Find a job for a 6th grade forest feller. Profession Forest feller (6th category) in the Unified Tariff Qualification Directory. Requirements for a forest feller

Characteristics of the work.

Felling trees, harvesting brushwood, firewood and other assortments from small forests and bushes with gas-powered saws of various types in accordance with established state standards and technical conditions. Cutting down trees and stumps flush with the ground when performing preparatory work on laying skidding trails, logging trails to logging sites, constructing timber loading points and upper timber warehouses. Using gearless gasoline-powered saws, performing a range of work in felling areas for single tree felling, limbing, marking, bucking logs and hilling assortments. Carrying out maintenance and routine repairs of various types of gasoline-powered saws, hydraulic felling wedges and other auxiliary tools, replacing saw chains, cleaning, lubricating and refueling. When felling trees individually, prepare the workplace near the trees being cut down.What you should know:

- device and operating rules for gas-powered saws of various types and a hydraulic felling wedge

- rules and schemes for organizing mechanized development of cutting areas

- rules for selecting trees for cutting

- technical requirements for harvested assortments

- methods for rational cutting of logs into assortments

- rational methods for performing a complex of works on felling trees, pruning branches, marking and bucking logs, hilling assortments

- state standards and technical specifications for timber

- rules for pointing saw chains and other cutting tools

- rules for preparing workplaces at the cutting site.

Logging is a profession that only a real man can master. This job requires remarkable physical strength and well-honed skills. And if the guys shouldn’t have any particular difficulties with the first, then what about the second? Where can I learn basic saw skills? And how difficult is it to master them?

Excursion into history

Let's start with the fact that this is a very ancient work. has always been essential for the survival of humanity. Wood was used to build houses, fortifications, bridges, tools and much more. Therefore, the people have always needed those who can provide them with such a valuable resource.

Naturally, in the old days it was very different from what we are used to seeing today. After all, at that time stone and then bronze axes were used as tools, which greatly slowed down the work. Only half a century before the birth of Jesus Christ, the ancient Greeks forged the first iron saw.

A modern take on felling trees

Continuing the theme of history, let's say that the first chain saw appeared only at the beginning of the 20th century. It was invented by the famous German design engineer Andreas Stihl. According to records, in 1926 he patented a new invention, and in 1929 he produced his first working prototype. And from that time on, felling trees grew into something more than just swinging an ax.

Moreover, with the advent of the new millennium, this process has accelerated significantly. The introduction of new automated saws made it possible to harvest wood with unprecedented productivity. Not to mention the fact that loading and transporting trees is now done exclusively with the help of machines. Consequently, today's lumberjacks must not only have excellent strength and endurance, but also be able to use all these complex mechanisms.

A quick overview of the lumberjack profession

Today, a forest feller is a real one. He knows how not only to cut trees, but also competently plans the entire work process. And this is very important, because in this matter any mistake can lead to irreparable consequences. In this regard, there is a whole set of rules and laws that regulate the actions of this worker.

This also means that everyone who wants to get this job is required to undergo preliminary training. Upon completion, the future lumberjack undergoes certification, which decides his future fate. Please note that employment without proper documents is unacceptable, and in the event of an emergency, such negligence is punished to the fullest extent of the law.

Where can I get a “crust” as a forest feller?

You need to understand: this is a very specific job. A forest feller is a person who knows all the intricacies of his business, is able to account for his actions and take care of those around him. Naturally, such skills will not appear on their own. But they can be taught by teachers and mentors in special preparatory courses. However, there are two ways to get to them:

- Firstly, you can enroll in full-time study at a vocational school or forestry technical school. Often there are separate courses dedicated to felling trees. If there are none, then forestry students are also taught skills in using a chainsaw. True, in this case the training will take a longer period, because you will have to master several professions at once.

- Secondly, there are preparatory courses at most forestries. So, having got a job here, the trainee undergoes preliminary training. He is taught the basics of the craft, told about safety precautions and allowed to try the saw in practice. As a result, at the end of the internship, he passes the certification and receives a certified chainsaw operator.

How is certification carried out?

So, how are a specialist’s skills and work assessed? A forest feller first takes a written exam. All questions are divided into three large categories: the technical structure of chainsaws, methods of felling trees and safety rules. Moreover, at the end of the exam, the commission has every right to ask a few more oral questions.

After passing the written part, you will need to show your practical skills. For example, a person might be asked to make a notch on a training deck or calculate the trajectory of a particular tree to fall.

Classes of forest fellers

According to the new law, only workers with 6th qualification according to ECTS (Unified Tariff and Qualification Handbook) are allowed to fell trees. But at the same time, employees with a much lower rank may also be present at the cutting down. But their capabilities will be greatly limited. In addition, it is often their responsibility to prepare the site, remove garbage, cut down branches and destroy waste.

Naturally, over time the level can be increased. However, in the future, passing the exam for the 6th category the first time is much more profitable than working with a lower rank. After all, not only the prestige of the worker, but also his monthly salary depends on this.

Responsibilities of a 6th category forest feller

The job description of a forest feller always contains a clear list of his responsibilities. And although in some organizations this document has special subparagraphs, their essence often boils down to the following points.

- The forest feller is responsible for bushes and small brushwood in accordance with the standards established by the state. The same rule applies to the sorting of raw materials and the disposal of wood waste.

- One of the primary tasks is preparing the site for felling. At the same time, loggers must do everything possible to provide good access for trawls, as well as to secure it.

- A forest feller must not only be able to handle all types of chainsaws, but also carry out their technical inspection on time. However, if a malfunction or wear of parts is detected, he must immediately notify his mechanic.

- While working, the lumberjack must observe everything that is happening around him, since not only he, but also other people, machinery, and equipment are on the site. Therefore, he is obliged to do everything possible to keep them safe.

- Forestry crew workers must always remember that they can only cut down those trees that the forester has marked. Any manifestation of arbitrariness will lead to penalties that will be applied to the entire team of lumberjacks.

Requirements for a forest feller

Working as a lumberjack requires brute physical strength. Without it, a person simply cannot cut down trees, since the lightest chainsaw weighs at least 4.5 kg. At the same time, most forestries use much larger models, because they allow increasing labor productivity.

In addition, the applicant for the position of forest feller must be of age. And immediately before employment you will need to undergo a standard medical examination. And only after its approval can a person be approved for this position.

Benefits of work

The main advantage is the high demand, justified by the complexity of the work. This is especially true for those regions of Russia where the logging industry is well developed. It is also important that the relevance of this profession will not fade in the near future, since wood is one of the most important materials.

In addition, it should be noted that forest fellers receive a fairly good salary. The average of their salaries in Russia ranges from 35-40 thousand rubles per month. If we talk about work in the North, then here this figure increases by 1.5-2 times.

Disadvantages of the profession

First of all, you need to understand that this profession is very draining on a person’s health. Constant vibrations from chainsaws have a negative impact on the joints of your arms and shoulders. Not to mention the strain it puts on your back and legs.

There is also always a risk that a feller will be injured on the job. It could be a branch that bounced off unsuccessfully, a chain that flew off, or a sharp branch that pierced the shoe. In addition, there are also known cases when people died in clearing. In most cases, this is due to negligence, but sometimes a simple coincidence is to blame.

KOSTROMA REGION

STATE EDUCATIONAL INSTITUTION

PRIMARY VOCATIONAL EDUCATION

PROFESSIONAL LYCEUM No. 23 named after. F.V

Curricula and programs

for professional training of workers

Module by profession - forest feller

Qualification - 6th category

Profession code-11359

Chukhloma, 2009

1. Explanatory note_______________________________________________

2. Professional characteristics______________________________

3.Qualification characteristics_______________________________

4. Working hours in weeks ________________________________________________

5. Structure of the academic year_____________________________________________

6. Curricula_______________________________________________

7. Programs by subject:_____________________________________________

Feller module

8. List of used literature______________________________

9. List of classrooms, laboratories, workshops

EXPLANATORY NOTE

This collection is intended for the professional training of workers in the profession of “Forest feller”.

The collection includes: qualification characteristics, a sample curriculum, thematic plans and programs of subjects of general professional and special courses and industrial training for training workers for the 6th category.

At the end of the collection are sample exam papers.

Training can be carried out both in group and individual methods.

