Use of alternative fuels on ships. Environmental aspects of the use of alternative fuels on sea and river vessels. Liquefied natural gas

© Tishinskaya Yu.V., 2014

The relevance of this topic is determined by the fact that a ship requires a large amount of fuel for its operation, which has a detrimental effect on the environment, since huge cargo ships annually emit millions of cubic meters of carbon dioxide into the atmosphere, causing enormous harm to the atmosphere and hastening the melting of glaciers at the poles. Also, due to unstable prices for petroleum products and limited reserves of these minerals, engineers are constantly looking for alternative fuels and energy sources.

Global shipping is a major source of pollution as global trade requires huge amounts of oil and other combustible materials for seagoing vessels, but as more attention is paid to reducing CO2 emissions, it is clear that the time has come to make changes to propulsion systems or find replacement for them.

Currently, within just one country, the consumption of motor fuels produced from oil can reach hundreds of millions of tons. At the same time, road and maritime transport are among the main consumers of petroleum products and will remain the main consumers of motor fuels for the period until 2040-2050.

Also, a significant impetus for the development of this issue is the fact that, in accordance with the requirements of the International Convention for the Prevention of Pollution from Ships, there is a systematic tightening of requirements for the content of oxides of sulfur, nitrogen and carbon, as well as particulate matter in emissions from sea-going ships. These substances cause enormous harm to the environment and are alien to any part of the biosphere.

The most stringent requirements are put forward for Emission Control Areas (ECAs). Namely:

· Baltic and North seas

· coastal waters of the USA and Canada

· Caribbean Sea

Mediterranean Sea

· coast of Japan

· Strait of Malacca, etc.

Thus, changes in standards for sulfur oxide emissions from marine vessels in 2012 are 0% and 3.5% in special areas and worldwide, respectively. And by 2020, the standards for sulfur oxide emissions from sea vessels in these areas will similarly be 0%, and worldwide will already drop to 0.5%. This implies the need to solve the problem of reducing chemical emissions of harmful substances into the atmosphere from ship power plants and to search for new, more “friendly” types of fuel or energy for use on ships.

To solve these issues, it is proposed to introduce innovations in two different directions:

1) Use of new, more environmentally friendly and economical types of fuel when operating ships;

2) Refusal from our usual fuel in favor of using the energy of the sun, water, and wind.

Let's consider the first way. The main types of alternative fuels are the following:

Biodiesel is an organic fuel produced from oilseed crops.

The price of branded biodiesel is approximately two times higher than the price of regular diesel fuel. Studies conducted in 2001/2002 in the USA showed that with a fuel content of 20% biodiesel, the content of harmful substances in exhaust gases increases by 11% and only the use of pure biodiesel reduces emissions by 50%;

Alcohols are organic compounds containing one or more hydroxyl groups directly bonded to a carbon atom. Alcohols are prohibited as low flash point fuels;

Hydrogen is the only type of fuel whose combustion product is not carbon dioxide;

It is used in internal combustion engines in pure form or as an additive to liquid fuel. The danger of storing it on a ship and the expensive equipment for such use make this type of fuel completely not promising for ships;

The water-fuel emulsion is produced on the ship in a special installation - this saves fuel, reduces nitrogen oxide emissions (up to 30% depending on the water content in the emulsion), but does not have a significant effect on sulfur oxide emissions;

Liquefied and compressed combustible gases make it possible to completely eliminate emissions of sulfur and particulate matter into the atmosphere, radically reduce emissions of nitrogen oxides by 80%, and significantly reduce emissions of carbon dioxide by 30%.

Thus, it can be argued that the only new type of fuel, the use of which significantly affects the environmental performance of ship engines, is natural gas.

Let's move on to consider the second way. Wind and sun are the most common sources of energy on earth. Many organizations offer all kinds of projects to implement them in everyday life.

In international practice, there are already several implemented and not yet implemented projects of ships using wind and solar energy for their navigation.

In an effort to reduce fuel consumption on large merchant ships in the world's oceans, a group from the University of Tokyo developed the “Wild Challenger” project.

