Noise training on general issues of certification of workplaces on working conditions

The concept of noise

Noise- these are random fluctuations of various physical nature, characterized by the complexity of the temporal and spectral structure. From a physiological point of view, noise is any adverse perceived sound.

Sound- these are elastic waves propagating longitudinally in the medium and creating mechanical vibrations in it; in a narrow sense - the subjective perception of these vibrations by special human senses.

The impact of the factor on the human body

Prolonged exposure to noise can cause hearing loss and, in some cases, deafness. Noise exposure in the workplace adversely affects workers and leads to:

- slowing down the speed of mental reactions, etc.

decreased attention;

increase in energy consumption with the same physical load;

The concept of sound is usually associated with the auditory sensations of a person with normal hearing. Auditory sensations are caused by vibrations of an elastic medium, which are mechanical vibrations propagating in a gaseous, liquid or solid medium and affecting the human hearing organs. In this case, vibrations of the environment are perceived as sound only in a certain frequency range (20 Hz - 20 kHz) and at sound pressures exceeding the human hearing threshold.

As a result, labor productivity and the quality of work performed are reduced.

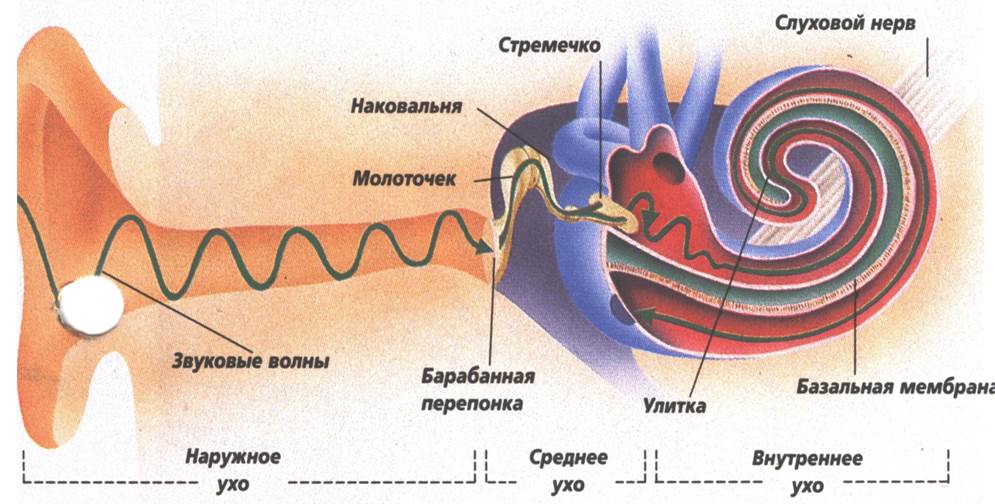

Figure 1 shows the structure of the organ of hearing.

Figure 1 - The structure of the organ of hearing

The primary analysis of sound takes place in the cochlea. Each simple sound has its own area on the basilar membrane. Low sounds cause vibrations in sections of the basilar membrane at the top of the cochlea, and high sounds at its base.

The wave moves from the stirrup to the top of the cochlea. When the amplitude reaches its maximum, the wave quickly decays. In this area, eddy currents of the perilymph arise, and the maximum deflection of the basilar membrane occurs. Low frequency sounds will travel through the entire cochlea and cause maximum deflection at the tip. High frequency sounds will vibrate the basilar membrane only at the base of the cochlea. The nervous excitation that has arisen in the auditory receptor is transmitted along the auditory nerve to the auditory zone of the cerebral cortex, where a sound image is formed. Figure 2 shows the mechanism of the formation of audible sounds.