The qualification characteristics are drawn up in accordance with the current Unified Tariff and Qualification Directory of Work and Professions of Workers (issue 37, section “Logging work”, 2001).

Economic training can be carried out according to a variable course, which involves studying one of the subjects that is most suitable for specific conditions: “Economics of the industry and enterprise”, “Fundamentals of ... management”, “Economics of the industry”.

Changes and additions may be made to the thematic plans of the subjects studied, taking into account the specifics of the industry within the hours established by the curriculum.

Thematic plans of the programs are approximate and the right to specific distribution of hours for theoretical and practical classes on topics within the total amount of hours allocated for the subject by the curriculum is granted directly to teachers, who independently choose the forms and methods of conducting classes.

Changes, adjustments or the need to study individual topics of the programs are considered by the methodological association and approved by the deputy for educational and methodological work of the lyceum

When preparing workers, practical training primarily involves practical training at an enterprise.

The industrial training master must train workers in the effective organization of labor and the use of new equipment and advanced technologies at each workplace and site, and discuss with them in detail ways to increase labor productivity and measures to save raw materials, energy, and preserve material assets.

During the training process, special attention should be paid to the need to firmly assimilate and comply with all labor safety requirements and rules. In these

purposes, the teacher of theoretical and master of industrial training, in addition to studying the general rules on labor safety provided for by the programs of theoretical and industrial training, must, when studying each topic or when moving to a new type of work in the process of industrial training, pay significant attention to the rules of labor safety that must be observed in in each specific case.

By the end of the training, each student must be able to independently perform all the work provided for by the qualification characteristics and standards established at the enterprise.

Students are allowed to perform work independently only after passing the occupational safety test.

Qualification exams are conducted in accordance with the Regulations on the procedure for certification of workers in various forms of training. In this case, qualifying (trial) work is carried out at the expense of the time allocated for on-the-job training.

Updating the technical and technological base of modern production requires the systematic inclusion of educational material in existing programs

new equipment and technology, improving product quality, advanced techniques and methods of work, eliminating outdated educational material, terms and standards.

Programs should also be supplemented with economic-specific information.

QUALIFICATIONS

Profession- Forest feller

Qualification- 6th category

Forest feller should know:

Design and operating rules for gasoline-powered saws of various types and a hydraulic felling wedge;

Rules and schemes for organizing mechanized development of cutting areas;

Rules for selecting trees for cutting;

Technical requirements for harvested assortments;

Methods for rational cutting of logs into assortments;

Rational methods for performing a set of works on felling trees, pruning branches, marking and bucking logs, hilling assortments;

State standards and technical conditions for timber;

Point rules for saw chains and other cutting tools;

Rules for preparing workplaces at the cutting site;

Rules for occupational safety, industrial sanitation, electrical and fire safety.

Forest feller must be able to :

Carry out felling of trees, procurement of brushwood, firewood and other assortments from small forests and bushes with gas-powered saws of various types in accordance with established state standards and technical conditions;

Cutting down trees and stumps flush with the ground when performing preparatory work on laying skidding roads, logging trails to logging sites, constructing timber loading points and upper timber warehouses;

Using gearless gasoline-powered saws, carry out a complex of works in felling areas for single tree felling, limbing, marking, bucking of logs and hilling of assortments;

Carry out maintenance and routine repairs of various types of gasoline-powered saws, hydraulic felling wedges and other auxiliary tools, replacement of saw chains, cleaning, lubrication and refueling;

When felling trees individually, prepare a workplace near the trees being cut down;

Observe labor safety rules, industrial sanitation, use fire extinguishing equipment, and provide first aid in case of emergency.

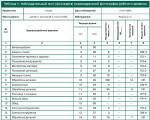

Sample curriculum for professional training in the profession “Forest feller”, 6th category

| Duration of training 9 months | Duration of training 1 year |

||||||||

| No. | Items | Just an hour | Including theory | Including LPZ | Including independent... work | Total hours | Incl. theory | Incl. LPZ | Including independent... work |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 1 | Mechanisms, tools and devices used for felling timber, incl. | ||||||||

| 2 | LPZ Maintenance and repair of chainsaws | 36 | 20 | ||||||

| 3 | | 36 | 36 | 36 | |||||

| 4 | Industrial training, incl. | 246 | 188 | ||||||

| training workshop | 18 | 18 | 36 | 36 |

|||||

| training cutting area | 76 | 76 | 76 | 76 |

|||||

| independent work | 152 | 152 | 76 | 76 |

|||||

| Total | 318 | 54 | 18 | 246 | 264 | 56 | 20 | 188 |

|

THEMATIC PLAN AND PROGRAM

Subject "Mechanisms, tools and devices used in felling

Forests"

| | |

||||||

| No. | Topics | Number of hours | In t h Theory | Incl. LPZ | Number of hours | In t h Theory | Incl. LPZ |

| 1 | General information about mechanisms, tools and devices used in felling forests | 2 | 2 | 2 | 2 | ||

| 2 | The device of gasoline-powered saws | 10 | 4 | 6 | 10 | 4 | 6 |

| 3 | Devices used when felling trees | 6 | 2 | 4 | 6 | 2 | 4 |

| 4 | Preparation of gasoline-powered saws and felling devices for work and their operation | 10 | 6 | 4 | 10 | 6 | 4 |

| 5 | Maintenance of gasoline-powered saws and felling devices and their current repairs | 6 | 4 | 2 | 8 | 4 | 4 |

| 6 | Preparing saw chains for work | 2 | 2 | 4 | 2 | 2 |

|

| Total | 36 | 18 | 18 | 40 | 20 | 20 |

|

PROGRAM

Topic 1. General information about mechanisms,

tools and

devices;

used for felling timber

Classification of mechanisms - tools and devices used in felling timber.

Petrol-powered saws of various types of domestic and foreign production.

Felling tools and devices.

Topic 2. Construction of gas-powered saws

Engine. Device and workflow. Cylinder and piston group. Crank mechanism, crankcase. Engine power system. Carburetor. Carburetor adjustment. Fuel tank, carburetor protection. Features of the power system operation in winter and summer seasons. Checking the serviceability of the carburetor. Ignition system. Spark plug. Contact magneto. Adjusting the contact magneto. Checking the serviceability of the contact magneto. Contactless magneto. Checking the ignition timing of a contactless magneto. Engine cooling system. Clutch. Saw apparatus and saw chain lubrication system. Saw chain, guide bar, drive sprocket. Used saw chains. Control system and vibration protection.

Distinctive features of the design of gearless and geared chainsaws.

Petrol-powered chain delimber. Device. Operating principle.

Familiarization with the design of all available saws of domestic and foreign production by disassembling saws into components and parts.

Topic 3. Devices used when felling timber

Felling hydraulic wedge. Purpose, technical characteristics, operating principle.

Jack. Device, purpose, principle of operation.

Winches for removing hanging trees. Design features, operating principle.

Felling forks, wedges, blades and other felling devices.

Laboratory and practical classes

Familiarization with the design of a felling hydrocline. Disassembly and assembly of felling devices.

Topic 4. Preparing gas-powered saws

and felling devices for work

and their exploitation

Rules for depreservation of gasoline-powered tools. Preparing him for work. Checking the completeness and serviceability of the tool. Refilling the gas tank and oil tank.

Features of starting and stopping the engine for geared and gearless saws. Engine operating mode;

Running in gasoline-powered tools. Adjustment work at the end of the run-in.

Carrying out daily preventive maintenance.

Rules for sawing wood with a gas-powered saw. Techniques for working with gearless saws. Features of operating gas-powered saws at low temperatures

Preparing felling devices for work. Installation and checking of working fluid pressure in hydraulic systems of devices. Operation of the felling hydraulic wedge.

Preservation of instruments and devices.

Laboratory and practical classes

Familiarization with the rules for depreservation of instruments.

Checking the technical readiness of the motor tool. Familiarization with the rules for starting and stopping the engine and running in tools.

Familiarization with the rules for preserving instruments.

Topic 5. Maintenance of gasoline engines

saws and felling devices and their

current repairs

The need for maintenance of saws, tools and accessories. Daily maintenance of gas-powered saws and felling saws

devices. List of operations. Partial scheduled maintenance of gas-powered saws, their frequency.

The main malfunctions of gas-powered saws, eliminated by the feller, directly at the cutting site. Methods for their detection and elimination.

Types of simple metalwork work (marking, straightening, chopping and bending metal, cutting, grinding, drilling, countersinking, threading, riveting, soldering, scraping and lapping of parts), their purpose. Requirements for the quality of locksmith work. Equipment and tools used in the repair of gasoline-powered saws and felling devices. Their characteristics, design features and scope of application.

Laboratory and practical classes

Familiarization with the main malfunctions of gas-powered saws and methods for detecting them.

Topic 6. Preparing saw chains for work

Classification of saw chains. Technical characteristics of saw chains. Saw chain teeth, types and purpose. Basic geometric parameters of saw chain teeth.

Re-preservation of the saw chain. The procedure for running in the saw chain. Adjusting saw chain tension during operation. Replacing the saw chain.

Control of geometric parameters of the saw chain.

Sharpening saw chains. Point rules for saw chains and other cutting tools. Machines and tools for sharpening saw chains. Rules for working on sharpening machines and features of their operation. Sharpening quality control. Editing the saw chain with a file. Classification of files. Jointing of teeth and reduction of saw chain tooth feed limiters.

Saw chain malfunctions. Their identification and elimination. Tools for monitoring the condition of the saw chain.

Saw chain operation in winter. Storage and preservation of saw chains. Improving the reliability of saw chains.

Consumption rates for saw chains for felling and cutting wood.

Laboratory and practical classes

Familiarization with the rules of saw chain points; arrangement of sharpening machines and quality requirements for work performed.

THEMATIC PLAN AND PROGRAM

Occupational safety when felling forests with gas-powered saws

| p/p p/p | TOPICS | Qty hours | Qty Hours |

| 11 | Occupational safety when felling forests with gas-powered saws | ||

| 22 | Occupational hygiene and industrial sanitation | ||

| 33 | Fire prevention measures | ||

| TOTAL | 36 | 36 |

PROGRAM

Topic 1. Occupational safety when felling timber

gas-powered saws

Current occupational safety and health regulations at work. Responsibilities of administration and workers to comply with labor safety rules.

Industrial and household injuries. The main causes of injuries during forest felling. Types of injuries. Prevention of injuries. The procedure for investigating and recording accidents.

Labor safety during logging operations (when felling trees, when felling dead trees, strongly inclined trees, with rot, grown together at the stump of trees; when cutting branches, when bucking logs) at the forest feller's workplace. Familiarization with the “Rules on labor protection in the forestry, woodworking industries and forestry.”

Responsibility of the administration and workers for violation of labor safety rules.

Topic 2. Occupational hygiene and industrial sanitation

General concepts about industrial and personal hygiene and its significance. The importance of correct working posture during work. Rational regime of work and rest. The influence of meteorological environmental factors on the human body.

Occupational diseases and their causes. Preventive measures.

Overalls and personal protective equipment, requirements for them, norms and terms of their wearing, storage.

Self-help and first aid in case of accidents. First aid kit and rules for using it. Transportation of victims.

Topic 3. Fire prevention measures

The main causes of forest fires. Ways to prevent and eliminate them. Fire extinguishing agents, rules for their use.

Fire safety measures at the cutting site.

Extinguishing fires in the forest and rules of conduct for workers in case of fire, in flammable places.

Fire safety rules when working with fuels and lubricants.

Organization of fire protection and fire prevention measures in the forest.

Industrial training

Profession: forest feller

Thematic plan and industrial training program

| No. | 2nd stage, duration of study 9 months | Based on 11 classes, duration of study 1 year |

|

| Topics | Number of hours | Number of hours |

|

| 1 | Training in the training workshop | 18 | 36 |

| 1.1 | Introductory lesson Briefing on occupational safety and fire safety | 2 | 2 |

| 1.2 | Construction of mechanisms and devices used for felling timber | 10 | 22 |

| 1.3 | Maintenance and repair of gas-powered saws | 6 | 12 |

| 2 | Training at the cutting site | 76 | 76 |

| 2.1 | Mastering the techniques and types of work performed by a forest feller (training cutting area) | ||

| 3 | Independent performance of work as a 6th category forest feller. Qualifying trial work | 152 | 76 |

| Total | 246 | 188 |

PROGRAM

I. TRAINING IN THE TRAINING WORKSHOP

Topic 1. Introductory lesson. Instruction on

labor safety and fire

security

Familiarization with the qualification characteristics and industrial training program for this profession.

