Presentation for the project “Cheese Tale. Presentation for the project “Cheese Tale What is cheese

Cheese is a food product obtained fromraw milk using

milk-clotting enzymes and

lactic acid bacteria or by melting

various dairy products and raw materials

non-dairy origin using

melting salts.

Nutritional and biological value of cheese

due to the content of a large amount

easily digestible proteins, milk fat,

various minerals, organic

acids and vitamins.

The cheese is rich in calcium and phosphorus salts (100 g of cheese

satisfy a person's daily needs

in calcium).

Cheeses in Holland

Cheese classification:

Technological (same technologicalparameters):

rennet cheeses;

fermented milk cheeses;

processed cheeses.

Commodity classification:

hard cheeses,

semi-hard cheeses,

soft cheeses,

pickled cheeses,

processed (processed) cheeses.

Australian cheeses

Cheese production is conventionally divided into 2 stages:Stage 1 – the entire process of processing milk and curd (up to

molding and salting);

Stage 2 – cheese ripening.

The rennet coagulation process is conventionally divided into

4 stages:

Induction period including

enzymatic stage and latent stage

coagulation;

Mass coagulation stage;

Stage of structure formation and strengthening of the clot

Syneresis stage.

Rennet cheese production technology

acceptance and quality control of raw materials;processing and maturation of raw materials;

normalization and heat treatment of milk;

fermentation, adding calcium chloride,

rennet;

milk curdling;

curd processing;

molding the cheese mass;

self-pressing, pressing and marking;

salting cheese;

cheese ripening;

packaging (or waxing);

marking;

storage and transportation of cheese.

Milk container

Before rolling into cheesenormalized for fat and protein

pasteurized and cooled to

milk is added at a certain temperature

cheese starter, calcium chloride,

biological and chemical components,

used in cheese making.

Coagulation of the normalized mixture into a clot

occurs under the influence of milk-clotting enzymes and lactic acid.

The activity of the enzyme depends on the pH of the milk,

the presence of soluble calcium salts in milk,

coagulation temperature, etc.

In the technochemical laboratory

Under the influence of rennet occursaggregation of paracasein particles and formation

clot.

The coagulation of milk by rennet occurs in

for 20 minutes. at a temperature of 30-32 °C.

Processing the cheese curd

When the curd is processed, whey is released from

clot to a certain level in two stages.

The first stage is the production of cheese grains, in which

serum is released after the clot is cut and

the process of its processing to obtain protein-fat

particles (cheese grains) of a certain size.

The second stage (processing of cheese grains) consists of

additional serum release. Selection

serum at this stage occurs with constant

kneading cheese grains in cheese-making baths at

a certain temperature.

Kneading the clot

In the production of rennet solidscheeses are used after kneading

second heating to enhance

separating whey from cheese grains and

regulation of microbiological

processes.

Apply low temperature second

heating (38-42 °C) or high (48-56

°C). At high temperatures of the second

heating creates preferential

conditions for the development of thermophiles

lactic acid bacteria.

Cheese bath

Shaping, self-pressing and pressing cheese

Molding is carried out for the purpose of joiningcheese grains into a certain monolith

forms, removing excess whey;

Cheeses are produced in various forms:

spherical, rectangular bars, low

and tall cylinders, truncated cones, etc.

After molding, the cheeses are exposed to

of their own weight are self-pressed (soft

cheeses, some semi-hard and pickled)

or pressed into molds under pressure

external loads (hard cheeses).

Cheese pressing

Salting cheese. Salting of cheese is carried out bykeeping heads of cheese (cheese grains) in

solution of table salt, applying salt grounds

or dry salt on the surface of the cheese or adding

cheese grain.

Salting cheese provides additional

serum secretion, affects activity

water and through it influences the development

microorganisms and enzyme activity during

ripening, forms the characteristic taste of cheese,

influences consistency and promotes formation

cheese rinds.

Mass fraction of table salt in mature cheeses

fluctuates 1.2-7.0% depending on the type of cheese.

Proper conduct of the settlement ensures

the required composition of the finished product and

determines the course of maturation.

Salting cheese

Cheese ripening

After salting and drying, the cheeses are placed in specialmaturation rooms.

In these rooms the cheeses are aged at

appropriate temperature and humidity conditions in

for a certain period of time depending on the type

cheese.

Cheeses are ripened on racks at a temperature of 12-16 ° C and

relative air humidity 80-85%.

The duration of ripening varies from several

days (for soft cheeses) up to 2-6 months. (for hard cheeses).

During ripening in the cheese mass the greatest

proteins, milk sugar,

citric acid, partly milk fat.

The continuous ripening process of cheese, in which

there is a reaction that splits the main

components can be roughly divided into two stages:

lactic acid fermentation and enzymatic process.

Cheese ripening

At the first stage, they actively develop within 7-10 days.lactic acid-forming and

flavor-producing bacteria, while milk sugar

almost completely fermented to form

lactic acid.

Endoenzymes (intracellular enzymes), possessing

high proteolytic activity, cause

deep breakdown of proteins (paracasein) to peptones,

peptides, amino acids and even ammonia.

Along with the breakdown of proteins into simpler compounds

free volatile and non-volatile fatty substances are formed

acids, acetic and propionic acids, alcohols,

ethers, aldehydes, diacetyl, acetoin, etc., which

form characteristics characteristic of this type of cheese

organoleptic indicators.

When cheeses ripen, gaseous substances are formed

(carbon dioxide, ammonia, sometimes hydrogen sulfide).

Amount and intensity of carbon dioxide release

are responsible for creating the cheese pattern.

Before packaging

Hard rennet cheeses

Hard cheeses are divided according to size and weight:large;

small

By technology and organoleptic

indicators:

Swiss groups,

Dutch groups,

Cheddar groups

grated cheeses.