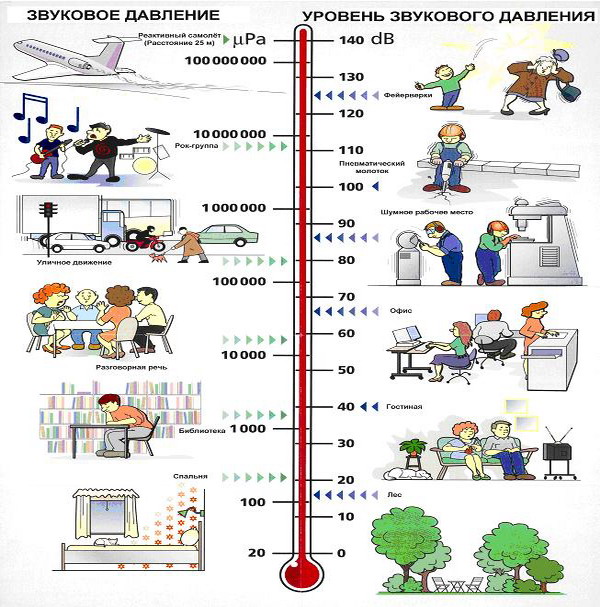

Figure 2 - The mechanism of the formation of audible sounds

Areas of perception of sound intensity levels

- III area - covers levels from 80 - 90 dB to the threshold of unpleasant sensation - 120 - 130 dB. In this area, the functions of the auditory analyzer have significant differences depending on the frequency, intensity and time of exposure to sound.

I region - includes a range of levels from the threshold of hearing to 40 dB and covers a limited number of signals, as a result of which a person does not have daily training to perceive such sounds; while the ability to differentiate sounds is limited.

II area - includes levels from 40 to 80 - 90 dB and covers the bulk of useful signals, speech intensity levels from a whisper to the loudest radio transmission, musical sounds, etc. fit into this area. Here, the ability to finely differentiate and analyze the quality of sound (both in frequency and intensity) is noted. A person is most adapted to the perception of sounds in this area.

Factor classification

The classification of the "Noise" factor is given in Table 1.

Table 1

| Classification method | Type of noise | Noise characteristic |

|---|---|---|

| By the nature of the noise spectrum | Tonal | Noise spectrum has distinct discrete tones |

| Broadband | Continuous spectrum more than one octave wide | |

| By temporal characteristics | Permanent | Sound level changes by no more than 5 dB(A) over an 8-hour working day |

| Non-permanent: | ||

| fluctuating in time | The sound level changes by more than 5 dB(A) over an 8 hour working day. Sound level changes continuously over time | |

| intermittent | The sound level changes in steps by no more than 5 dB(A), the duration of the interval is 1 s or more | |

| Pulse | Consist of one or more beeps, the duration of the interval is less than 1 s |

Normalized indicators of factors

Normalized indicators for constant and intermittent noise are given in Table 2.

table 2

Regulations

The maximum permissible noise levels at workplaces are set taking into account the severity and intensity of labor activity. To determine the maximum noise level corresponding to a particular workplace, it is necessary to quantify the severity and intensity of the work performed by the employee. The maximum permissible sound levels and equivalent sound levels at workplaces for work activities of different categories of severity and intensity in dBA are presented in Table 3.

Table 3. Maximum permissible sound levels and equivalent sound levels at workplaces for work activities of different categories of severity and intensity in dBA

Maximum permissible sound pressure levels, sound levels and equivalent sound levels for the main most typical types of work and jobs are presented in Table 4.

| Type of work activity, workplace | Sound levels and equivalent sound levels in dBA |

| Creative activities, leadership work with increased requirements, scientific activities, design and engineering, programming, teaching and learning, medical activities. Workplaces in the premises of the directorate, design bureaus, calculators, computer programmers, in laboratories for theoretical work and data processing, admission of patients in health centers | 50 |

| Highly qualified work requiring concentration, administrative and managerial activities, measurement and analytical work in the laboratory; workplaces in the premises of the shop management apparatus, in the working rooms of office premises, in laboratories | 60 |

| Work performed with frequently received instructions and acoustic signals; work requiring constant auditory control; operator work according to the exact schedule with instructions; dispatch work. Workplaces in the premises of the dispatching service, offices and rooms for monitoring and remote control with voice communication by telephone; typing bureaus, precision assembly areas, telephone and telegraph stations, craftsmen's rooms, information processing rooms on computers | 65 |

