Do-it-yourself water heating in a greenhouse. How to properly heat a greenhouse with your own hands. Stove heating of a greenhouse

1.

2.

3.

4.

5.

6.

Heated greenhouses make it possible to eat vegetables, herbs and fruits all year round. The minimum temperature that must be provided in a greenhouse to grow crops is 18 degrees. To maintain such a temperature regime in it, walls alone are not enough, no matter what material they are made of. You can see what heating devices suitable for a greenhouse look like in the photo.

It would be most economical to build a greenhouse in the place where the heating main runs. In this case, you will only need to find the most suitable place for construction. Otherwise, more attention will have to be paid to the construction of the building. But in both options, a greenhouse heating system is simply necessary.

Heating a greenhouse with gas

Gas system heating greenhouses is quite popular. It is not recommended to supply gas from the house to the greenhouse - it will be too expensive. It is better to buy several gas cylinders - they should be enough for the winter (read: " "). This option will be much more economical. When using such equipment, it should be taken into account that combustion products natural gas do not have the best effect on plants. For this reason, it is necessary to make ventilation and exhaust in the greenhouse to remove them outside.When purchasing a heating device, you should pay attention to the fact that it has a special sensor. It is needed so that if combustion stops, the gas supply to the burner is immediately shut off.

Heating with solid fuel boiler

It is better to install such heating equipment not in the greenhouse itself, but in the vestibule. This option is more preferable for the reason that you do not have to open the door to the room several times a day, letting cold air in to add another portion of fuel. But at the same time, in this case it will be less effective, since the heat also comes from the walls of the boiler itself. It is necessary to correctly calculate the heating of the greenhouse so that the device is powerful enough (read also: " ").The main disadvantage of solid fuel boilers is the need to regularly add fuel. But this problem can also be solved - long-burning devices have recently appeared that can operate on one load of fuel for up to 36 hours. Such boilers are economical and safe to use.

Stove heating

If you heat the greenhouse yourself, then you can significantly reduce your costs. One of the economical ways to heat a greenhouse is to install a stove. A simple design can be made independently, the financial costs in this case will be minimal.

Then an expansion tank with a volume of 20 liters is attached to the barrel - it is welded from sheet metal. A heating system is welded from a profile pipe measuring 40x20x1.5 centimeters. The pipes are laid on the ground so that there is a distance of 120 centimeters between them. This arrangement of pipes will allow the soil to warm up. To ensure water circulation in such a heating system, a special pump will be required.

Water heating

Heating a greenhouse using a water system is more efficient than other methods (read also: " "). It is not difficult to make heated greenhouses with your own hands if you follow the instructions given. The main design element is a water electric heater (read also: "").

The device can be made from a regular fire extinguisher. Its top is cut off, and a heating element with a power of 1 kW is installed at the bottom. The heating element can be taken from a samovar or an old household appliance of the required power. A removable lid is made at the top of the device to pour water into the heater (read also: " "). Two tubes are connected to its body, which are connected to the radiator. The tubes are attached using sealing gaskets and nuts. For the operation of such a heater to be automatic, the heating circuit of the greenhouse must include an AC and 220 V relay.

Heating a greenhouse using solar panels

The greenhouse can also be heated with devices that absorb solar rays.To create such a heating system:

- first they dig a hole about 15 centimeters deep;

- then a layer of polystyrene or any other heat-insulating material is laid on the ground;

- a plastic film is placed on top to provide waterproofing;

- Wet sand and soil are poured onto the film on top.

This system is very simple and does not require financial costs, but it is quite suitable for maintaining the temperature in the greenhouse that is optimal for plant growth. In this case, there must be special devices on the roof that will absorb solar energy and thereby help heat the greenhouse. It is worth considering that in winter such a system will be ineffective - on cloudy days the greenhouse will not be able to warm up (read also: " ").

You also need to calculate the heating for the greenhouse so that it is efficient.

Heating a greenhouse with your own hands, see details in the video:

Air heating

This method is also quite simple, and it does not require financial costs. First, take a piece of iron pipe 2-2.5 meters long and 50-60 centimeters in diameter. Then one end of the pipe is inserted into the greenhouse, and a fire is lit under the other. The air in the pipe will warm up quite quickly. This method is quite suitable for maintaining a comfortable temperature in a greenhouse.The main disadvantage of this heating method is that the fire must be constantly maintained. If the fire goes out, the temperature in the greenhouse will drop very quickly. Therefore, such heating of a greenhouse is not common. Read also: "How to heat a greenhouse - possible options."

It is difficult to say which heating is best for a greenhouse. Currently, there are many ways to heat greenhouses, each of which has its own advantages and disadvantages. For example, heating using electrical equipment is highly efficient; its operation does not need to be constantly monitored. But at the same time, such a heating system will require significant financial investments, and operation will be expensive. Inexpensive systems require constant monitoring. Therefore, the choice of heating option for a greenhouse depends on many factors, among which financial capabilities are of considerable importance.

The word greenhouse itself hints directly and unambiguously: it should be warm there. But gloomy autumn or spring weather, short daylight hours, rains and melting snow, piercing winds, damp and cold soil - all this prevents it from living up to its name. This is why it is so important to take care of additional heat generation.

Peculiarities

Heating a greenhouse is fundamentally different from generating thermal energy for a private house, bathhouse or garage. There are many more options, and therefore it is extremely important to understand all their features. Most systems for heating greenhouses in winter can be done with your own hands. But it’s important to remember that you won’t be able to control the heating as carefully as you would at home - you can’t “live” in a greenhouse. That is why it is so important to create not just a powerful system, but one that eliminates temperature fluctuations.

When choosing the best option, pay attention to:

- energy efficiency;

- fire safety;

- formation of an optimal microclimate for plants;

- ease of installation and operation;

- system reliability.

Pros and cons of methods

There are many options for heating greenhouses. Let's look at each of them in more detail.

Electrical

The rising cost of all types of fuel is a trend that will continue for years and even decades to come. Therefore, among the electrical methods of heating greenhouses, it is the film options that have a clear priority. The thinnest (layer from 0.04 cm) film is a selection of current-passing strips, which are laid according to a special pattern.

Its advantages are:

- possibility of fixing on any solid base;

- ease of connection to the electrical network;

- safety of use;

- excellent efficiency.

In terms of weaknesses, the minimum film thickness is the primary drawback. A small footprint results in a high risk of damage. Errors when using infrared coatings may result in the need to call the Ministry of Emergency Situations.

A more mechanically resistant option is a heating cable. It is capable of operating for 20 years in a row, the system is activated both over a large area and in isolated areas.

Cable circuits in the “warm floor” format are best choice compared to water systems. To switch equipment from general heating to local heating, you only need to perform 1 action with the simplest control device. The classic resistive cable is simple and inexpensive; the type of insulating sheath and external mechanical protection determines the period of operation.

A cable with one core will have to be placed so that both ends are near the power source. There is only one alternative - an additional cable for connecting the far end.

Resistive cables can adjust the amount of heat generated to the warming of the ground. But even in two adjacent beds, the actual temperature of the ground can vary quite significantly. Therefore, you have to either configure everything “one size fits all” or create complex, expensive systems. Self-regulating cables are considered more modern, further saving current. Individual segments tailor heat output to a specific task; if a certain fragment is already warmed up, the cable will not work there.

However, there is another option - using heating panels.

The panel method of heating greenhouses allows the installation of basic systems both near the ceiling and in the walls. The electric version of the panels works well if the greenhouse area is limited to 25 m2. In larger spaces they are not economical enough. You will need to lay out a serious cable route and waste a lot of energy. In addition, in many dacha communities and suburban settlements, the amount of current consumed per household is limited.

Speaking about heating with electricity, we cannot ignore such an option as a carbon cord. Compared to other cables, it has thermal inertia (it is equal to 0), eliminates temperature fluctuations and helps to smoothly adjust conditions to emerging needs. The carbon cable is compatible with all known types of thermostats. Even when adjustments to the contour length are required, this is done very easily and simply.

A heat gun also has its advantages.

All electrical systems make it possible to do without such an element as a chimney pipe, but the “gun” is simpler in design than others. The need for additional devices is completely eliminated. Commissioning takes place immediately after purchase

Sunny

Heating from the sun is considered the most natural solution, and modern methods allow it to be used both in a winter greenhouse and during the dark period of the day. It is imperative to create a greenhouse made of polycarbonate or glass. But you will have to form the structure in the form of an arch and maintain an orientation from east to west. To compensate for the short daylight hours, the greenhouse is equipped with a solar collector. It is formed in the form of insulated trenches, over which coarse sand is poured, and an additional layer of soil is created.

If you compare such a scheme with air heating, it becomes clear that even adding improvised batteries does not increase efficiency enough. The supply of heated air provides both stronger and faster heating. The only problem is that a lot of fuel will be consumed during the harsh winter.

Biofuel

Since ancient times, farmers have used manure and a number of other organic substances to heat the soil. When organic matter decomposes, a significant amount of heat is released. In many cases, preference is given to horse manure, which reaches 70 degrees within a week and maintains this level for months to come. If there is no such significant need, a combination with straw is used. You can also mix manure with tree bark, sawdust and kitchen waste.

The disadvantages of biological fuel are:

- subjective discomfort;

- risk of poor hygiene;

- unsuitable for heating for more than 4 months in a row.

Gas

In many country houses and country houses trying to establish gas stoves. And this suggests another way to correct the shortcomings of the greenhouse. The relative cost-effectiveness and simplicity of the system, the ability to create it from factory components - these are the main positive aspects. However, along with accurate calculations, you will have to prepare drawings and a package of permits. Without the consent of the registering parties government agencies it is impossible to implement the project, and each rework entails new costs.

Natural gas is flammable, explosive and toxic. When using it, the greenhouse becomes an excessively humid place, and the concentration of carbon dioxide increases excessively. The oxygen saturation of the air is additionally reduced. Installing ventilation further complicates the matter and requires additional calculations, and in winter the supply of fresh air depreciates the energy generated.

To reduce a little the cost of using gas, a monorail type of water heating is practiced (with the connection of a coiled pipeline to the pump).

Advantages of water

It is good to heat a greenhouse with water heating because this option allows you to transfer heat to both the ground and the air.

Device

Unlike solar heat generation, large rooms can be heated year-round. What is important is that the appearance of dry air is completely eliminated. But ventilation becomes critically important, since air stillness can lead to overheating of plants.

If you use the classic air scheme, it is technically simpler, but it consumes more energy and achieves an identical result at a noticeably higher cost.

Boiler selection

Worth paying attention the right choice boiler so that it satisfactorily performs its assigned tasks. In greenhouses, it is practiced to install the same heating means as in houses and other buildings.

Greenhouse boilers can operate on:

- wood processing industry waste;

- quality firewood;

- hard and brown coal;

- peat;

- household flammable rubbish;

- natural and liquefied gas;

- diesel fuel.

Largely selection suitable system determined by personal taste and the range of available energy sources. If the area has main gas pipelines, it is best to connect to them. Even bureaucratic bastions do not detract from the efficiency of “blue fuel”.

Boilers running on electricity or solid fuel can also be used. It is necessary to carefully select the overall power of the configuration so as not to freeze the plantings and pay only for the heat that is really needed.

System installation

In addition to the boiler itself, you will also have to install pipelines and radiators associated with them. The role of expansion tanks, chimneys and pumps that maintain circulation is great. Experts recommend forming a pair of heating circuits, not just one. One line is installed underground, which is made of plastic pipes that serve to migrate water with a temperature of approximately +30 degrees. Such pipes must be laid as close to the roots as possible.

The second tier is located under the dome and is made using radiators. Most often, forced pump circulation is used in greenhouses; gravitational flow of water is used much less frequently.

It is useful to supplement the heating circuit with thermal regulators, which allow you to control the operation of the system automatically. There will be no need to worry that if you are absent for a long time, the greenhouse will overheat or overcool. Radiators in greenhouses are made of cast iron, aluminum or bimetallic.

Please note: there are systems that do not have radiators at all. Then the space under the dome is heated using a round steel pipe of significant cross-section. Expansion tanks are made either open or closed, but without them, unlike radiators, the system cannot be installed. You can save money when you don’t buy expanders, but make them from metal sheets at home. As for the chimney, along with traditional brickwork, it is practiced to create asbestos-cement channels and use steel pipes round or square section.

If possible, it is recommended to take pipes in a sandwich format. This is the most modern and practical solution. As for circulation pumps, here, too, not everything is as simple as most summer residents believe. In budget-class greenhouses, if a pressure difference is ensured, gravity pumping mode can also be used. Again, the choice of components is determined primarily by material considerations.

Stoves or heating boilers are mainly installed in the vestibules of greenhouses; much less often they are given a place inside. The advantage of the external location is that the fuel, stacked nearby, does not interfere with movement around the greenhouse and does not create problems during operation. But the internal placement also has its advantage - it helps to obtain additional heat. You need to weigh the pros and cons when assessing the available space. Any boiler and any furnace definitely deserve the installation of a foundation.

If the stove is made of brick, a concrete base is poured under it. But it is enough to place metal heat generators on a sheet of steel or asbestos cement. In any case, it is worth taking care of the most reliable installation of the system.

When installing a chimney, care is taken to ensure that any joint or turn is thoroughly sealed. Even the best cement cracks when heated significantly, so it is worth using clay mortar instead.

Connection to the boiler inlet and outlet pipes must be made using steel pipes that are strictly identical in diameter. Only after 1-1.5 m they can be replaced with plastic elements. Expansion tanks are installed in the highest places of buildings near furnaces and boilers. They must be preceded in the hydraulic circuit by an automatic blocking valve, as well as a pressure gauge. When equipping radiators with cut-off valves, the inlet and outlet pipes must be separated by jumpers, then one stopped battery will not paralyze the entire system.

It is recommended to provide soil heating with pipes based on cross-linked polyethylene. It is very good when a circuit that performs a similar task is supplemented with control automation. It must set operating modes that correspond to the specifics of certain plants. The very device of soil heating in greenhouses is quite close to the well-known “warm floor”. Those who have already installed such a floor are unlikely to encounter any particular difficulties.

An insulating layer of waterproof material, most often polystyrene foam, helps to avoid heat loss in the ground. Polyethylene film helps to enhance waterproofing properties. The pipes are laid out on a sand cushion, which was previously washed and compacted after backfilling. The thickness of the pillow should be 100-150 mm, this will ensure uniform heating and zero risk of drying out the soil; 300-350 mm of fertile soil must be placed above the heating layer.

Pechnoe

One of the popular solutions in summer cottages is stove heating of greenhouses, but it also has its pros and cons.

Advantages and disadvantages

Suppliers of all boilers and other heating elements for greenhouse farming place the main emphasis on high efficiency. But modern stoves demonstrate equally impressive efficiency. Therefore, it is naive to consider them frivolous competitors of boiler equipment.

