Therefore, it is important to study all the characteristics of the machine, changing parameters depending on the current operating modes.

In addition, during operation of the equipment the following factors should be taken into account:

- when emergency situations(breakdown or malfunction) first a complete shutdown is performed and only then repair work is carried out;

- While the equipment is operating, it is prohibited to clean it, change the position of the workpiece, or tighten the bolts and nuts of the structure;

- If drain chips form, the drill should be removed from the hole. Otherwise, there is a high probability of long chips forming. It can stick to the cutting edges of the drill or the ends of the surfaces being processed;

- control the functionality of the counterweight, which is necessary to adjust the position of the spindle.

The operating personnel must be given safety instructions and the characteristics of the machine are studied in detail.

The video shows an example of the operation of the 2A554 machine: