Where the gantry crane is de-energized. Dismantling of cranes. Dismantling of crane beams. Dismantling of gantry cranes. Dismantling of crane tracks. Technical side of the issue

Dismantling of cranes. Dismantling of crane beams. Dismantling of gantry cranes. Dismantling of crane tracks.

Not every client understands what a process like dismantling a crane in production involves. This is a very difficult and responsible task. We dismantle cranes of a wide variety of designs for the purpose of repair, restoration or disposal. Our specialists perform the work at a time convenient for clients. We are armed with the most modern equipment necessary to ensure high quality services provided. Considering the large mass and bulkiness of the crane, as well as its complex design, the procedures associated with its disassembly must be trusted exclusively to organizations specializing in this. The process itself is quite dangerous in terms of the possibility of injury, so professionals know and follow all safety precautions, which completely relieves the customer of any responsibility. Our specialists have extensive experience in performing such work. They are in the most short terms will be disassembled, transported and, if necessary, installed at a new location. We dismantle cranes of any lifting capacity, which are located both indoors and outdoors.

Dismantling of overhead cranes and crane beams

Operations to dismantle a crane located indoors require preliminary preparation. In the place where the crane will be lowered, it is necessary to remove machines and other mechanisms. In addition, access roads need to be prepared for the truck crane. After this, the danger zone should be fenced off and unauthorized persons should not have access to the work area. Next, prepare special equipment, which is used for securing and lowering structural elements tap.

Immediately before dismantling the crane, our specialists examine all its elements for possible detection of unreliable areas that may be subject to corrosion or be deformed. This makes it possible to take preventive measures to eliminate the possibility of accidental collapse of the structure at the time of its removal.

The process of dismantling a double girder overhead crane includes several stages:

The operator's cabin is being removed;

The motors responsible for moving the bridge are removed;

Dismantling of crane-beams, as well as single-beam cranes, is carried out in the following sequence:

All elements to be removed are carefully lowered and stored in a previously prepared space.

In case of disposal, they are cut into small components, more convenient for lowering and transportation.

Approximate cost of services for dismantling overhead cranes, as well as crane beams

Price for dismantling an electric overhead crane*:

|

Load capacity |

span |

Price |

|

From 1 to 2 tons |

Up to 15 meters |

From 100,000 rubles |

|

From 3 to 5 tons |

Up to 15 meters |

From 1 5 0 000 rubles |

|

From 6 to 10 tons |

Up to 15 meters |

From 180,000 rubles |

Price for dismantling an electric support crane*:

|

Load capacity |

span |

Price |

|

From 1 to 2 tons |

Up to 15 meters |

From 8 5 000 rubles |

|

From 1 to 2 tons |

Up to 22.5 meters |

From 12 5,000 rubles |

|

From 3 to 5 tons |

Up to 15 meters |

From 12 5,000 rubles |

|

From 3 to 5 tons |

Up to 22.5 meters |

From 14 5,000 rubles |

|

From 6 to 10 tons |

Up to 15 meters |

From 150,000 rubles |

|

From 6 to 10 tons |

Up to 22.5 meters |

From 160,000 rubles |

*The exact cost is determined after our specialists familiarize themselves with the technical specifications and inspect the crane.

Dismantling of gantry cranes

All stages of dismantling a gantry crane are carried out according to a plan drawn up in advance by specialists, which must include such items as:

Creation of a work permit for crane dismantling

The tap is completely de-energized;

The cargo trolley is being removed;

The bridge part is being removed;

The end beams are being dismantled.

Cable routes are dismantled;

Scrap metal or major repairs;

The process of dismantling the structure on the ground completes the work. Remove the engines, movable carriages, supports and other remaining elements.

The cost of dismantling a gantry crane depends on several factors: the weight and design of the equipment, work conditions, accessibility of the installation site. The purpose of disassembling the lifting equipment is also taken into account: for further installation and use or sending for disposal. The cost of dismantling starts from 350,000 rubles per unit.

Specific prices depend on factors such as the weight of the structure, work conditions, and accessibility of the installation site. In addition, the cost of services is directly influenced by the purpose of dismantling. Disassembly and subsequent disposal will always be cheaper.

Application of new technological solutions and modern lifting equipment ensures the shortest possible turnaround time, which will save your enterprise from long forced downtime.

Dismantling of crane tracks

Work on dismantling crane tracks is most often carried out using special lifting equipment. In some cases, you can get by with cargo winches and jacks.

The procedure includes the following necessary steps:

Dismantling of ground tracks (immediately before dismantling, it is necessary to turn off the power supply, then remove the stops and fences, and then dismantle the sleepers, half-sleepers and rails; when completely dismantling the tracks, the ballast cushion is also removed and the earthen layer is completely leveled);

Removal of overhead tracks (whether done manually or using truck cranes, requires work at height; first the power supply is turned off, then the rails and crane beams are removed, carefully lowered to the ground, and then either marked or cut for disposal ).

The cost of dismantling crane tracks starts from 300 rubles/running meter.

The work of dismantling cranes, crane tracks and crane beams is carried out by industrial climbers with extensive experience. We use special tools, as well as safety and rigging equipment specifically designed for such work.

To order or send terms of reference on This address email protected from spam bots. You must have JavaScript enabled to view it. or call 8-495-236-74-30

The work project was developed for the full scope of work for the dismantling of two KM-10 overhead cranes in span I-K and one overhead crane (KM16/3.2) in span 0/1-0/7 of the facility: “Building of shopping and entertainment complex.”

The initial data for the development of the PPR were:

Customer's assignment for project development;

Technical report on the results of a technical inspection of the main building structures

Design and estimate documentation;

STO NOSTROY 2.33.52-2011 “Organization construction site. New construction."

SNiP 12-01-2004 “Organization construction production»;

Government Decree Russian Federation dated April 25, 2012 No. 390 “Fire regulations in the Russian Federation”

N123 Federal Law of the Russian Federation Technical regulations on fire safety requirements.

SP 4.13130.2013 “Fire protection systems. Limiting the spread of fire at protection facilities. Requirements for space-planning and design solutions"

PUE-issue 7 “Rules for electrical installations”;

SNiP 12-04-2002 “Labor safety in construction”;

SNiP12-03-2001 “Labor safety in construction”;

PB 10-382-00. “Rules for the design and safe operation of load-lifting cranes”

SNiP P-12-77 “Noise Protection”

SP 2.2.3.1383-03 “Hygienic requirements for the organization of construction production and construction work”;

List of structures to be dismantled

At the facility being designed, two KM-10 overhead cranes with a lifting capacity of Yut in span I-K and one overhead crane KM-16/3.2 with a lifting capacity of 16 tons in span 0/1-0/7 are dismantled.

Instructions for carrying out work

Work on dismantling overhead cranes must be carried out by specialized construction organization licensed to perform this type of work.

Dismantling the cranes should be done in the reverse order of its construction.

Work on the dismantling of two overhead cranes in span I-K is carried out using a KS-6478 truck crane with a lifting capacity of 50 tons and a telescopic boom, and the dismantling of an overhead crane in span 0/1-0/7 is carried out using two three-scissor lifting tables with a lifting capacity of 10.0 tons each. and a lifting height of 10m and an electric winch TEL-10-1.

Dismantling of two KM-10 overhead cranes in span I-K

- a) determine the installation location;

- b) install a warning fence in the dangerous area of the crane;

- c) cut off power to the trolleys.

Dismantling the crane beams is carried out in the following technological sequence:

Install the faucet.

Using a truck crane, dismantle the cargo trolley;

General information (end)

Sling the overhead crane by securing hemp ropes at the four ends of the bridge (see PPR-5);

Using a truck crane, raise the crane bridge by 20 cm to make sure the sling is secure, then rotate the body of the crane bridge 90 degrees and slowly lower it into the car body. When lowering the bridge, keep it from swinging and turning with the help of four hemp ropes.

Dismantling of the cranes is carried out by a team of installers of six people (see construction plan and work schedule)

Dismantling of the KM-16/3.2 overhead crane in span 0/1-0/7

Before starting work on dismantling overhead cranes, it is necessary to complete:

a) determine the installation location;

b) install a warning fence in the dangerous area of the crane;

c) cut off power to the trolleys.