- low cost of heating using solid fuel, wood or waste oil;

- simplicity of the system itself (ease of installation and maintenance);

- wide availability of necessary fuel.

Most often, iron stoves are installed in greenhouses, which quickly warm up, but quickly lose their heat charge. A disadvantage of such devices can be considered their “tendency” to dry out the air. Even for plants that are accustomed to a dry and hot atmosphere, this is unlikely to be beneficial.

The use of water circuits in the form of radiators or registers helps to reduce the severity of temperature fluctuations.

Selection and installation of the furnace

The classic solid fuel stove is in demand mainly in greenhouses used in spring and summer.

Such structures are much more mobile than brick ones and remove the obligation to form a foundation. Another important circumstance is the minimal absorption of usable space. It is worth taking into account such advantages of metal stoves as low cost, possibility of installation with my own hands without mastering the art of bricklaying. As for weaknesses, it is necessary to mention the unsuitability of such stoves for automation. Chimneys diverted from metal stoves should be placed at an angle of at least 15 degrees to enhance heating.

The metal pipe itself must be stripped of any insulation. But at intersections with the top or wall, it is necessary to install a heat-impermeable box. Any steel stove must be installed in such a way that it is completely prevented from falling. Many times such events have caused fires and loss of property.

In regions with harsh weather conditions You can use coal-fired stoves, which produce more heat and retain it longer.

But the problem is the increased amount of waste and increased toxicity of combustion products when using coal fuel. Some of its types are capable of igniting on their own and deserve specific conditions during accumulation. In recent years, the popularity of sawdust stoves or fuel briquettes, which are made standard in design and emit a minimal amount of smoke.

But diesel stoves are not suitable at all. They emit toxic smoke, and the slightest mistake can cause an emergency.

What should you consider when choosing?

Speaking about the most best projects for heating the greenhouse, it is worth noting that this does not include the use of convectors. By themselves, they only heat the air, and the soil layer remains cold, as before the system was turned on. Therefore, you have to take care of biological heating, which is extremely important during frosts in early spring. But there is a better strategy - this is the use of a heating system in the form of mats or cable laying (heating tapes). For winter, such a solution is simply ideal, especially because it allows you to warm only those places that are really needed.

The risk is that the slightest mistake in calculating the required temperature can burn the roots of the plants. Geothermal heating of greenhouses in a small private farm is completely unprofitable, since it requires very large investments in equipment and begins to pay off too late. The use of solar batteries or heating lamps is of an auxiliary nature. The first cope primarily with the effects of cold summer, while others are needed to create optimal conditions for seedlings. Therefore, a serious choice arises only between electric heating (including infrared) and boilers (stoves) on various types fuel.

Popular types

If you need to heat a greenhouse economically and simply without electricity or gas, the choice naturally leans in favor biological method. For gardeners who are accustomed to working in the ground and coming into contact with dirty substances, such heating will not cause much mental anguish. In addition, it is completely environmentally friendly and allows you to heat the beds. In northern latitudes and in places with an unstable, unstable climate regime, heating a greenhouse space can only be done relatively cheaply, because one or another fuel will still have to be consumed. If the area is gasified and the greenhouse area is small, you can power the burners or air heaters from cylinders.

If the heated beds are very large, this method cannot be considered economical. You will have to connect to a centralized heating system for the site or look for other methods. The high cost of electric current, as already mentioned, has a somewhat less impact on the costs of gardeners when choosing a rail circuit. Instead of infrared film or “warm floor”, you can also use water pipes connected to an electric boiler. But here the system becomes more complex, and it is rarely possible to install it without the help of professionals.

For information on water heating in a greenhouse with your own hands, see the following video.

The early harvest is harvested from your greenhouse primarily due to its heating - after all, solar radiation for most plants is sufficient only in the summer months. But maintaining a winter garden or growing fresh vegetables and exotic fruits in severe frosts is impossible without specially equipped heating in a greenhouse, because the minimum temperature that can be in a greenhouse is +18°C. And warm, impenetrable walls alone are not enough here. The most budget option for heating a greenhouse - if under summer cottage plot the heating main passes through. Then all that remains is to find the right place, and the problem of how to make heating in a greenhouse is solved. In all other cases, heating greenhouses will be more difficult, but it is quite possible to do it yourself - the diagrams and tips in this article will be extremely useful for this.

Option #1 – solar batteries

It is possible to heat the greenhouse using solar heat accumulators. First, they dig a 15 cm hole in the greenhouse and cover the ground with a layer of thermal insulation, possibly polystyrene. A layer of plastic film is placed on top for waterproofing.

Then coarse wet sand is placed on top and the whole thing is covered with excavated soil. This simple device allows, using the accumulated energy of the sun, to maintain a satisfactory temperature in the greenhouse even at a temperature of -10°C.

Option #2 - air heating

The easiest way to heat a greenhouse or greenhouse is to equip a primitive air heating:

- Step 1. Take a piece of steel pipe with a diameter of 50-60 cm and a length of about 2-2.5 m.

- Step 2. One end of such a pipe must be inserted into a film greenhouse or greenhouse, and a fire must be built under the other.