Cheeses of the Swiss group: Swiss, Altai, Soviet, Carpathian, Kuban

Cheeses of this group are produced at high temperatures(54-58 °C) second heating of the cheese mass and

using mesophilic and thermophilic

bacterial cultures.

Swiss and Altai cheeses.

Raw materials: high quality milk.

Technology Features:

use of high temperature of the second heating (5458 °C),

prolonged drying of grain (small grain size

about 3 mm),

aging cheese for a month in a fermentation chamber at

temperature 20-25 °C,

long ripening period (from 4 to 6 months) with

temperature 10-12 °C.

Swiss cheese

Taste and smell - pronounced cheesy, slightlysweetish (spicy).

The consistency is homogeneous, lamellar,

related.

The cheese pattern consists of round eyes

or oval shape with a size of at least 10

mm for Swiss and 5-10 mm for

Altai.

The cheeses are shaped like a low cylinder

weighing 50-100 kg (Swiss cheese) and 12-18

kg (Altai cheese).

Mass fraction of fat in dry matter 50%,

moisture - no more than 42%, salt - 1.5-2.0%.

The ripening period of Swiss cheese is 6

months, Altai - 4 months.

Cheeses of the Dutch group - Dutch round and slab, Kostromskoy, Poshekhonsky, Yaroslavsky, Estonian, Stepnoy, Uglichesky, Bukovin

Cheeses of the Dutch group - Dutch round andbar, Kostroma, Poshekhonsky, Yaroslavl,

Estonian, Steppe, Uglich, Bukovinian, and also

low fat cheeses 20-30% (Pribaltiysky,

Lithuanian, Minsk, Vyru, etc.).

Cheese production uses low temperatures

second heating of the cheese mass 37-42 ° C (for fatty ones)

and 35-38 °C or without second heating (for cheeses

low fat content).

The size of the cheese grain is 5-8 mm.

Raw materials - pasteurized milk using

starter cultures from cultures of lactic acid bacteria and

aromatic streptococci.

Cheeses of this group ripen quickly and already at the age of 1 -

2.5 months have a pronounced cheese taste and aroma.

For each cheese, the optimal

moisture content after pressing, salt and level

lactic acid fermentation.

Dutch cheese

Taste and smell - pronounced cheesy, slightlysour.

The pattern consists of slightly flattened eyes

or angular shape, evenly

located throughout the mass.

Cheeses cut well into thin slices.

Dutch cheese is round in shape,

squared.

Dutch round has a mass fraction

fat in dry matter 50%, moisture - not

more than 43%, salt in mature cheese 2-3%. Cheese

has a spherical shape with a diameter of 13-15 cm and

weight 2-2.5 kg.

Dutch bar has a mass fraction

fat 45% and moisture no more than 44%. Cheese has

the shape of a rectangular block weighing 2.5-6 kg.

Duration of ripening is 2.5 months. Cheddar cheese

has a mass fraction of fat in dry matter of 50%, moisture

- no more than 40%, salt - 1.5-2.5%.

When producing Cheddar, bacterial bacteria are used.

sourdough consisting of lactic acid cultures

streptococci and lactic acid bacilli.

A feature of Cheddar cheese technology: the processed cheese mass is sent to

molding machine, where the cheese layer

pressed, cut into blocks and sent to

cheddarization.

Cheddarization of the cheese mass occurs at

special trolleys at a temperature of 30-32 °C in

for 1.5-2 hours.

Cheddarization is the process of changing the cheese

mass under the influence of lactic acid up to

its achievement of a fibrous-layered structure in

as a result of enhanced lactic acid process.

Cheddar cheese

After cheddarization, the cheese blocks are crushed,mixed with salt, shaped, labeled and

pressed.

Duration of cheese ripening - 3 months,

and the first 1-1.5 months. they ripen at

temperature 10-14 °C; final stage

maturation is carried out at a temperature of 8-10 ° C.

Cheddar cheese is produced in large and

small rectangular blocks weighing 16-22 kg

or 2.5-4 kg.

Taste and smell - cheesy, slightly sour;

The dough is plastic, slightly spreadable and

incoherent;

There is no picture, but presence is allowed

a small amount of voids. Russian cheese – hard rennet with

increased levels of lactic acid

fermentation.

Mass fraction of fat 50%, moisture - no more

43%, salts - 1.3-1.8%.

Feature of the technology - cheese grain after

second heating and partial salting

stand for about 30 minutes. at a temperature of 40

°C, which provides enhanced lactic acid

fermentation.

Salting of cheese is carried out partially or

completely in grain.

The cheese is formed in bulk.

Russian cheese

In form, Russian cheese is produced in the formlow cylinder or rectangular block with

slightly convex side surfaces.

Weight of cylindrical cheese 4.7-11 kg

bar - 5-7.5 kg.

Duration of ripening is 2-2.5 months.

Taste and smell - pronounced cheesy, slightly

sour.

The dough is soft, plastic, homogeneous throughout

weight; Slightly dense dough is allowed.

Pattern - evenly spaced eyes

irregular, angular and slit-shaped

(the formation of the cheese grain occurs

in bulk at reduced pressure

pressing).

Grated cheeses (Gorno-Altai, Caucasian) -

Grated cheeses (Gornoaltaisky,Caucasian) Produce

by technology

Swiss cheese;

They ripen for a long time (180-350

days);

These cheeses have a dense

consistency, well preserved

elevated temperatures;

It is recommended to eat them in

grated form.

Semi-hard rennet cheeses

This group includes fatty cheeses (Latvian, Piquant,Nyamu-us, Novoukrainsky, etc.), as well as cheeses with

low fat content (Kaunas, Klaipeda,

Payuris and others).

The peculiarity of the production of these cheeses is that

that they are produced using hard cheese technology, but

do not use forced pressing

(self-pressing).