Instruction on occupational safety, electrical and fire safety in the training workshop.

Familiarization with the operating hours and internal regulations in training workshops.

Topic 2. Mechanical work

Familiarization with equipment for performing plumbing work. Marking, straightening, cutting, bending various metals.

Acquiring practical skills to perform these works and checking their quality.

Metal cutting. Filing it. Other types of locksmith work. Acquiring practical skills.

Processing of parts and workpieces, including various types of work during the repair of gas-powered saws.

Topic 3. Construction of mechanisms, tools and

devices used for felling trees

Instruction on the organization of the workplace and labor safety when studying the mechanisms, tools and devices used in felling forests. Familiarization with the design of all available gas-powered saws of domestic and foreign production. Study of the main nodes. Acquiring practical skills in adjusting the carburetor, the gap between the spark plug electrodes and saw chain tension. Disassembling and assembling a gas-powered saw, checking and determining its serviceability.

Familiarization with the design of a felling hydrocline.

Acquiring practical skills in sharpening saw chains, jointing teeth and reducing tooth feed limiters. Replacing faulty saw chain links.

Topic 4. Maintenance and repair

gasoline saws

Instruction on workplace organization and labor safety during repair work.

Familiarization with the operations of daily and partial scheduled maintenance of a chainsaw and hydraulic wedge.

Chainsaw repair training.

Participation in the ongoing repair of one of the gasoline-powered tools.

P. TRAINING AT THE LOGGING AREAS

Topic 1. Mastering techniques and types of work,

carried out by a feller

(training cutting area)

Instruction on workplace organization and occupational safety.

Preparing a gas-powered saw. Checking the functionality of the saw, chain, power system.

Filling the saw with fuel mixture and oil. Starting the saw engine. Checking engine operation. Regulation of power and ignition systems. Perform all daily maintenance work on gas powered saws.

Preparing the workplace for felling wood. He sawed the tree. Proceed to cutting down the tree. Cutting down a tree. Installation of a hydraulic wedge, hydraulic jack or felling blade. Finishing the tree. The feller retreats to a safe place. Felling of thick-size, tall, inclined, fused trees. Removing hanging trees

Techniques for pruning branches, cutting down stumps, marking, bucking logs and hilling assortments.

Familiarization with the rational cutting of logs into business assortments, taking into account current GOSTs.

Procurement of brushwood, firewood and other assortments from small forests and bushes.

Topic 2. Independent performance of work

6th category forest feller

Independently, under the guidance of an industrial training master or an experienced forest feller, performing the entire range of work in accordance with the requirements of the qualification characteristics, established technology and technical production conditions, advanced labor methods, production standards and labor safety rules.

Qualification (trial) work.

SAMPLE EXAMINATION TICKETS

Ticket No. 1

1. Classification of mechanisms, tools and devices used in felling timber.

2. The most common chainsaw malfunctions and their elimination.

3. Occupational safety requirements at the forest feller’s workplace.

Ticket number 2

1. Design of a gearless gas-powered saw

2. Preparation of a fuel mixture for a gas-powered saw, taking into account the seasons.

3. Possible consequences of violation of labor safety rules by a worker and his responsibility for these violations.

Ticket number 3

1. Design of a geared gas-powered saw.

2. Checking the technical readiness of the working tool.

3. The influence of a rational work and rest regime on labor safety.

Ticket No. 4

1. Power supply system for the saw motor.

2. Disassemble and assemble felling devices.

3. The influence of meteorological factors on the human body and the connection of these factors with the safety of the forest feller.