- Step 3. The fire now needs to be constantly maintained. The air will quickly heat up in the pipe, pass into the greenhouse and give off heat to the plants being grown.

This method of heating is really easy, but somewhat inconvenient due to the fact that the fire must be maintained constantly.

Option #3 – heating with gas

The main advantage of gas is that it is more stable in terms of supply, but the final cost of products from the greenhouse can surprise. Therefore, if heating a greenhouse with gas in winter lasts only a few weeks, then it is not necessary to pull it from a residential building and purchase expensive pipes for this. It will be enough to take a couple of cylinders for this purpose - they will last for a long time.

It is only important to remember that excess carbon dioxide can negatively affect the condition of plants, and therefore such a greenhouse must be well ventilated. And to remove combustion waste, it is necessary to use an exhaust device to ensure a constant flow of oxygen into the greenhouse. And so that the lack of oxygen does not lead to the cessation of the combustion process and the release of gas into the air, it is advisable to use heating devices with an automatic protective device - the sensors will immediately operate as soon as the gas supply to the burner stops.

Option #4 – stove heating

Unlike electric heating, classic stove heating is not so burdensome in terms of financially. So, you can build a simple greenhouse stove with a hog or a horizontal chimney with your own hands and without much expense. Its design principle is quite simple:

- Step 1. A brick furnace firebox is laid out in the vestibule of the greenhouse.

- Step 2. A chimney is laid along the entire length of the greenhouse, either under the beds or under the shelving.

- Step 3. This chimney is removed from the greenhouse on the other side so that carbon monoxide escapes and all the heat remains inside the building. As a result, the distance between the end wall of the greenhouse and the firebox itself should be at least 25 cm, but from the bed or rack with plants to the top of the hog - from 15 cm.

Or according to this scheme:

- Step 1. You need to take a large barrel, with a capacity of about 3 cubic meters, and paint it inside in 2 layers so that it does not rust.

- Step 2. Holes are made inside the barrel for the chimney, stove, expansion barrel on top and drain valve on the bottom.

- Step 3. The stove is cooked and inserted into the barrel.

- Step 4. A chimney is removed from the barrel, and a pipe 5 meters high is placed on the street.

- Step 5. A homemade 20-liter expansion tank is installed on top of the barrel, which is pre-cooked from simple sheet iron.

- Step 6. Heating is made from a 40x20x1.5 profile pipe, and the pipes are laid out on the ground at a distance of 1.2 m. It is necessary to lay them out this way so that the soil near the roots of the plants warms up well.

- Step 7. To circulate water in such a homemade heating system, purchase a special but inexpensive pump.

Such a stove can be heated with any kind of wood, and the drain valve at the bottom of the barrel can be used not only for draining water, but also for drip irrigation when the water itself has cooled. To control the temperature in such a greenhouse, you can install an electronic temperature sensor inside it, and the digital display itself can be installed right in the house.

Option #5 – water heating

Water heating for a greenhouse is one of the most profitable in financial terms. You can make an electric water heater with your own hands.

Method #1 – thermos from an old fire extinguisher

So, you will need the body of an old, no longer needed fire extinguisher, the top of which will be cut off. Work order:

- Step 1. At the bottom of the case you need to install a thermal electric heater with a power of 1 kW, which can be taken from an electric samovar.

- Step 2. To allow water to be poured into the electric heater, a removable lid is placed on top.

- Step 3. You need to attach two water pipes to the housing, which are connected to the radiator. The pipes must be secured with rubber seals and nuts.

In order for the heater to be automated, it is better to use such a circuit - with an alternating current relay, such as MKU-48 with a voltage of 220 V. As soon as the temperature sensor operates, it closes the contacts K1. The heater will begin to heat the water, and it will raise the temperature in the greenhouse. As soon as the water reaches the set level, the temperature sensor will immediately work and the power circuit of relay K1 will be broken, and the water electric heater itself will turn off. If the MKU-48 relay cannot be found, you can use the second circuit, where the relay has contacts that do not pass a current of less than 5A.

Method #2 – heating element + old pipes

In this case, a small number of old pipes, a heating element and an electric welding machine will be used. Everything will be produced quickly and reliably.

So, in a convenient corner of the greenhouse you need to install a boiler with a volume of about 50 liters and an electric heater of 2 kilowatts. When heated, the water will rise into the expansion tank along the riser and will be supplied to the heating system located around the entire perimeter. The system itself should have a slight downward slope of the pipes.

Step 1. The boiler will need to be made from a piece of large diameter pipe, to which the bottom with a flange will be welded.

Step 1. The boiler will need to be made from a piece of large diameter pipe, to which the bottom with a flange will be welded.

Step 2. The heating elements must be connected with an electrical cord to a plug and securely insulated.

Step 3. All joints between the flange and the body must be well sealed with a rubber gasket.

Step 4. An expansion tank with a volume of up to 30 liters is made from pipe scraps. Couplings are welded at the bottom and at both ends to connect to the boiler riser and to the system.

Step 5. A cap is cut out in the tank itself for adding water, because its level will need to be constantly monitored.