Dismantle the overhead crane in the following technological sequence:

Install two three-scissor lift tables (load platforms) model SMG with a lifting capacity of 100 m and a lifting height of 10 m, serving as a means of scaffolding and as jacks for lowering beams;

Using two lifting tables, the crane is raised 10cm;

Using an autogen and a grinder, both support units of the bridge crane are cut off and lowered down using the TEL-10-1 electric winch and a block installed on the rafter beam;

Using two three-scissor lift tables, the two beams of the overhead crane are lowered down;

Using a truck crane, the bridge beams of the overhead crane are individually slung and loaded into the vehicle body;

Dismantling of the overhead crane is carried out by a team of installers of six people (see construction plan and work schedule)

Guidelines for safe work practices

The adopted organizational and technological scheme for dismantling fully ensures safe working conditions for workers on the construction site, due to:

- Selection of mechanisms and load-handling devices.

- Limitations of areas for carrying loads by crane.

- Choosing safe work methods.

- Selection of scaffolding means.

Besides:

According to current legislation Responsibilities for ensuring safe labor protection conditions at the construction site are assigned to the employer, and the following should be done:

- When performing construction and installation work, the requirements of SNiP 12-04-2002 and SNiP 12-03-2001 “Occupational Safety in Construction” must be observed.

- Dismantling of structures is carried out under the direct supervision of an engineer and technical worker appointed by order of the organization.

- Workers are allowed to work after being briefed at the workplace on labor safety, taking into account the specifics of dismantling a building of this design.

- All construction workers must be provided with personal protective equipment.

4. When lifting dismantled structural elements, the vertical position of the cargo ropes must be ensured; for this purpose, universal traverses are used. It is not allowed for the crane to pull out pinched slings and ropes, lift structures that are not completely freed from connections, or pull them back during lifting, moving and lowering.

6. Dangerous areas are fenced with a signal-type fence 1.2 m high in accordance with GOST 23407-78, which ensures that unauthorized persons are not allowed to enter the hazardous areas.

7. Illumination of the work area is provided with PZS-35 type floodlights installed on the structures of the existing building, based on illumination of 2 lux. - PB 10-382-00. “Rules for the design and safe operation of load-lifting cranes”

8. Operation of lifting machines is carried out in accordance with the “Rules for the design and safety

operation of load-lifting cranes"

9 Ensure electrical safety at the construction site in accordance with the requirements of PUE issue 7

“Rules for electrical installations” and GOST 12.1.013-78 “Construction. Electrical safety".

10. In order to reduce noise, both on the construction site and beyond. PPR recommends using electric and pneumatic tools with low noise characteristics.

11. Sanitary premises must be equipped in accordance with the hygienic requirements for the design and equipment of premises for workers in construction and installation organizations, approved by the Ministry of Health, and must meet fire safety standards.

12. At the construction site there must be first aid kits with medicines, a stretcher, a set of fixing splints and other means for providing first aid.

13. At all work sites where this is required by working conditions, near equipment, machines and mechanisms, on highways and other dangerous places, post clearly visible dark time days, illuminated warnings and safety signs, posters and safety instructions.

List of design solutions and measures to ensure fire safety during construction

When organizing a construction site and conducting construction and installation work, strictly follow the Decree of the Government of the Russian Federation of April 25, 2012 No. 390 “Fire regulations in the Russian Federation.” “Technical regulations on fire safety requirements N 123 Federal Law of the Russian Federation”, SP 4.13130.2013 “Fire protection systems. Limiting the spread of fire at protection facilities. Requirements for space-planning and design solutions” and these instructions.

1. The project provides access to both temporary and existing buildings and structures under construction. The entrance to the building under construction complies with clause 8.3 “c” of SP 4.13130.2013.

2. At the entrance to the construction site, it is planned to install a board with a fire protection plan showing buildings and auxiliary buildings and structures under construction, entrances, entrances, the location of water sources, fire extinguishing equipment and communications.

3. By the start of construction, the construction site must be provided with fire-fighting water supply (existing fire hydrants) and household supplies.

Description of solutions for waste removal and disposal

Before recycling various elements, materials and waste, they must be sorted and the issue of their use must be resolved.

Metal elements: beams of overhead cranes - used in the construction of temporary buildings and structures, for low-rise construction and agricultural construction. Small-sized rolled metal products are sold to Vtorchermet enterprises.

Rolled metal from the dismantling of overhead cranes is transported by the contractor to specially designated areas.