Ticket number 5

1. Purpose of the carburetor of a gas-powered saw, checking its serviceability.

2. Preparing the feller's workplace for work.

3. Occupational safety when working with fuels and lubricants.

Ticket No. 6

1. Purpose of spark plugs, contact magneto and checking the serviceability of the contact magneto.

2. Cutting the log into business assortments, taking into account the current GOSTs.

3. Fire safety measures when working in the forest.

Ticket number 7

1. Hydraulic wedge. Device, purpose, principle of operation

2. Preparing for launch and starting the saw.

3. Occupational safety when working with a chainsaw.

Ticket No. 8

1. Jack. Device, purpose, principle of operation.

2. Installing a hydraulic wedge when felling a tree.

3. Injuries during felling and measures to prevent it.

Ticket number 9

1. Winches. Design features. Operating principle, application.

2. Sharpening saw chains, devices and sharpening methods.

3. Safety of work of fellers when felling trees.

Ticket number 10

1. Felling forks, wedges, blades. Their purpose and methods of application.

2. Preparing the workplace when cutting down a tree.

3. Measures to protect the feller when finishing wood.

Ticket No. 11

1. Features of starting and stopping the engine for gearless saws.

2. Action of the felling jack and felling wedge.

3. Protective measures when working with delimbing tools.

Ticket number 12

1. Preparation of felling devices for work; Checking the fluid pressure in the hydraulic systems of forest felling devices.

2. Adjusting the saw chain tension.

3. Precautions when adjusting the spark plug electrode gaps and saw chain tension.

Ticket number 13

1. Preparing the sawing machine for work. Saw machine lubrication system.

2. Adjusting the gap between the spark plug electrodes.

3. Causes of forest fires and measures to prevent them.

Ticket number 14

1. Distinctive features of the design of gearless saws.

2. Sharpening saw chains.

3. Overalls and personal protective equipment for forest fellers.

Ticket number 15

1. The main malfunctions of gas-powered saws and methods for detecting them.

2. Carburetor adjustment

3. Occupational safety when working with abrasive materials while sharpening the saw chain.

Study literature list

Unified Tariff and Qualification Directory of Work and Professions of Workers (UTKS), 2019

Part No. 2 of Issue No. 37 of ETKS

The issue was approved by Resolution of the Ministry of Labor of the Russian Federation dated August 29, 2001 N 65

Forest feller

§ 1. Forest feller of the 6th category

Characteristics of work. Felling trees, harvesting brushwood, firewood and other assortments from small forests and bushes with gas-powered saws of various types in accordance with established state standards and technical conditions. Cutting down trees and stumps flush with the ground when performing preparatory work on laying skidding trails, logging trails to logging sites, constructing timber loading points and upper timber warehouses. Using gearless gasoline-powered saws, performing a range of work in felling areas for single tree felling, limbing, marking, bucking logs and hilling assortments. Carrying out maintenance and routine repairs of various types of gasoline-powered saws, hydraulic felling wedges and other auxiliary tools, replacing saw chains, cleaning, lubricating and refueling. When felling trees individually, prepare the workplace near the trees being cut down.

Must know: design and operating rules for gas-powered saws of various types and a hydraulic felling wedge; rules and schemes for organizing mechanized development of cutting areas; rules for selecting trees for cutting; technical requirements for harvested assortments; methods for rational cutting of logs into assortments; rational methods of performing a complex of works on felling trees, pruning branches, marking and bucking logs, hilling assortments; state standards and technical specifications for timber; rules for pointing saw chains and other cutting tools; rules for preparing workplaces at the cutting site.

Comments on the profession

The given tariff and qualification characteristics of the profession “ Forest feller» serve for tariffication of work and assignment of tariff categories in accordance with Article 143 of the Labor Code of the Russian Federation. Based on the above job characteristics and the requirements for professional knowledge and skills, a job description for a forest feller is drawn up, as well as documents required for interviews and testing when hiring. When drawing up work (job) instructions, pay attention to the general provisions and recommendations for this issue of ETKS (see.

I CONFIRM:

[Job Title]

_______________________________

_______________________________

[Name of organization]

_______________________________

_______________________/[F.I.O.]/

"_____" _______________ 20___

JOB DESCRIPTION

Forest feller 6th category

1. General provisions

1.1. This job description defines and regulates the powers, functional and job responsibilities, rights and responsibilities of a 6th category forest feller [Name of the organization in the genitive case] (hereinafter referred to as the Company).

1.2. A 6th grade forest feller is appointed to the position and dismissed from the position in accordance with the procedure established by the current labor legislation by order of the head of the Company.

1.3. A 6th grade forest feller belongs to the category of workers and reports to [name of the position of the immediate supervisor in the dative case] of the Company.