Step 6. A pipeline is made from metal pipes, the ends of which must be threaded in advance for easy connection.

Step 7. Now the boiler body must be grounded with a flexible three-core copper wire, which is designed for a voltage of 500 V and without insulation. Both wires need to be attached to the phases of the heating element, and the third wire to the boiler body. By the way, during cold weather it will be possible to use special screens made of foil or other heat-reflecting material.

The main thing is that during any installation of a heating system for a greenhouse or greenhouse, follow all safety rules and strictly follow the instructions.

Method #3 - installing a solid fuel boiler

The boiler itself can be located either in the greenhouse or in a separate room. The advantage of the second option is that you can put firewood or fuel into the boiler without going into the greenhouse, and now it will not take up valuable space, like the fuel itself. The downside is that the boiler also produces a little heat energy, which would not be unnecessary for the greenhouse.

You need to add fuel to the heat generator 2 times a day - that’s all. And such a boiler is absolutely fireproof, and therefore can be safely left overnight without any control. In addition, fuel consumption is quite low.

If you decide to build a stationary greenhouse for year-round cultivation vegetables, then in any case it is necessary to resolve the issue of heating it in winter and during the transition period. There are many in various ways, how to organize heating of a greenhouse, and most of them can be done with your own hands. In the article we will look at these methods, and also give recommendations on calculating the power of the heating system and choosing a source of thermal energy.

Types of greenhouse heating

There really are a lot of options for heating such structures, no less than for private houses. This is easy to verify if you study heating projects for farm greenhouses of different sizes posted on various Internet resources.

Depending on the method of transferring heat inside the building, heating systems are of the following types:

- air;

- water;

- combined with direct heating of the soil.

For reference. Large farm greenhouses often use infrared heating with gas or electric heaters.

In the first case, one or more heat sources directly heat the air in the building, which is easier and cheaper to implement. It is more difficult to make water heating in a greenhouse with your own hands, but the effect will be greater, since it makes it possible to heat the growing areas of vegetables, and not the entire volume of the building. The optimal solution is a combined one, when the planting soil and the air in the greenhouse structure are heated separately.

When choosing a heating method, the question inevitably arises: what is the best way to heat a building, what energy carrier to use for this purpose? There are several options here:

- natural or liquefied gas;

- electricity;

- various types of solid fuel (wood, coal).

The choice of energy carrier depends on individual conditions in each specific case, so you will have to make it yourself. We will look at how you can heat a winter greenhouse with one fuel or another and what system designs are used for this. True, there are also alternative heat sources, for example, solar collectors or geothermal systems. But the former are ineffective in winter, and the latter are incredibly expensive, so there is no point in taking them into account.

Heating with natural gas

This energy carrier is very convenient to use, although you won’t be able to install and connect it yourself; this should be done by a specialized company. If you do not take into account this point, and even the cost of gas for the population different countries CIS, then this is one of best options for greenhouses. Using gas heating, you can organize air, water and infrared heating methods winter greenhouse.

A common practice is to install infrared gas heaters on the roof of the room. If the structure has a small width, then the units will be placed along the axis of the building in one row. It is important that all beds fall within the operating range of the device in width (it is indicated in the operating instructions). When this cannot be achieved, gas appliances are placed in 2 or 3 rows.

The advantage of gas infrared heating in winter is the direct heating of the soil, and only then the air in the greenhouse. The disadvantage is the need for ventilation to remove combustion products.

Another option is a gas boiler plus a water heating system for the greenhouse. You need to understand that in greenhouse structures the main task is to provide heat to the plants, and not to warm people. To do this, wiring is made of smooth pipes with a diameter of no more than 40 mm over the entire area. Moreover, they are laid along each bed at a height of 20-30 cm from ground level. The following types of wiring are allowed:

- the supply line is along one wall, the return line is near the other. They are connected to each other by transverse pipes running between the beds;

- supply and return are laid along one wall. Each heating pipe runs along one bed and returns past another;

- the pipe is laid in a snake pattern over the entire area of the greenhouse, forming a single heating circuit.

Advice. Shut-off valves must be installed on each branch so that the circuit can be turned off when the plants have already been harvested.

Additionally, in order to warm the air inside the structure, it is recommended to install several heating devices near the walls. Usually these are registers made of smooth pipes, made by hand. As you already understand, installing such a system will require a lot of work, but you will only spend money on a gas boiler and its connection. You can go another way: arrange air heating of the greenhouse by installing several gas convectors.

Electric heating

If we are talking about the device of water electric heating, then it is carried out according to the same scheme as gas heating. Only now we have a different heat source - a heating element, electrode or induction boiler. No permits are required for its installation, so you can do the work yourself.

It is even easier to make infrared heating using hanging devices; they do not require ventilation to operate. They are placed in the same way as gas ones, by attaching them to the roofing part.

There is an option for combined heating of a winter greenhouse, when an electric heating cable or heating film is laid in the ground. In this case, the space inside the structure is heated with air heaters (fan heaters) or homemade oil radiators. Here the choice is entirely yours, as long as the supplied electrical power is sufficient.