Ripened like soft cheeses with the help of enzymes

lactic acid bacteria and microflora enzymes

cheese slime.

Semi-hard cheeses are combined into a separate group and

characteristic spicy, slightly ammoniacal (piquant)

taste and smell.

Mature cheeses are packed in capped foil,

subparchment and other coverings.

Soft rennet cheeses

Soft cheeses as opposed to other rennet cheesescontain a large amount of soluble protein (up to

85%) and vitamins, which gives them even higher

nutritional value.

Soft cheeses have a wide range of flavors

- from pleasant lactic acid to pronounced cheesy

with a slightly ammonia or mushroom flavor

(Dorogobuzhsky, White dessert) or hot pepper

(Roquefort).

All soft cheeses are produced only from

pasteurized milk using pure cultures

bacterial starter cultures, microflora of cheese mucus and

mold.

Technological process for the production of soft cheeses

designed in such a way as to obtain tender cheeses,

soft consistency and specific taste.

Technology Features:

use of mature milk with an acidity of 25 °T,longer milk coagulation than with

production of hard cheeses;

placing large grains of cheese (sometimes the curd is not

crush);

absence of second heating and forced

pressing.

Soft cheeses do not have a rind and the heads of the cheese are not marked.

Cheeses have a high moisture content (50-65%) and salt

(2,5-5%).

Soft cheeses, depending on the method of obtaining the curd,

divided into rennet, rennet-acid and

acidic.

Quality of soft cheeses and their organoleptic characteristics

formed during ripening under the action of enzymes

bacterial cultures.

Based on general organoleptic characteristics and technology, soft cheeses are divided into five species subgroups:

Cheeses ripened with the participation of lactic acid bacteriaand microflora of cheese mucus, which have acute,

piquant, slightly ammonia-like taste and smell;

Cheeses ripened with the participation of lactic acid bacteria

as well as microflora of cheese mucus and white mold,

developing on the surface of the cheese.

Cheeses ripened with the participation of lactic acid bacteria

and white mold developing on the surface of the cheese.

Cheeses ripened with the participation of lactic acid bacteria

and greenish-blue mold developing in the dough

cheeses with a sharp, peppery taste and smell

(Roquefort, Armenian Roquefort, etc.).

Fresh cheeses produced with the participation of

lactic acid bacteria without maturation, having pure

fermented milk taste and smell, with a taste of fillers

(Amateur fresh, Naroch, Gelendzhik, Blade,

Adygei, Homemade, Creamy, etc.).

Camembert cheese

Roquefort cheese

Currently it is obtained from cow's milk when ripeinvolving lactic acid bacteria and greenish-blue mold

Penic. rogueforti developing inside the cheese dough.

Roquefort cheese has a mass fraction of fat in dry matter of 50%, moisture

- no more than 46%, salt - no more than 5%; duration

maturation 2 months

Mold spores are introduced into the milk at the same time as the starter. In 3-5

days After salting, the cheese heads are pierced with needles for quick

and uniform development of mold introduced into the cheese.

Cheeses are ripened in a chamber with a high RHV - 92-95% at 6-8 °C. IN

the cheese ripening room is provided with constant

influx of fresh cold air for better mold growth.

Penic mold. rogueforti, in addition to protein breakdown, secretes lipase,

under the influence of which decomposition products accumulate in cheese

milk fat. The resulting free volatile fatty

acids react with ammonia and form

pepper-flavored substance.

Roquefort cheese has a sharp, salty, peppery taste and a specific

aroma. The consistency is delicate, oily, homogeneous, slightly

tiny. A small density of dough in the outer is allowed

layer. At a distance of 1.5-3.0 cm from the side surface throughout

blue-green mold should be distributed throughout the cheese mass

colors. The cheese is cylindrical in shape, weighing 2.0-3.5 kg.

Roquefort cheese

Adyghe cheese

It is the national dairy product of the Adyghe people.It is produced in two types: fresh and smoked.

Adyghe cheese has a mass fraction of fat of 45%, moisture -

no more than 60%, salt - no more than 2.0%.

The cheese is sold at three days of age.

The cheese is shaped like a low cylinder weighing 1.0-1.5 kg.

If the cheese is produced using traditional technology, then

its surface is wrinkled, with traces of twigs, so

how self-pressing occurs in wicker wicker

baskets.

The surface of the cheese can be smooth. Crust without thick

subcortical layer, with the presence of yellow spots on

surface of the cheese.

The taste and smell are clean, spicy, slightly sour, with

pronounced taste and smell of pasteurization.

The consistency is moderately dense and delicate.

Adyghe cheese

Brine cheeses (brynza, table cheese, Chanakh, Suluguni, Georgian, Ossetian, Tushinsky, Lori)

Brine cheeses are combined into one group according toorganoleptic characteristics, technology and chemical

composition.

Brine cheeses are produced both from pasteurized,

and from raw milk with the addition of bacterial

sourdough

A characteristic feature of brine cheeses is

high content of table salt (4-7%),

increased amount of moisture (47-53%).

Cheese mass for the production of brine cheeses

self-presses and slightly presses, ripening

and storage takes place in 18-20% brine

concentration.

Brine cheeses do not have a rind and have a sharp

salty taste and sour milk taste.

Cheeses, except feta cheese, have eyes of various shapes.

The consistency is homogeneous, dense, slightly brittle (at

Suluguni - layered).

Fermented milk cheeses

In the production of fermented milk cheeses, milkcoagulates with lactic acid.

The resulting cheese mass has a high

acidity, and is involved in the ripening of cheeses

almost just lactic acid.

Mainly produced fresh

fermented milk cheeses such as cottage cheese and products,

prepared from it.

Fermented milk cheeses, like rennet cheeses, can be

divided into hard and soft.