| Work that requires concentration; work with increased requirements for the processes of monitoring and remote control of production cycles. Workplaces at consoles in observation and remote control booths without voice communication by telephone, in rooms for placing noisy computer units | 75 |

| Performance of all types of work (with the exception of those listed in paragraphs 1–4 and similar ones) at permanent workplaces in production premises and on the territory of enterprises | 80 |

| Workplaces in the cabs of drivers of diesel locomotives, electric locomotives, metro trains, diesel trains and railcars | 80 |

| Workplaces in the cabs of drivers of high-speed and suburban electric trains | 75 |

| Premises for personnel of long-distance train cars, service rooms, refrigerated sections, power station cars, luggage and post office rest rooms | 60 |

| Office space in baggage and mail cars, dining cars | 70 |

| Workplaces for drivers and service personnel of trucks | 70 |

| Workplaces for drivers and attendants (passengers) of cars and buses | 60 |

| Workplaces for drivers and maintenance personnel of tractors, self-propelled chassis, trailed and mounted agricultural machines, road construction and other similar machines | 80 |

Table 4. Maximum permissible sound pressure levels, sound levels and equivalent sound levels for the main most typical types of work and workplaces

Classes of working conditions depending on noise levels are presented in table 5

Table 5. Classes of working conditions depending on noise levels in the workplace

Measurement technique

When measurements are made in some reference time intervals, they are chosen so that they cover all typical and repetitive day-to-day noise situations [it is important to identify all significant changes in noise in the workplace, for example by 5 dB (dBA) or more]. In this case, the measurement results obtained in different shifts will not be contradictory.

Duration of measurements within each reference time interval

- for intermittent noise, the causes of fluctuations of which cannot be clearly related to the nature of the work performed - 30 minutes (three measurement cycles of 10 minutes each) or less, if the measurement results for a shorter duration do not differ by more than 0.5 dB (dBA);

for constant noise at least 15 s;

for non-constant, including intermittent, noise, it must be equal to the duration of at least one repetitive operating cycle or a multiple of several operating cycles. The duration of measurements can also be equal to the duration of some characteristic type of work or part of it. The duration of measurements is considered sufficient if, with its further increase, the equivalent sound level does not change by more than 0.5 dBA;

for impulse noise - not less than the transit time of 10 impulses (recommended 15 - 30 s)

Noise measurements to control the compliance of actual noise levels at workplaces with permissible levels according to current standards should be carried out when at least 2/3 of the units of installed equipment commonly used in a given room are operating in the most frequently implemented (characteristic) mode of its operation or in another way, when a typical noise impact from noise sources that are not at the workplace (in the working area). If it is known that the equipment located far from the workplace creates background noise on it 15 - 20 dB lower than the noise during operation of the equipment installed at this workplace, then it should not be turned on.

Measurements should not be carried out when employees are talking, as well as when various sound signals are given (warning, information, telephone calls, etc.) and during loudspeaker operation.

Measurements can be carried out in the presence or absence (the latter is preferable) of an operator (working) at the workplace or in the working area. Measurements are carried out at fixed points or with a microphone attached to the operator and moving with him, which provides a higher accuracy in determining the noise level and is preferable.

Fixed point measurements are made if the position of the operator's head is known accurately. In the absence of an operator, the microphone is installed at a given measurement point located at the level of his head. If the position of the operator's head is not exactly known and the measurements are carried out in the absence of the operator, then the microphone is installed for a seated workplace at a height of (0.91 ± 0.05) m above the center of the seat surface with its average adjustment position according to the operator's height, and for a standing worker places - at a height of (1.550 ± 0.075) m above the support on the vertical passing through the center of the head of an upright person.

If the presence of the operator is necessary, the microphone should be placed approximately 0.1 m from the ear receiving the higher (equivalent) sound level and oriented in the direction of the operator's gaze, if possible, or in accordance with the manufacturer's instructions. If the microphone is fixed on the operator, then it is mounted on the helmet or shoulder with the help of a frame, as well as on the collar at a distance of 0.1 - 0.3 m from the ear, but in such a way as not to interfere with the work of the operator and not create danger to him.