It is noteworthy that electric heating of a winter greenhouse can be economical, despite high tariffs. After all, the coldest time is at night, when the cost of electricity is minimal, you just need to use a multi-tariff meter. In addition, such systems are easily regulated and automated.

Use of solid fuel

Heating greenhouses with wood is the most common and cheapest method, although it is troublesome. Most often, it is implemented using homemade stoves - brick or metal, for example, the Buleryan type.

One or more stoves are installed in the center of the structure, and its chimney is first laid horizontally and only then turns and goes out onto the street. The goal is to extract as much heat from the flue gases as possible, so that the horizontal section can reach a length of 10 m.

Advice. The horizontal pipe should be laid with a slope towards the stove in order to facilitate the passage of combustion products and improve natural draft.

When it is planned to install a water heating system, a solid fuel boiler is installed in the greenhouse or outside it. The first option is more preferable, since all the heat will remain inside the building, while the second is used when supplying heat to several greenhouse structures from one solid fuel boiler. It is important to take into account 2 points: insulate the highways passing along the street, and do not install shut-off valves on pipe sections outside the greenhouse.

How to choose a boiler for a greenhouse

Regardless of whether you decide to heat the building with wood or electricity, you must first find out the amount of heat required for it. Here you cannot do without a calculation, and in order to carry it out, you need to know the exact area of the floor and the translucent part of the greenhouse. In addition, you need to find data on the lowest daily temperature for your area, as well as the average wind speed during these days. This information is specified in the standard called “Building Climatology and Geophysics”.

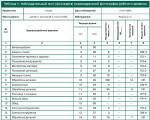

On the nomogram shown above, we find a graph corresponding to the lowest temperature. Then, from the abscissa axis (wind speed), we draw a line until it meets this graph and determine the specific heat loss along the ordinate axis in relation to the enclosure coefficient. It is easier to show the calculation using an example for a greenhouse with a floor area of 700 m2 and glazing area of 980 m2. Then, with a wind of 4.7 m/s and a temperature of -30 °C, according to the graph, the value of Q/k is equal to 388 W/m2.

Now we need to find the fencing coefficient k, it is equal to the ratio of the area of translucent structures to the floor area. In our example, k = 980 / 700 = 1.4, then Q = 388k = 388 x 1.4 = 543 W/m2. All that remains is to find out the total heat loss by multiplying the specific heat loss (543 W/m2) by the area of the polycarbonate greenhouse (700 m2): 700 x 543 = 380,000 W or 380 kW.

To select a boiler for a greenhouse, you need to multiply the heat loss value by the safety factor. Whatever heat source you take - solid fuel or gas, it cannot work at maximum all the time. For those greenhouses built from polycarbonate or using glass, the safety factor will be 1.3, and those covered with ordinary film - at least 1.5.

Advice. It is always better to select a solid fuel boiler that burns for a long time with one and a half power reserves and a large firebox. This will save you from frequently loading firewood or coal in the middle of the night.

Conclusion

Organizing the heating of a winter greenhouse is a simpler undertaking than heating a residential building. Here almost all the work can be done independently if you have the appropriate skills. The main thing is to choose a suitable heat source and energy carrier. Finally, a traditional tip on energy saving: in greenhouses it is very important to insulate the floors under the beds, which will provide significant savings. Foam plastic with a thickness of at least 100 mm is well suited for this purpose.

What heating method is the most effective, and how to arrange it? What is good about water heating in a greenhouse, and can it be combined with air heating in greenhouses? We will try to answer these questions in this article.

Heating of greenhouses can be different:

- stove;

- gas;

- electric;

- steam;

- watery.

In order to efficiently heat a greenhouse with your own hands, to provide plants with comfort for their growth, especially when heating the greenhouse in winter, you need to choose a type of heating system that will fully heat both the soil and the air.

Selecting a heating method

The correct choice of greenhouse heating method will determine your future harvest. When making this choice, you need to consider:

- greenhouse dimensions;

- type of home heating system;

- own financial capabilities.

It is important to match the heating system with the type of greenhouse. Thus, it is well known that heating greenhouses made of film materials requires more heat than heating, since this material itself is a good heat insulator.

It is necessary to take into account the characteristics of a particular system. For example, some of them, although highly effective, being extremely expensive, are completely unsuitable for standard small greenhouses. Other systems require installation and configuration by a professional. This especially applies to systems that use advanced technologies, such as heat pumps, infrared heating, etc.

When setting up a greenhouse heating system on your own, you first need to “feel” how the process of such heating will proceed, and take into account all its pros and cons when choosing a heating system.

Water heating of a greenhouse - what are its advantages?

The use of water heating in a greenhouse ensures that both air and soil are heated simultaneously. An optimal microclimate is established and maintained in the greenhouse, and the air does not dry out, as is observed with other heating methods. At the same time, it is very important to provide the greenhouse with the correct ventilation system, so we also recommend that you read the article material that will help you.

From an economic point of view, heating with water is more profitable, since heating can run on different fuels:

- on wood;

- on coal;

- on peat;

- on household waste;

- on industrial waste and other types of fuel.