From hard fermented milk cheeses essentially

Only one cheese is produced - Green.

Maturation of cheese mass in hard cheeses

occurs under anaerobic conditions.

Processed cheeses

Depending on the type of main raw material,technology and chemical composition,

organoleptic characteristics of processed cheeses

are divided into species groups:

processed slice cheeses;

processed sausage cheeses;

processed cheeses

pasty;

sweet processed cheeses;

canned processed cheeses;

processed cheeses for lunch.

The raw materials for the production of processed cheese are:

natural mature cheeses;low-fat semi-finished cheese;

quick-ripening cheese intended for

melting;

fat and low-fat cottage cheese;

feta cheese and other pickled cheeses;

dry and condensed milk;

butter and plastic cream;

buttermilk and whey.

In addition, various spices and spices, paste are used

krill "Ocean" and other food fillers and

aromatic additives.

Melting salts are used to melt the mixture.

Features of the technology

Preparation of raw materials (from paraffin cheesesparaffin is removed, rindless cheeses are cleaned

and wash);

grinding on grinders until obtaining

homogeneous mass with particle size 0.3-0.5

mm;

preparing the mixture and holding the mass for

maturation from 30 minutes to 3 hours;

melting in special boilers at

temperature 80-85 °C;

homogenization of the mixture (for pasty

cheeses);

hot packing on automatic machines

portions of various weights and shapes.

Process flow diagram for the production of processed cheese

Equipment for the production of processed cheese

Cheese quality control

From each controlled unit of cheese packagingsamples are taken with a cheese probe to determine

organoleptic and physicochemical indicators.

Samples for physical and chemical analyzes are ground and

an average sample weighing about 50 g is isolated.

Hard rennet cheeses are valued at

organoleptic indicators on a 100-point scale

system.

Depending on the amount of points scored, the

type of cheese.

Hard rennet cheeses are not divided into varieties

Russian, Poshekhonsky, Piquant, reduced cheeses

fat content and accelerated ripening (1 month), as well as

soft, melted.

Their quality is determined by the compliance of indicators,

given in the standard or technical specifications. The 100-point score includes the following indicators:

taste and smell - 45 points,

consistency - 25,

drawing - 10,

dough color - 5,

appearance - 10,

packaging and labeling - 5 points.

Cheeses that have a common

score less than 75 points, including

taste and smell less than 34 points, with pronounced

fodder, sour, musty, bitter, rancid,

putrid, with foreign tastes and odors

petroleum products.

If the quality of the cheese does not meet the requirements

current normative and technical documentation when re-testing cheese

sent for industrial processing.

Marking

For cheeses of different fat content, differentshapes and sizes of the brand, their quantity and order

locations:

cheeses of 50% fat content of the Swiss group,

Dutch, Cheddar and Russian - in the shape of a square

with sides 60 or 23 mm depending on weight

cheese;

cheeses 55% fat - in the shape of a circle with a diameter of 50

or 30 mm;

cheeses with 45% fat content - in regular form

octagon;

cheeses 40% fat (for melting) - in the form

equilateral triangle with side 40 mm;

cheeses with 30% fat content have a production grade of

shape of a regular hexagon;

cheeses 20% fat - in isosceles shape

trapezoids.

Allowed to be applied to areas free of markings.

surface using a stamp with the name of the cheese. Each wheel of cheese should have

the date of manufacture is indicated (at the top is the date

output, month below).

On cheese exported

press the third digit on the right,

indicating the cheese cooking number.

Soft and pickled cheeses are not labeled.

The production date is indicated on the cards. When assessing the appearance of cheese, pay attention to

the shape of the cheese, the condition of its surface, coating and

crusts.

By the shape of the cheese you can determine what type it is.

refers to cheese, indirectly determine its quality.

When examining the appearance of the cheese, its color and

drawing of cheese dough.

The sample of cheese taken with a probe is cut lengthwise and

inspected for color. At the same time, pay attention to

uniformity and uniformity of color throughout the mass

cheese.

The pattern of the cheese is assessed based on the selected cylinder

cheese, paying attention to the shape, quantity,

the size and location of the eyes on the cut of the cheese. At

a strongly spongy or ragged pattern in the cheese

implementation is not allowed. The consistency of the cheese is assessed by

the totality of its properties: degree of density,

hardness, uniformity and feel,

arising from the excitation of mechanical and

tactile receptors in the oral cavity.

An elongated column of cheese, when slightly bent, does not

should break or crumble.

The density and hardness of the cheese dough is determined by

grating a piece of cheese or

instrumental method.

Cheeses with coarse,

hard, rubbery, prickly consistency. Taste, smell and aroma are the main

indicator by which to determine

quality and compliance of the cheese with this

mind.

To determine the taste of cheese, take dough

central part.

The aroma of the cheese is assessed immediately after

using a probe to remove a column of cheese from

heads.

High quality cheese should not

have off-flavors and

smells. The quality of processed cheeses is assessed using a 30-point system:

Taste and smell - 15 points

Consistency - 9 points

Dough color - 2 points

Appearance - 2 points

Packaging and labeling - 2 points

Sum of organoleptic scores

indicators must be at least 19 points,

including taste and smell - 10,

consistency - 6, color - 1, appearance

- 1 and packaging and markings - 1.

Processed cheeses that received a score

less than 19 points are not allowed for sale,

and are recyclable.

Defects of cheeses and the reasons for their occurrence

Defects arise when using raw materialslow quality, violation of technology,

storage and transportation conditions.

The most common defects in

practice, can be divided into four

groups:

appearance defects,

defects of taste and smell,

defects of consistency,

defects in drawings.

Defects in appearance

Warmed rind of rennet cheese;Subcortical mold;

Deformed cheese.