The microphone must be at least 0.5 m away from the operator taking the measurements.

In the vicinity of a noise source, even slight changes in the position of the microphone can significantly affect the measurement results. If the tones are clearly distinguishable at the measurement point, then standing waves may occur. It is recommended to move the microphone several times in the zone of 0.1 - 0.5 m and take the average value as the measurement result.

When the microphone is placed close to the operator, there may be a noticeable difference in measurements with and without the presence of the operator (usually, the results of measurements with the presence of the operator are higher). This is especially evident when measuring high-frequency tonal noise or the noise of small sources at a close distance from them. To prevent gross errors, it is recommended to compare the measurement results with and without the presence of an operator and, in case of a significant difference, calculate the average value.

Octave levels of sound pressure, sound levels are measured by sound level meters of the 1st or 2nd accuracy class.

The instrumentation is calibrated before and after the noise measurement is carried out in accordance with the instructions for use of the instruments.

Figure 3 shows sound pressure level measuring instruments.

Figure 3 - Instruments for measuring the sound pressure level

Actual sound pressure levels

Examples of actual sound pressure levels are shown in Figure 4.

Figure 4 - Actual sound pressure levels

Measures to eliminate the harmful effects of noise

Noise protection measures for workplaces of industrial enterprises are primarily provided by the following construction and acoustic methods.

Rational from an acoustic point of view, the solution of the general plan of the object, rational architectural and planning solution of buildings

The main principle of protection is the grouping of rooms with increased noise levels and their separate location from other parts of the building. As for the equipment of these rooms, it is considered most favorable to install it in the center of the room. In this case, there will be only one reflective surface nearby - the floor. If the equipment is installed against a wall, it will also reflect sound waves and the noise will be amplified. This principle also applies to protection against structure-borne noise, with the only difference that the equipment must not touch the walls of the room.

The use of building envelopes with the required sound insulation

Enclosing structures of buildings are walls, ceilings, partitions, etc. They are divided into external and internal. External ones serve to protect against various climatic factors, and internal enclosing structures - to separate and redevelop the internal space of the building.

Fencing elements are recommended to be designed from materials with a dense structure that does not have through pores. Fences made of materials with through porosity must have outer layers of dense material, concrete or mortar.

It is recommended to design internal walls and partitions made of bricks, ceramic and cinder blocks with full-thickness filling of joints (without hollowing) and plastered on both sides with a non-shrinking mortar.

The enclosing structures must be designed in such a way that during construction and operation there are no and no even minimal through cracks and cracks in their joints. Cracks and cracks arising during the construction process after their clearing should be eliminated by constructive measures and sealed with non-drying sealants and other materials to the full depth.

Sound insulation of building structures is carried out by covering them with sound-absorbing materials. The effectiveness of sound insulation depends on the type of material used and on its thickness. The most efficient are fibrous materials, which, due to their structure, transmit only a small percentage of noise. The thickness and material of structures is determined on the basis of acoustic calculations.

The use of sound-absorbing structures

The presence of reflections of sound waves from the surfaces of an enclosed space (room) and objects located in it usually increases the sound intensity compared to the levels created by the same sound source radiating into a free (open) space. To eliminate the reflected part of the sound field, various sound-absorbing materials and structures based on them are used.

Sound-absorbing structures (suspended ceilings, wall cladding, rocker and piece absorbers) should be used to reduce noise levels at workplaces and in areas of permanent residence of people in industrial and public buildings.

Sound-absorbing structures should be placed on the ceiling and on the upper parts of the walls. It is advisable to place sound-absorbing structures in separate sections or strips. At frequencies below 250 Hz, the effectiveness of the sound-absorbing cladding increases when it is placed in the corners of the room.

The area of sound-absorbing linings and the number of piece absorbers are determined by calculation.

Piece absorbers should be used if the cladding is not enough to obtain the required noise reduction, and also instead of a sound-absorbing suspended ceiling, when its installation is impossible or ineffective (large production room height, overhead cranes, light and aeration lamps). As mandatory measures to reduce noise and ensure optimal acoustic parameters of the premises, sound-absorbing structures should be used: in noisy workshops of manufacturing enterprises; in computer rooms of computer centers; in soundproof booths, boxes and shelters.