Instructions for the construction plan

Stroygenplan was developed for the period of dismantling of two overhead cranes with a lifting capacity of UT in the span "I" - "K" and one overhead crane with a lifting capacity of 16 tons in the span "0/1-"0/7" of the object: "The building of a shopping and entertainment complex (completion construction of an unfinished object) on the street. Shchorsa, 66 in Kirov"

The construction master plan reflects:

dismantling of two overhead cranes in the I-K span is carried out using a truck crane brand KS-6478 with a lifting capacity of 50 tons with a telescopic boom. The selection of the crane is made based on the dimensions and design of the building, technical specifications crane

and conditions for transporting the crane. Dismantling of a crane with a lifting capacity of 16 tons in span 0/1-0/7 is carried out using two lifting tables (loading platforms) with a lifting capacity of Yut and a lifting height of up to Yum and an electric winch with a lifting capacity of 5.4 t brand TE/1-10-1

- fencing of hazardous areas is provided as a signal type according to (GOST 23407-78) with a height of 1.2 m;

- access and temporary roads inside the building are designed on the existing concrete surface;

- temporary sidewalks are made of planks 600mm wide and 40mm thick;

- Temporary power supply is designed from the existing ASU. Temporary electrical wiring at the construction site should be carried out using an electric cable or an insulated wire suspended at a height of 2.5 m above workplaces, 3.5 m above passages, and above passages. Boxes with electric switches should be equipped with casings and hung in locked boxes. Domestic premises should be connected to power lines using RCD devices;

- the boundaries of the dangerous zones of the crane are drawn - taking into account the limitation of the transfer of loads by the crane both horizontally and vertically;

- illumination of workplaces and passages is provided with floodlights of the PZS-35 type.

When carrying out work on organizing a construction site, be guided by the requirements of SNiP 12.01-2004 “Organization of construction production”, SNiP 12-03-2001 part 1 “Labor safety in construction”, - Decree of the Government of the Russian Federation of April 25, 2012 No. 390 “Fire safety rules in RF." - N123 Federal Law of the Russian Federation Technical regulations on fire safety requirements. SP 4.13130.2013 "Code of rules. Fire protection systems" and "Calculation standards for drawing up construction organization projects."

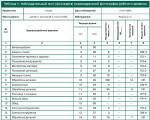

The need for machines, mechanisms, equipment, fixtures and tools |

||||

|

N n\n |

Name |

technical character |

brand |

quantity |

|

Truck crane |

<3=50т;телеск. |

KS-6478 |

||

|

Universal traverse for mounting beams and trusses 10 m long |

Q=25.0t |

TsNIIOMTP R.Ch. 089 000 |

||

|

Loop towel sling STP 15.0/3000 t/mm |

Q=15.0t L=3.0m |

SKP15/3.0 |

||

|

Electric winch with 250m cable reserve |

TEL-10-1 |

|||

|

Manual lever winch with 20m cable reserve |

P=5.4t |

JM-5.4 |

||

|

Overpass for loading vehicles |

||||

|

Heavy duty container |

3.0x5.0 |

|||

|

Flatbed vehicles |

PC |

|||

|

Arc welding machine |

PC |

TS-500 |

||

|

Gas cutting device. |

PC |

|||

|

Three-scissor lift table (lifting platform) |

H = 10m Q=10.0t |

model |

||

|

Bulgarian |

PC |

250mm |

||

|

Prefabricated scaffolding |

set |

|||

|

Hanging block |

PC |

|||

|

Double-loop lanyard (universal) |

L=4.0m |

SKP 1-4.0 |

||

|

Standard kit for installation work |

set |

|||

Dismantling a gantry crane includes dismantling metal structures and crane tracks, removing equipment and disconnecting mechanisms. In the simplest cases, dismantling work consists of collapsing the crane and then cutting it up and removing the remaining construction waste. In this case, the area at the site of the collapse is thoroughly cleaned, and the crane is attached to the bulldozer using cables. After this, the metal is cut using hydraulic shears, and the resulting pieces are sent for processing.

When does the need to dismantle a gantry crane arise?

Dismantling of gantry cranes is necessary in several cases:

- worn out or faulty equipment needs to be replaced;

- it is necessary to replace outdated mechanisms with newer analogues;

- gantry crane needs repair;

- a decision was made to demolish the crane;

- the crane needs to be transported to another location.