By using giant retractable sails measuring 50 meters high and 20 meters wide, annual fuel consumption can be reduced by almost 30 percent. For maximum thrust, the sails are individually controlled and each sail is telescopic with five tiers, allowing them to be stowed away when the weather turns unfavorable. The sails are hollow and curved, made from aluminum or reinforced plastic, making them more wing-like. Computer simulations, as well as wind tunnel tests, have shown that the concept can operate even in crosswinds. Thus, the “Wind Challenger” project can truly become the development of fuel-efficient ships of the future generation.

The company “Eco Marine Power” has developed a project “ Aquarius", which means "Aquarius". A special feature of this project is the use of solar panels as a sail.

Such sails even received their own name “rigid sail”. They will become part of a large project that will allow sea vessels to easily use alternative energy sources while at sea, in the roadstead and in port. Each sail panel will automatically change position using computer control, which is being developed by a Japanese company. KEI System Pty Ltd" The panels can also be removed during adverse weather conditions.

The latest advances in solar technology mean that a combination of solar panels and sails can now be used, placing this project at the forefront of modern shipbuilding developments.

System " Aquarius» is designed in such a way that it does not require much attention from the ship's crew and is relatively easy to install. The materials from which the rigid sail and other system components are made are recycled.

System " Aquarius» will become attractive for investment by shipping companies and ship operators due to the rapid payback of the project.

We can conclude that both of these ways are designed to solve the same problems. The implementation of these projects has a significant impact on global shipping, contributing to a significant reduction in environmental pollution and reducing fuel and maintenance costs. What to choose is everyone’s business. An easier way for implementation is the use of economical fuel, since this technology does not require a complete replacement of the fleet, but can be used on existing ships, but still maintains a certain level of fuel costs and emissions of harmful substances into the atmosphere. Choosing to build ships that use alternative energy sources in their operation, on the one hand, requires a complete replacement of the fleet, but on the other hand, eliminates fuel costs and significantly reduces various types of environmental pollution.

Literature

1. Sokirkin V.A. International maritime law: textbook / Sokirkin V.A.,

Shitarev V.S. – M: International Relations, 2009. – 384 p.

2. Shurpyak V.K. Application of alternative types of energy and alternative

fuels on sea vessels [Electronic resource]. - Document access mode:

http://www.korabel.ru/filemanager

3. Ships of the future [electronic resource]. – Document access mode:

http://korabley.net/news/korabli_budushhego/2010-04-05-526

4. Economical ships are possible [electronic resource]. – Access mode

document: http://korabley.net/news/ehkonomichnye_suda_vozmozhny/2014-01-06-

5.Alternative Aquarius System Could Change Shipping

[electronic resource]. – Document access mode: http://shipwiki.ru/sovremennye_korabli/na_ostrie_progressa/alternativnaya_sistema_emp_aquarius.html

International initiatives to reduce carbon dioxide (CO2) and other harmful emissions from ships are driving the search for alternative energy sources.

In particular, the report from the classification society DNV GL examines the use of fuel cells, gas and steam turbines together with electric drive systems, which can only be effective in combination with more environmentally friendly fuels.

The use of fuel cells on ships is currently in development, but it will be a long time before they can replace main engines. Concepts in this direction already exist, for example, a ferry from VINCI Energies. Such a vessel has a length of 35 m. It will be able to hold a charge of energy obtained from renewable sources for 4 hours. The company's website says that such a vessel will operate between the French island of Ouessant and the continent starting in 2020.

The use of batteries and wind energy is also considered as innovative technologies.

Wind powered vessel, The Vindskip

Battery systems are already used in shipping, but the use of the technology for marine vessels is limited due to low efficiency.

Finally, the use of wind energy, although not new, has yet to prove its economic attractiveness in modern shipbuilding.

We remind you that from January 1, 2020, the sulfur content (SOx) in fuel should not contain more than 0.5%, and greenhouse gas emissions should be reduced by 50% by 2050, according to the latest decision of the International Maritime Organization (IMO).

Alternative fuels

Alternative fuels currently being considered include liquefied natural gas (LNG), liquefied petroleum gas (LPG), methanol, biofuels and hydrogen.

The IMO is currently developing a safety code (IGF Code) for ships using gas or other environmentally friendly fuels. Work continues in the area of methanol and low flashpoint fuels.