Defects of taste and smell

Sour taste;

Bitter taste;

Rancid taste;

Greasy taste;

Feed taste and smell;

Musty taste and smell;

Ammonia taste and smell;

Alkaline taste and smell of processed cheese.

Defects of structure and consistency

Solidconsistency of rennet cheese;

Rubbery consistency of rennet cheese;

The prickly structure of rennet cheese;

Crumbly structure of rennet cheese;

Unbound structure of rennet cheese;

Mealy consistency of processed cheese;

Loose structure and consistency

processed cheese;

Sticky consistency of processed cheese;

Drawing defects

Voidrennet cheese pattern;

Torn pattern of rennet cheese;

Uneven pattern of rennet cheese;

Reticulate pattern of rennet cheese;

Lack of drawing.

Biotechnological cheese production.

- Completed

- 2nd year student, 4th group

- Faculty of Natural Sciences

- Krasnikov M.V.

- 1. What is cheese?

- 2. The main stages of cheese production technology.

- Preparing milk

- Milk curdling

- Processing of rennet curd

- Molding and pressing of cheese mass

- Salting cheeses

- Maturing of cheeses

- Filling, labeling, packaging and transportation

- Cheese storage

- In general, the process of producing rennet cheeses can be represented by the following diagram:

- preparing milk for processing;

- milk curdling;

- curd and curd processing;

- molding and pressing cheese;

- salting cheese;

- cheese ripening;

- preparing cheese for sale (packaging, labeling, packaging and transportation);

- storage.

- The purpose of preparation is to ensure the composition and properties of milk necessary for cheese production.

- Preparing milk for coagulation includes the following technological operations: reserving and maturing milk, its normalization, pasteurization of normalized milk, cooling to coagulation temperature, adding bacterial starter, calcium chloride and rennet.

- Devices designed for reserving and maturing milk, its normalization and pasteurization.

- Milk coagulation is the main method for isolating milk protein in cheese making; usually casein is released into the curd, the remaining proteins go into whey, which is why they are usually called whey.

- Milk curdling may be rennet And acidic.

- A device in which milk coagulates under the influence of steam.

- The purpose of curd processing is to create conditions for the microbiological and enzymatic processes necessary for cheese production. This is achieved by partial dehydration of the clot.

- The degree of readiness of the clot is determined by its density.

- Apparatus for clot processing.

- Molding of the cheese mass is a set of technological operations aimed at separating the cheese grain from the whey located between the grains and forming a monolith (layer) from it, and then individual cheese heads or blocks with the required shape, size and weight.

- Three main molding methods are used: from layer, in bulk, in bulk.

- Cheese molding machine.

- The cheese is salted to give it the appropriate taste. Salting also affects the structure, consistency and quality of the product. At the same time, salt regulates microbiological and biochemical processes in cheese.

- Container, rack for salting cheese

- Cheese salting system.

- Cheese after pressing and salting is a rubbery mass without taste or distinct pattern. It acquires the chemical composition and organoleptic characteristics characteristic of this cheese only as a result of profound biochemical and physical changes in its components during the ripening process.

- Laser marking of cheese.

- Packing.

- Marking.

- Package.

- Transportation.

- Cheeses are stored on racks or packed in containers stacked on slats or pallets.

- Thank you for your attention

1 of 24

Presentation - Cheeses

Text of this presentation

CHEESE

OP.02. Physiology of nutrition with the basics of food merchandising

Shubina E.A.

Cheese production

To make cheeses, rennet is added to pasteurized and cooled milk and left to form a curd. The resulting curd is cut into cubes - small (for hard cheeses) and large (for soft cheeses). The whey is drained, the cheese grains are heated (second heating) to better separate the whey, then the cheese grains are shaped and pressed. When molding cheeses, they are marked by pressing casein numbers into the cheese dough, which indicate the number (numerator) and month of production (denominator), and the brewing number. To add flavor to the cheese, it is salted by rubbing the cheese heads with dry salt or immersing them in a saline solution, and sent to cold cellars for ripening. When ripened, cheeses acquire a characteristic taste, aroma, texture and pattern, due to the breakdown of proteins under the action of rennet enzymes, lactic acid bacteria and the formation of simpler easily digestible substances (amino acids, ammonia, aromatic substances) and carbon dioxide, which permeates the entire dense mass of cheese, forming eyes .

Shubina E.A.

Cheese production

To protect the cheese rind from destruction and mold formation, cheeses are paraffinized, and some are covered with a polymer film such as saran. A production mark is applied to the surface of the cheeses: for cheeses with 50% fat content - a square, for 45% fat content - a regular octagon, for 30% fat content - a hexagon. Film-coated cheeses do not have a rind, so the amount of the edible part of the cheese increases by 6...7%; The drying out of cheese during ripening and storage is also reduced.

Shubina E.A.

Cheese production

According to the method of milk coagulation, cheeses can be rennet, which is produced by coagulating milk protein with milk-clotting rennet enzyme, or fermented milk cheese, in which milk proteins are coagulated by lactic acid bacteria. Based on consistency, moisture content, and production technology, cheeses are divided into hard, soft, and brined. Processed cheeses are included in a separate group. In terms of fat content in dry matter, cheeses are produced with 45 and 50% fat content, less often with 20 and 30% fat content.

Shubina E.A.