1.4. A person with secondary vocational education, appropriate training in the specialty and work experience of at least 1 year is appointed to the position of forest feller of the 6th category.

1.5. In his activities, a 6th category forest feller is guided by:

- regulations and methodological materials on the work performed;

- internal labor regulations;

- orders and instructions of the head of the Company and immediate supervisor;

- this job description;

- rules on occupational health, safety, industrial sanitation and fire protection.

1.6. A 6th grade forest feller must know:

- design and operating rules for gas-powered saws of various types and a hydraulic felling wedge;

- rules and schemes for organizing mechanized development of cutting areas;

- rules for selecting trees for cutting;

- technical requirements for harvested assortments;

- methods for rational cutting of logs into assortments;

- rational methods of performing a complex of works on felling trees, pruning branches, marking and bucking logs, hilling assortments;

- state standards and technical specifications for timber;

- rules for pointing saw chains and other cutting tools;

- rules for preparing workplaces at the cutting site.

1.7. During the period of temporary absence of a 6th category forest feller, his duties are assigned to [deputy position title].

2. Job responsibilities

A 6th category forest feller is required to perform the following labor functions:

2.1. Felling trees, harvesting brushwood, firewood and other assortments from small forests and bushes with gas-powered saws of various types in accordance with established state standards and technical conditions.

2.2. Cutting down trees and stumps flush with the ground when performing preparatory work on laying skidding trails, logging trails to logging sites, constructing timber loading points and upper timber warehouses.

2.3. Using gearless gasoline-powered saws, performing a range of work in felling areas for single tree felling, limbing, marking, bucking logs and hilling assortments.

2.4. Carrying out maintenance and routine repairs of various types of gasoline-powered saws, hydraulic felling wedges and other auxiliary tools, replacing saw chains, cleaning, lubricating and refueling.

2.5. When felling trees individually, prepare the workplace near the trees being cut down.

In case of official necessity, a 6th category forest feller may be involved in performing his official duties overtime, by decision of the immediate supervisor, in the manner prescribed by law.

3. Rights

A 6th grade forest feller has the right

3.1. Give instructions and tasks to his subordinate employees on a range of issues included in his functional responsibilities.

3.2. Monitor the implementation of production tasks, timely execution of individual assignments by employees subordinate to him.

3.3. Request and receive the necessary materials and documents related to issues of his activities and the activities of his subordinate employees.

3.4. Interact with other services of the enterprise on production and other issues included in its functional responsibilities.

3.5. Get acquainted with draft decisions of the enterprise management related to the activities of the Division.

3.6. Submit proposals for improvement of work related to the responsibilities provided for in this job description for the manager’s consideration.

3.7. Submit for consideration by the manager proposals on rewarding distinguished employees and imposing penalties on violators of production and labor discipline.

3.8. Report to the manager about all identified violations and shortcomings in connection with the work performed.

4. Responsibility and performance evaluation

4.1. A 6th category forest feller bears administrative, disciplinary and material (and in some cases provided for by the legislation of the Russian Federation, criminal) responsibility for:

4.1.1. Failure to carry out or improperly carry out official instructions from the immediate supervisor.

4.1.2. Failure to perform or improper performance of one's job functions and assigned tasks.

4.1.3. Illegal use of granted official powers, as well as their use for personal purposes.

4.1.4. Inaccurate information about the status of the work assigned to him.

4.1.5. Failure to take measures to suppress identified violations of safety regulations, fire safety and other rules that pose a threat to the activities of the enterprise and its employees.

4.1.6. Failure to ensure compliance with labor discipline.

4.2. The assessment of the work of a 6th category forest feller is carried out:

4.2.1. By the immediate supervisor - regularly, in the course of the employee’s daily performance of his labor functions.

4.2.2. The certification commission of the enterprise - periodically, but at least once every two years, based on documented results of work for the evaluation period.

4.3. The main criterion for assessing the work of a 6th category forest feller is the quality, completeness and timeliness of his performance of the tasks provided for in these instructions.

5. Working conditions

5.1. The work schedule of a 6th category forest feller is determined in accordance with the internal labor regulations established by the Company.

5.2. Due to production needs, a 6th grade forest feller can go on business trips (including local ones).

I have read the instructions ___________/___________/ “__” _______ 20__