An IGF Code has not yet been developed for other fuel types, which shipowners need to take into account.

Environmental impact

According to DNV GL, LNG emits the least amount of greenhouse gases (the main greenhouse gases being water vapor, carbon dioxide, methane and ozone). However, unburned methane, which is the main component of LNG, creates emissions with 20 times the greenhouse effect of carbon dioxide (CO2 - carbon dioxide).

However, according to manufacturers of dual-fuel engines, the volume of unburned methane in modern equipment is not so large, and their use reduces greenhouse gases in shipping by 10-20%.

The carbon footprint (the amount of greenhouse gases caused by organizational activities and cargo transportation activities) from using methanol or hydrogen is significantly greater than that from using heavy fuel oil (HFO) and marine gas oil (MGO).

When using renewable energy and biofuels, the carbon footprint is smaller.

The most environmentally friendly fuel is hydrogen, produced from renewable energy. Liquid hydrogen may be used in the future. However, it has a fairly low volumetric energy density, which leads to the need to create large storage areas.

Regarding nitrogen emissions, Otto cycle internal combustion engines powered by CNG or hydrogen do not require exhaust gas treatment equipment to comply with the Tier III standard. In most cases, dual-fuel engines operating on the diesel cycle are not suitable to meet the standard.

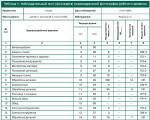

Level of nitrogen emissions when using different types of fuel.

Due to the presence of several power plants on a large ship, for example, the main engine, a diesel generator for generating electricity, a boiler for producing hot water and steam, marine fuel can be represented by several types at once.

Moreover, the main engine of a sea vessel is often powered not by one, but by two or more types of fuel alternately. This is due to the fact that in the ocean there are zones of special control of sulfur emissions - the North and Baltic Seas, the Atlantic and Pacific coasts of the USA and Canada.

When approaching them, the engines are switched to diesel fuel with low sulfur content. The same technique is used before performing maneuvers in which it is necessary to frequently change engine modes. After leaving the port, diesel fuel is replaced with fuel oil, on which the ship travels the main part of the journey.

Shipping fuels

The main types of fuel for ships today are:

- diesel fuel;

- high-viscosity marine fuels;

- other types (KST - component of marine fuel from gas condensate, oil gas turbine TG and TGVK, LNG - liquefied natural gas, etc.)

Diesel and low-viscosity fuels are classified as light petroleum products. They differ from each other in cost (SMT is much cheaper), as well as in technical characteristics.

SMT contains more sulfur (from 0.5 to 1.5% versus 0.01%) and has a lower cetane number (40 versus 45). The main benefit when replacing low-viscosity diesel fuel is that the latter is cheap, and also that in the absence of sulfur, special expensive additives must be added to diesel fuel to maintain lubricating properties.

High-viscosity types of marine diesel fuel are classified as dark grades of petroleum products. They are cheaper than light ones, so they are widely used for shipping. They are divided into light, heavy and extra heavy. These types include naval fuel oils F-5 and F-12, heating oils M-40 and M-100, marine fuel IFO-30, IFO-180, IFO-380. They are produced by mixing residual petroleum products with diesel fractions. Dark grades are used in low-speed and medium-speed engines.

On the storage and preparation of marine fuel

To store fuel on a ship, fuel bunkers are used, located next to the engine room. A large ship can consume up to 40 tons of fuel per day, but excess fuel, with the exception of emergency reserves in case of storms, is not taken on a voyage, since it creates ballast and reduces the useful load of the ship. Ballast also includes dead fuel on a ship - the remains in the bunkers below the intake pipes.

Before use, fuel oils are often subjected to special preparation operations. They consist of:

- In heating the fuel mass of cold fuel oil, which has lost its fluidity, by adding hot fuel oil to the tank. Heating is also carried out in tanks equipped with special heating systems.

- Cleaning by settling or separation in special ship installations; During these processes, dirt, mechanical inclusions and water are separated. Purified fuel wears out engines less, so purification units more than pay for themselves.

Today there are many types of diesel and other types of fuel for ships. To avoid mistakes when purchasing, try to purchase fuels and lubricants only from trusted suppliers.