Simply put, you can use anything that can burn for water heating in a self-made greenhouse.

Greenhouse heating design with water

The heating system consists of:

- heating boiler or furnace;

- pipes;

- radiators;

- expansion tank;

- chimney;

- circulation pump.

The choice of heating boiler depends on the specific situation. In gasified areas, the most popular are economical ones. gas boilers. However, options for constructing systems with electric heating boilers and boilers for solid fuel are also possible. The simplest option is a stove made of brick or metal, burning coal or wood, which you can build with your own hands.

The water heated in the boiler is fed into the pipes by a circulation pump. It is best to form two heating circuits from them.

- The first circuit is subsoil, consisting of plastic pipes with water at a temperature of about 30 ° C, laid in the root zone of plants.

- The second circuit is heating the under-dome volume of the greenhouse using radiators.

Water in the system usually circulates forcibly under pressure created by a circulation pump, less often - naturally.

Connecting your own thermostats to the system makes it possible to maintain a certain temperature automatically.

Radiators, as well as the pipes supplying water to them, can be according to the owner’s preferences:

- cast iron;

- bimetallic;

- aluminum.

Radiator-free systems are generally known, in which the under-dome space of greenhouses is heated from round steel pipes with a large diameter.

An expansion tank, either open or closed, is absolutely necessary, and can either be purchased ready-made or welded from sheet metal with your own hands.

The chosen method of obtaining hot water is from a boiler or from a metal or brick stove, and the type of chimney is also selected. It could be:

- classic brick chimney;

- asbestos-cement;

- metal pipe.

If financial capabilities allow, then you can use modern sandwich pipes.

Is a circulation pump necessary?

The presence of a circulation pump in the water heating method of greenhouses is not unambiguous. Budget greenhouses often have water heating with natural circulation of water due to the pressure difference in the system. So water heating can work both with and without a pump, everything is determined again financial capabilities owner of the greenhouse.

Sometimes, when a greenhouse is attached directly to the residential building itself, its water heating receives hot water from the in-house heating system. If the greenhouse is remote from the house, then insulating the pipes running along the street requires significant investments of effort and money, but this will not guarantee complete protection of the pipes from exposure low temperatures winter season. We recommend that you learn about .

DIY water heating of a greenhouse (video)

Do-it-yourself heating system installation

The stove or heating boiler is usually located in the vestibule of the greenhouse, or less often inside the greenhouse itself. In the first option, fuel (wood, coal) does not interfere with movement in the greenhouse and work with hands and tools in it. But in the second option, the stove or boiler itself also radiates additional heat into the air. Therefore, choosing their location is the task of the greenhouse owner. For lovers greenhouse farms, will be interesting and .

- A foundation should be built under the boiler or furnace. For a brick stove it should be made of concrete, for a metal stove or a small boiler - from steel or asbestos-cement sheet. It is only important that the heat source is stable and does not create a fire hazard.

- A chimney (flue pipe) extends from the stove (boiler). The joints of its parts (elements) and the junction with the stove (boiler) are hermetically sealed with your own hands or with the help of assistants to prevent smoke from entering the greenhouse. If the joints are sealed with a solution, then only with clay, since cement will crack due to high temperatures.

- The winter greenhouse should be equipped with ventilation, regardless of the heating method.

- Only metal pipes of the same diameter should be connected to the boiler outlet and inlet pipes. At a distance of a meter or one and a half from the boiler, you can already install plastic pipes if the main pipeline of the system is made from them.

- Before installing a greenhouse heating system with water, install an expansion tank at the highest point of the building near the stove or boiler. For safety reasons, an automatic air shut-off valve and a pressure gauge are installed in front of it.

- Now you can install the heating system circuits themselves: primary and secondary with radiators. Considering that the running water circulates naturally due to the pressure difference created by hot and cold water, the outlet pipes from the furnace (boiler) should be located in the middle between the mounted radiators.

- If radiators are equipped with shut-off valves, then it is necessary to install jumpers between the incoming and outgoing pipes from the radiators so that the disconnected radiator does not stop the operation of the entire system.

He will tell you about a budget heating option .

Basic rules for installing a subsoil heating circuit in a greenhouse with your own hands

- For subsurface heating it is better to use pipes high quality made of cross-linked polyethylene, placed directly in the ground, and if the soil heating circuit is equipped with an automatic control unit, it is possible to provide temperature conditions, corresponding to different stages of plant development, which will significantly increase productivity.

- The structure of the soil heating circuit in a greenhouse resembles a “warm floor” system. The pitch of laying plastic pipes is at least 0.3 m; this must be taken into account if you install such a system with your own hands.

- To prevent heat from escaping into the ground, a layer of thermal insulation made of a material that does not absorb moisture (for example, polystyrene foam) is needed; for additional waterproofing, a polyethylene film is laid over the thermal insulation layer.

- Polyethylene pipes for heating the soil are laid in a cushion of sand (washed and compacted) about 10 - 15 cm thick, which will promote uniform heating of the soil and prevent overdrying of the soil.

- The thickness of the layer of fertile soil to be filled must be at least 30 - 35 cm.