Hard rennet cheesesCheeses pressed with a high second heating temperature (more than 50 °C)

“Swiss”, “Altai”, “Soviet”. Cheeses contain fat in dry matter of at least 50%, moisture not more than 42%, salt 1.5...2.5%. “Swiss” cheese has the shape of a low cylinder and is produced for sale at an age of at least 180 days. "Altai" cheese has the shape of a low cylinder, at least 120 days. “Soviet” cheese has the shape of a rectangular block, at least 120 days. These cheeses have a strong rind, without damage and a thick subcrustal layer, coated with paraffin, polymer or combined compounds; serpyanka prints are allowed on the surface; “Swiss” cheese has a dry coating of grayish-white color. The taste and smell are clean, pronounced cheesy, slightly sweet, for “Altai”, “Soviet” cheeses - slightly spicy. The dough is plastic, homogeneous throughout the entire mass. Color from white to slightly yellow. When cut, the cheeses have a pattern consisting of round or oval-shaped eyes, evenly distributed throughout the mass. Cheeses from this group are recommended for breakfast and lunch. Imported cheeses included in this group include Emmental, Gruyère, Beaufort, Alpine and others.

Shubina E.A.

Soviet

Swiss

Emmental

Beaufort

Beaufort

Shubina E.A.

Cheeses pressed with a low temperature of the second heating (36...42 0C)

“Dutch”, “Yaroslavl”, “Estonian”, “Poshekhonsky”, “Uglich”, “Kostroma”, “Stepnoy”. Cheeses of this group contain 45% fat in dry matter, except for “Dutch” with 50% fat, 44% moisture, and 1.5...3% salt. “Dutch” round cheese has a spherical shape, “Dutch block” cheese has a rectangular block, produced for sale at the age of 60 days. The taste and smell are moderately cheesy, sour, with some pungency in “Gollandsky”, “Stepnoy”, and in “Estonsky” - light spice. The dough is homogeneous throughout the entire mass, plastic, in “Kostromsky”, “Yaroslavsky”, “Uglichsky” it is slightly brittle at the bend. The color is from white to slightly yellow, uniform throughout the entire mass. The cut pattern consists of round, oval or angular eyes. This group includes semi-hard cheeses with low fat content - “Litovsky”, which has the shape of a rectangular block, “Pribaltiysky”, “Vyrusky” - a low cylinder. These cheeses contain 30% fat in dry matter, moisture 52...55%, salt 1.5...3%. Taste and smell - mild cheese, fermented milk; Slight bitterness and slightly fodder flavor are allowed. The consistency is dense, slightly brittle at the bend of the Litovskiy and Võruskiy cheeses. No drawing is allowed. Among the imported cheeses, this group includes the cheeses “Gouda”, “Edam”, etc. Cheeses from this group are recommended as a seasoning for vegetable dishes and for breakfast.

Shubina E.A.

Poshekhonsky

Poshekhonsky

Gouda

Dutch

Shubina E.A.

Self-pressing cheeses, with a low second heating temperature, ripening with the participation of cheese mucus microflora

This group includes cheeses “Latvian”, which have the shape of a block with a square base, and “Pikantny” - a rectangular block. “Latvian” cheese contains 45% fat in dry matter, 48% moisture, 2...2.5% salt, “Pikantny” cheese contains 55% fat, 44% moisture, 2...2.5% salt. The taste and smell are distinctly cheesy, slightly ammoniacal; for “Spicy” the presence of slight bitterness and a fodder taste is allowed. Color ranges from white to faint yellow. The dough is soft and plastic. The eyes are irregular, angular, slit-shaped, evenly spaced. Among imported cheeses, this group includes Tilsit and Brik cheeses. These cheeses are recommended for coffee, cocoa, and tea.

Shubina E.A.

Tilsit

Brick

Spicy

Shubina E.A.

Cheeses pressed with a low second heating temperature and a high level of lactic fermentation

The cheeses of this group differ from the previous groups of cheeses in that the cheese grains undergo ripening (cheddarization) before molding for several hours at a temperature of 33... 35 ° C. The cheese mass becomes soft and separates. This group includes “Cheddar” and “Russian” cheeses. Cheddar cheese contains 50% fat in dry matter, 42% moisture, 1.5...2% salt. The film adheres tightly to the cheese, the surface is clean. The taste and smell are cheesy, sour, light spice is allowed. The dough is plastic, homogeneous, slightly incoherent is allowed. Color ranges from white to faint yellow. There is no drawing, a small amount of voids is allowed. Rossiyskiy cheese is produced in the form of a low cylinder or a rectangular block. Cheese contains 50% fat in dry matter, 43% moisture, 1.3...1.8% salt. When producing this cheese, the mass is not completely cheddarized. The taste and smell are distinctly cheesy, slightly sour. The dough is soft, plastic, slightly dense. Color from light yellow to yellow. The section has a uniformly spaced pattern consisting of irregular, angular, slit-shaped eyes. These cheeses are used for sandwiches and served for breakfast.

Shubina E.A.

Russian

Cheddar

Shubina E.A.

Soft rennet cheeses

This group of cheeses differs from hard cheeses in their higher moisture content (46...60%) and more delicate consistency. When they ripen, molds and mucus-forming bacteria take part. These cheeses are produced without second heating, by self-pressing. Cheeses that ripen with the participation of cheese mucus microflora on the surface This group includes Smolensky cheese. The taste is pungent, slightly ammoniacal. The consistency is delicate, slightly spreadable, oily. The dough is smooth, without eyes or with small irregularly shaped eyes. The color of the dough is from white to slightly yellow.

Shubina E.A.

Smolensky

Cheeses ripened with the participation of mold cultures growing in the dough

Roquefort cheese belongs to this group. Taste and smell - hot, salty, peppery. The dough is tender, buttery, slightly crumbly. When cut, blue-green mold should be distributed throughout the entire mass of cheese. The color of the dough is from white to slightly yellow.

Roquefort

Shubina E.A.

Cheeses ripened with pure cultures of surface white mold

This group includes Russian Camembert cheese. The cheese has a delicate, uniform consistency; there is white mold on the surface. The cheese has a pure sour-milk taste with a slightly mushroom flavor and slight bitterness; color from white to light yellow. Soft rennet cheeses stimulate the appetite and can be eaten before lunch or for breakfast. This group of imported cheeses includes Brie, Gorgonzola, Stilton and others.