The acoustic properties of materials essentially depend on their structural parameters, which determine the scope of these materials. So, if noise reduction is required in the low-frequency region, then it is advisable to use linings made of ultra- or super-thin fibrous materials with a density of 15–20 kg/m3. To reduce broadband noise in the medium and high frequency range, materials with larger fibers with a density of 20–30 kg/m3 or more should be chosen.

It should be noted that in the area of direct sound, sound-absorbing structures practically do not reduce noise levels.

Application of soundproof observation and remote control booths

Soundproof booths should be used in industrial workshops and in areas where permissible levels are exceeded to protect workers and maintenance personnel from noise. In soundproof cabins, control panels and controls for “noisy” technological processes and equipment, workplaces for foremen and shop supervisors should be located.

Depending on the required soundproofing, cabins can be designed from conventional building materials (brick, reinforced concrete, etc.) or have a prefabricated structure assembled from prefabricated structures made of steel, aluminum, plastic, plywood and other sheet materials on a prefabricated or welded frame .

Soundproof booths should be installed on rubber vibration isolators to prevent the transmission of vibrations to the enclosing structures and the booth frame. The internal volume of the cabin must be at least 15 m3 per person. Cabin height (inside) - not less than 2.5 m. The cab must be equipped with a ventilation or air conditioning system with the necessary silencers. The interior surfaces of the cabin must be 50 - 70% lined with sound-absorbing materials.

Cabin doors must have sealing gaskets in the porch and locking devices that ensure compression of the gaskets. Cabins of the 1st and 2nd classes must have double doors with a vestibule.

Use of soundproof enclosures on noisy units

The use of soundproof casings is one of the most effective solutions to the problem of isolating units with a high level of noise. It is advisable to use a soundproof casing in cases where the noise generated by the unit (machine) at the design point exceeds the permissible value by 5 dB or more in at least one octave band, and the noise of all other process equipment in the same octave band (at the same design point ) is 2 dB or more below the permissible value.

Soundproof casings are usually made of fibrous materials, and thin perforated metal panels serve as a frame. If the value of sound insulation of airborne noise does not exceed 10 dB at medium and high frequencies, then the casing can be made of elastic materials (vinyl, rubber, etc.), if it exceeds, the casing should be made of sheet structural materials. The casing elements must be attached to the frame.

The metal casing should be covered with a vibration-damping material (sheet or in the form of mastic), while the thickness of the coating should be 2-3 times greater than the wall thickness. A layer of sound-absorbing material 40-50 mm thick should be placed on the inside of the casing. To protect it from mechanical impacts, dust and other contaminants, a metal mesh with fiberglass or a thin film 20-30 microns thick should be used.

The casing must not be in direct contact with the unit and piping. Technological and ventilation openings must be equipped with silencers and seals. The installation of soundproof casings is one of the main measures to reduce the noise of ventilation equipment in buildings and premises. They are installed on supply, some exhaust units and air conditioners. Soundproof casings are two metal sheets with sound-absorbing material between them. The acoustic efficiency of such enclosures can be up to 10-15 dB at low frequencies and up to 30-40 dB at high frequencies.

Application of acoustic screens

The acoustic screen is a kind of barrier between the workplace and the noise source, which has a high level of sound insulation. Screens should be used to reduce sound pressure levels at workplaces in the area of direct sound and in the intermediate area. Screens should be installed as close as possible to the noise source.

Screens should be made of solid sheet materials or separate panels with obligatory lining with sound-absorbing materials on the surface facing the noise source.

Structurally, screens can be flat and U-shaped (in this case, their efficiency increases). If the screen surrounds the noise source, then it turns into a barrier and its efficiency approaches the efficiency of an infinite screen with height h. It is advisable to use baffles for a noise source (sources) whose sound power levels are 15 dB or more higher than those of other noise sources.

Screen elements can be located vertically and at a certain inclination to the horizontal (vertical) plane. The angle of inclination depends on the relative position of the noise source and the workplace.