Dismantling a gantry crane is much faster than installing it. However, not in all cases the method of simple dumping with a bulldozer is used. If the crane will continue to be used, there is not enough space to collapse it, and there are buildings or power lines nearby, then you need to call a team of specialists who will dismantle the structure step by step.

Features of dismantling a gantry crane

To dismantle the gantry crane, lifting equipment must be used. Light cranes can be disassembled quickly and easily, but for more massive and complex structures it is necessary to attract an additional team of workers. In addition, an experienced electrician must be involved in the dismantling process.

The steps to dismantle a gantry crane include:

- dismantling of electrical equipment and cable routes under the supervision of an electrician;

- removing the control cabin using a crane;

- dismantling the cargo trolley;

- removing equipment from the span;

- gradual disassembly of the crane itself - unscrewing the bolts on the support connections, dismantling the supports, etc.

To ensure a high level of safety, all work on dismantling the gantry crane must be supervised by specialists and carried out using two truck cranes. Craftsmen who carry out dismantling must have appropriate documents giving them the right to carry out this type of activity.

Gantry crane dismantling cost

The main feature of the installation and disassembly of a gantry crane is that this design is used in the construction of residential and industrial buildings, at railway stations, warehouses, open bases, industrial sites and other places where continuous production is established. This means that the dismantling of the gantry crane must be carried out quickly and efficiently in order to minimize losses during production downtime.

The price for dismantling a gantry crane includes the use of heavy equipment and payment for the work of a team of specialists. The cost of services depends on the complexity of working conditions and the time allocated for dismantling the crane. In addition, the price of dismantling work will be higher if you need to carefully and quickly disassemble a structure that will be used in the future. And, accordingly, dismantling a gantry crane with an expired service life using the collapse method will cost much less.

Many production organizations have had gantry cranes since Soviet times, which are no longer used for their intended purpose, but have not been dismantled. These giants pose a potential threat, since over time tired metal can simply deform, which can lead to an emergency and even loss of life.

Only qualified specialists should dismantle gantry cranes, as this complex task cannot be trusted to untrained workers. Our company offers a service for dismantling gantry cranes. Moreover, all work will be carried out in compliance with all regulatory requirements.

Dismantling of gantry cranes for scrap metal

Quite a lot of old, worn-out gantry cranes, reloading and construction cranes are used at industrial facilities. Reloading stations have a small height and a fairly small load capacity, due to which their disassembly is carried out quickly and without the involvement of large-capacity specialized equipment. The situation is completely different with building and installation structures. Their disassembly involves the use of special technological techniques, with the help of which the work is carried out quite quickly and accurately.

Procedure for disassembling a gantry crane

When dismantling a gantry crane, first of all, preparatory measures are carried out, including the development of a project. The project indicates all possible nuances of the disassembly procedure: the type and quantity of special equipment used, the timing of dismantling, the number of qualified workers involved and a step-by-step plan for completing the work.

During the dismantling process, special attention is paid to safety and mandatory fencing of the work area is carried out.

The dismantling process itself consists of the following stages:

Turning off the power supply and removing electrical equipment.

The operator's cabin, cargo trolleys are dismantled and all additional equipment is removed.

The crane is lifted using pneumatic devices and the support legs are trimmed.

The crane body is lowered onto the prepared site.

The body is cut and individual parts are transported to the storage location.

Why choose our company to dismantle gantry cranes?

Our company has extensive experience in this field of activity and therefore specialists work according to proven technological schemes that exclude emergency situations.

Thanks to the availability of all specialized technical means, dismantling work is carried out within the allotted time frame and at the same time the highest level of safety is ensured.

For this reason, our company is the leading organization to which representatives of many industrial enterprises turn. Another important aspect is that we have a flexible pricing policy, making our services available to both large industrial enterprises and small companies. It is also important to note that the dismantled crane is sent for re-melting and, accordingly, brings its owner significant income, which can almost completely cover the costs of dismantling work.