Shubina E.A.

Camembert

Gorgonzola

Bree

Shubina E.A.

Brine cheeses

They do not have a crust; they mature in brine. The salt content in them reaches from 3 to 8%, fat - 45%, water - 50... 55%. These cheeses are made from sheep, goat, cow's milk or a mixture of them. Brine cheeses include “Kobisky”, “Osetinsky”, “Gruzinsky”, “Stolovy”, “Imeretinsky”, “Karachaevsky” cheeses, and feta cheese. These cheeses are produced without cheddaring or melting the cheese mass. Brine cheeses with cheddarization and melting of the cheese mass include “Suluguni” and “Layered” cheeses. The technology of these cheeses does not include pressing or ripening operations; Cheese sales period is 25 days. The cheeses have a moderately salty, clean, sour-milk taste. The dough is dense, slightly brittle, for feta cheese it is moderately dense, tender, and not crumbly, for Suluguni it is dense, layered, and elastic. A pattern on the section in the form of eyes of various shapes and sizes; In feta cheese and Suluguni cheese, voids of irregular shape are allowed. These cheeses are used as a snack. Among the imported cheeses, this group includes the cheeses “Feta”, “Domiati”, “Mozzarella”, etc.

Shubina E.A.

Brynza

Suluguni

Mozzarella

Ossetian

Shubina E.A.

Fermented milk cheeses

These include “Green” cheese, which is made from skim milk fermented with a starter of lactic acid bacteria. The curd (ciger) is separated from the whey, after ripening, salt and ground leaves of the sweet clover herb are added, due to which the cheese has a greenish color. A head of cheese in the form of a truncated cone weighing 100...200 g. The cheese has a dense consistency, a rough surface, and does not have a pattern at the break. The taste is sharply salted with the smell of sweet clover. The cheese contains 40% moisture, 6.5% salt, 2.5% sweet clover. Packed in foil with a parchment lining. Green cheese is also produced in the form of powder in bags.

Cheese "Green"

Shubina E.A.

Processed cheeses

Processed cheeses are produced from various types of natural cheeses, cottage cheese, sour cream, milk powder, butter, with or without spices, by heat treatment with the addition of melting salts (sodium phosphate and sodium citrate). Our country produces more than 40 types of processed cheeses: “Yantar”, “Druzhba”, “Leto”, “Chocolate”, “Nut”, “Cherry”, sausage “Caucasian” and “Okhotnichiy”, “Coffee”, “Kostromskoy” , “Cheese with mushrooms for soup”, “Cheese with onions for soup”, etc. The fat content in them is 30, 40, 45, 50 and 60% (on a dry basis). Processed cheeses have a color from slightly yellow to yellow, uniform throughout the entire mass, while cheeses with spices have the inclusion of spices; pronounced taste and smell of the cheese from which they are made, or the taste of added additives; The consistency is homogeneous, tender, dense, and in some cases slightly spreadable. In cooking, cheeses are widely used as cold appetizers, for sandwiches, when baking many dishes, and boiled pasta is sprinkled with grated hard cheese.

Shubina E.A.

Shubina E.A.

Cheese quality requirements

Depending on quality, hard rennet cheeses are divided into premium and 1st grade. Cheeses “Russian”, “Poshekhonsky”, “Pikantny”, low-fat cheeses, soft rennet, brine and processed cheeses are not divided into varieties (GOST 7616 - 85). The grade of cheese is determined organoleptically according to a 100-point system, in which each indicator is given a certain number of points: taste, smell - 45, consistency - 25, pattern - 10, dough color - 5, appearance - 10, packaging, labeling - 5 points. Depending on the amount of points, cheeses are assigned to a certain grade: highest - with a total score of 100...87 points, including 37 points for taste and smell; to the 1st - with a total score of 86... 75 points, including at least 34 points for taste and smell. Cheese defects include weak taste and aroma, bitter taste, food taste; crumbly, loose consistency, lack of pattern; cracks in the rind, etc. Cheeses with foreign impurities in the dough, those that have lost their shape, affected by subcortical mold, etc. are not allowed to be accepted. The content of residual amounts of pesticides, heavy metals and arsenic must not exceed the approved standards. Coli bacteria are not allowed.

Shubina E.A.

Cheese storage

Hard cheeses are stored at a temperature of (4 ± 2) °C and a relative air humidity of 85...87% - 15 days, processed cheeses - 10, soft, pickled, "Russian Camembert" - 5 days.

Shubina E.A.

Sources of information

https://yandex.ru/images - pictures by Z.P. Matyukhin “Commodity research of food products”. M.: publishing house "Academy", 2013

Shubina E.A.

Code for embedding a presentation video player on your website:

The initial influence on the taste is exerted by lactic acid, which is formed as a result of microfermentation. As the cheese ripens, the taste of the cheese is influenced by protein substances: peptides, amino acids and other products of higher breakdown (amine nitrogen, ammonia nitrogen, etc.). Volatile fatty acids and carbonyl compounds (aldehydes, ketones), formed during the breakdown of milk sugar, amino acids and partly fat, play a major role in the formation of the taste of cheeses. The consistency of newly formed cheese is rough and rubbery, over time under the influence of the resulting lactic acid and salting of the cheese. The proteins swell and the consistency of the cheese becomes more elastic. With more mature cheese, the dough becomes somewhat brittle. When cheeses ripen, as a result of biochemical reactions, gases are released (CO2, H2, ammonia, O2, N, etc.). In cheeses with high t.v. The formation of the pattern is caused by propionic acid bacteria that ferment milk sugar, lactic acid and lactates. In the production of cheeses with low temperature v.n. flavor-forming bacteria ferment milk sugar with the accumulation of lactic acid, acetaldehyde, CO2, H2. Butyric acid bacteria cause rapid gas formation and swelling of cheeses with the formation of a spongy or ragged pattern.