The main parameters of the screen (height, shape, thickness of the sound-absorbing cladding), which provide a given acoustic efficiency at a fixed distance to the noise source, are determined by calculation. The linear dimensions of the screens must be at least three times the linear dimensions of the noise source.

Reduction of fan noise and the use of noise suppressors in ventilation, air conditioning and aerogasdynamic installations

To reduce fan noise, you should: choose a unit with the lowest specific sound power levels; ensure the operation of the fan in the maximum efficiency mode; reduce the resistance of the network and do not use a fan that creates excessive pressure; provide a smooth air supply to the fan inlet.

To reduce noise from the fan along the path of its propagation through the air ducts, it is necessary to: provide central (directly at the fan) and end (in the air duct in front of the air distribution devices) silencers; limit the speed of air movement in the networks to a value that ensures the noise levels generated by the control and air distribution devices within the permissible values in the serviced premises.

As silencers for ventilation systems, tubular, plate, channel, cylindrical, screen and chamber, as well as air ducts lined with sound-absorbing materials and their turns can be used.

The design of the silencer should be selected depending on the size of the duct, the required reduction in noise levels, the allowable air velocity based on the calculation according to the relevant code of practice.

Vibration isolation of technological equipment

Airborne noise, especially vibrations, propagating with low attenuation along the supporting and enclosing structures of buildings, as well as along pipelines and walls of channels and shafts in buildings, are emitted by them in the form of structural (shock) noise in rooms that are far from noise and vibration sources. Protection against structural noise is carried out by methods of acoustic vibration isolation of engineering equipment and its communications. These methods include the installation of flexible connectors and vibration isolators, equipping the premises with floors on an elastic base (floating floors).

In the first case, to reduce the structural noise of ventilation equipment, flexible linen canvas inserts are installed on the discharge and suction sides of the fans. Inserts are manufactured in accordance with standard drawings and have a rectangular and round cross section. For pumps and refrigeration machines, flexible inserts in the form of rubber sleeves are used.

Another way is to reduce noise through the use of vibration isolators. To achieve the goal in practice, vibration isolators of two types are often used: steel spring and rubber vibration isolators.

Rubber vibration isolators with a maximum allowable static deflection of 30% of their height are used above 1800 rpm. These vibration isolators effectively reduce vibration transmission at high frequencies. However, their use does not significantly reduce vibration transmission at low frequencies. In addition, rubber vibration isolators have low wear resistance. The most effective is the use of combined vibration isolators, consisting of spring vibration isolators, which are installed on rubber or cork gaskets 10–20 mm thick and are adjacent to the supporting surface.

The third way is the use of floors on an elastic base (floating floors). Their effectiveness may be lower than that of vibration isolators (in the calculated frequency band), but the damping ability of such floors is manifested in a wide frequency range.

In structures of this type, as well as in general when soundproofing, it is necessary to strictly monitor the absence of through holes and slots in insulating structures, the tight adjacency of elements to each other. In the case of “floating floors”, elastic pads should go up onto the walls along their perimeter, preventing hard mechanical contact of the floor (screed) with the walls.

It is necessary to note the organizational methods of noise protection (see below).

Selection of rational modes of equipment operation, limiting the time spent by personnel in the operating area of units (machines) with an increased noise level (protection by "time")

Protection by "time" provides for being in rooms with a high level of noise only for business purposes with a clear regulation of the time of the actions performed; work automation; reducing the time of adjustment work, etc.

The duration of additional regulated breaks is set taking into account the noise level, its spectrum and personal protective equipment. For those groups of workers where, according to safety regulations, the use of anti-noise devices (listening to signals, etc.) is not allowed, only the noise level and its spectrum are taken into account.

Rest during the period of regulated breaks should be carried out in specially equipped rooms. During the lunch break, workers exposed to elevated noise levels should also be in optimal acoustic conditions (with a sound level of no more than 50 dBA).

Use of personal hearing protection

Hearing protectors include hearing protectors, earmuffs and helmets. The effectiveness of PPE can be ensured by proper selection depending on the levels and spectrum of noise, as well as by monitoring the correct operation.