Cost of dismantling gantry cranes

| Name | Price rubles per ton | |||

|---|---|---|---|---|

| Dismantling of gantry cranes | ||||

| Simple dismantling work | from 1000 rub. | |||

| Complex dismantling work | from 2000 rub | |||

| Plasma cutter (non-ferrous metals no more than 40mm thick) | from 700 rub | |||

| Complete dismantling (including structural cleaning services, cleaning and garbage removal, services of slingers, riggers) |

from 1500 rub | |||

| Garbage removal (from 8 cubic to 27 cubic containers) | from 5000 rub. | |||

| Removal of metal (1 worker) | from 1500 rub/shift | |||

We provide services in the following cities

|

Arkhangelsk |

Volgograd |

Kislovodsk |

Nizhny Novgorod |

Ryazan |

Togliatti |

|

Astrakhan |

Vologda |

Krasnodar |

Eagle |

Samara |

Tula |

|

Belgorod |

Voronezh |

Kursk |

Orenburg |

Saint Petersburg |

Ulyanovsk |

|

Blagoveshchensk |

Ivanovo |

Lipetsk |

Penza |

Saratov |

Ufa |

|

Bryansk |

Kazan |

Magnitogorsk |

Pskov |

Smolensk |

Cheboksary |

|

Veliky Novgorod |

Kaluga |

Moscow |

Pyatigorsk |

Stavropol |

Chelyabinsk |

|

Vladimir |

Kirov |

Murmansk |

Rostov-on-Don |

Tver |

Yaroslavl |

Purpose of dismantling

Depending on the purpose of dismantling work, the order of its implementation is determined.

Disposal of lifting equipment.

Further operation: major repairs, relocation (relocation of the gantry crane) to a new location, reconstruction of equipment, etc.

In the first case, when the crane is to be scrapped, a more effective and efficient dismantling method can be used. The gantry crane is “filled up” using a bulldozer:

Overturning - if the supports are rigidly connected to the span structure. It is necessary to first prepare and fence off the area where the crane fell.

Folding - first loosen the fasteners of the bridge with the supports and, hooking it with a cable, “fold” the crane, calculating its fall in a given direction.

On the ground, all metal structures are cut, assembled and transported for disposal.

The specialized company "TehKranMontazh" will dismantle the gantry crane in a short time, carefully, in compliance with the requirements

FNP "Safety rules for hazardous production facilities that use lifting structures" dated November 12, 2013 and RD 22-28-37-02.

Thanks to extensive experience, TechKranMontazh specialists have developed universal technologies for dismantling lifting equipment of any type.

Dismantling of gantry cranes taking into account further operation

This type of work is considered the most labor-intensive and is performed in compliance with a strict sequence of actions. The stages of dismantling a gantry crane are carried out in accordance with a pre-drawn up plan, which is developed after inspection and examination of the equipment:

- Development of a work permit for the dismantling of a gantry crane.

- Preparation of supports, sleeper nets, etc. - that is, the platforms where the crane will be lowered.

- De-energizing, disconnecting electrical appliances, dismantling cable routes is carried out by a specialist electrician.

- The preliminary dismantling of the cargo trolley and operator's cabin will allow the weight of the structure to be significantly reduced. They are removed using truck cranes.

- Loosening of the connections between the crane supports and the span structure. The bridge is first engaged on both sides (near the supports) by truck cranes. After loosening the connections, the span structure is smoothly lowered by truck cranes onto the prepared pylons/supports, while the supports come out from under the bridge due to the movement of wheeled trolleys along the rail track.

The final stage of dismantling a gantry crane is carried out on the ground: dismantling metal structures, disconnecting engines,

Mobile carts, supports, etc., loading and removal of equipment.

The TekhKranMontazh company also provides the following services:

Dismantling of gantry and semi-gantry cranes.

Dismantling of gantry container cranes.

Dismantling of gantry grab cranes

Dismantling of double girder gantry cranes.

Dismantling of single girder gantry cranes.

The cost of dismantling a gantry crane depends on several factors: the weight and design of the equipment, work conditions, accessibility of the installation site. The purpose of disassembling the lifting equipment is also taken into account: for further installation and use or sending for disposal.

“TehKranMontazh” additionally offers the service: transfer/relocation of a gantry crane to parallel rail tracks.

The use of modern technologies and auxiliary lifting equipment allows work to be completed as quickly as possible, without reducing the productivity (no long-term downtime of the PMG) of the enterprise.