Submitting your good work to the knowledge base is easy. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

MINISTRY OF EDUCATION AND SCIENCE

REPUBLIC OF TATARSTAN

NABEREZHNOCHELNY STATE

TRADE AND TECHNOLOGY INSTITUTE

WRITTEN EXAMINATION PAPER

Topic: “Organization of the sale of hard cheeses

in the store “Borovetskoye No. 1”

Plan

1. History of cheese

2. Organization of sale of hard cheeses

2.1. Product history

2.2. Characteristics of the assortment

2.3. Quality requirements

2.4. Packaging and labeling

2.5. Acceptance by quantity and quality

2.6. Storage

2.7. Preparation for sale

2.8. Placement and display

2.9. Sales and consultation

Conclusions and suggestions

List of used literature

1. History of cheese

Cheese making was known in ancient times, but only from the second half of the 19th century. It begins to gradually transform from fishing into industrial production.

In Russia, the first cheese-making plant was organized in 1795 on the estate of Prince Meshchersky in the village of Lotoshino, Tver province. In subsequent years, factories also appeared in other landowners' farms, where Swiss cheesemakers were invited. They bought milk from the landowner and processed it themselves into Swiss cheese. During this period, Russian terms for cheese making appeared, often they did not correspond to one or another technological process: for example, “cooking cheese”, “fermentation of milk”, “rennet starter”. The term “cooking” arose when observing the production of Swiss cheese, which was carried out in fire-heated boilers.

Production conditions in Russia and Switzerland were different, and the mechanical transfer of Swiss cheese technology without taking into account the composition and properties of milk, climate and geographical conditions could not give good results. Therefore, the cheese was not of high quality.

In the 19th century Swiss cheese making penetrates into the Transcaucasus, where it has found fertile soil due to the similarity of the natural historical conditions of Transcaucasia and Switzerland. The scale of production of Emmental (Swiss) cheese in the Caucasus has expanded. Changes also occurred in cheese production technology - they began to use water and steam heating of cheese boilers, and more advanced processing tools appeared - metal harps, whorls. However, the total volume of production remained small, and until the 60s of the XIX century. the production of Swiss and other types of cheese did not extend beyond the boundaries of the landowners' estates, where the craftsmen continued to be predominantly the Swiss, who kept the technology secret.

By 1866, there were only 72 landowner cheese factories in the European part of Russia. From 1866 to 1890, cheese making developed rapidly, and cheese production increased more than 10 times during this period. In the 70s, production of Dutch cheese began in Russia.

In the last decades of the 19th century. The handicraft cheese-making industry was reorganized, developing on the basis of rapidly capitalizing small peasant farming. A significant role in the development of domestic cheese making belongs to the famous founder of artel cheese dairies V.I. Blandov, as well as N.V. Vereshchagin, who actively participated in the organization of artel cheese-making factories. He created the first artel cheese factory in 1866 in Otrokovichi, Tver province.

In 1871, Vereshchagin organized in the village. Edimonovo, Tver province, is the first dairy farming school in Russia, which was the main center for training masters of cheese and butter making. In 1883, the first dairy laboratory in Russia was created at the school. This marked the beginning of scientific research in the field of biochemistry and technology of milk and dairy products in our country. The organizer of this laboratory was Prof. A.A. Kalantar. He has carried out extensive research on the chemistry and technology of milk, in particular on the use of calcium salts in the production of Swiss cheese,

The founder of the Russian school of cheese making is prof. S.V.Parashchuk. He carried out significant work on studying the influence of feed on the composition and properties of milk, the properties of rennet and pepsin.

Before the First World War in 1914, there were about 2,000 cheese-making enterprises in Russia, producing about 7,000 tons of cheese per year. The main regions of cheese production in Russia were: central regions (Yaroslavl, Tver, Smolensk, Kostroma), North Caucasus (Rostov region, Stavropol region), Transcaucasia (Georgia and Armenia), Western Siberia (Altai region and Novosibirsk region), Baltic states (Lithuania , Latvia, Estonia).

The assortment was limited, mainly cheeses were produced: Dutch round, backstein, tilsit, Swiss, Tushino, a small amount of green cheese, soft cheeses - brie, Neuchâtel, Camembert, Limburg. Soft cheeses were produced mainly in the north-west of Russia, green cheeses were produced in the Upper Volga region and on the Oka River.

After the October Revolution, cheese-making enterprises became state property. In the period from 1917 to 1931, technical re-equipment of industry took place. New steam-mechanized plants are being built, and technically advanced equipment for that time is being installed. New construction is being carried out in old, established and newly created cheese-making areas. During this period, a mechanized cheese-making industry was organized in Altai. The production of Swiss-type cheeses is widely developing in the Transcaucasus - Georgia and Armenia.

1931--1941 are characterized by a sharp increase in cheese production on the raw material base of dairy farms on collective and state farms. Significant funds are being invested in the construction of new large factories and inter-district cheese storage facilities.

During the same period, as a result of the work of Soviet scientists and production workers, the range of cheeses produced by the domestic industry significantly expanded. Soviet, Moscow, Yaroslavl, Uglich, Volzhsky, etc. cheeses appeared. The production of processed cheeses began to develop, which was organized in 1934, first at the Moscow, and then at the Leningrad and Rostov processed cheese factories.

Since the main production processes were patented abroad, a series of scientific developments were carried out in our country, laying the foundation for the theory and practice of processed cheese production. They were completed in the 30s by A.P. Sadokova, Sh.G. Gonashvili, N.I. Egorov and A.F. Voitkevich.

The theoretical foundations of processed cheese technology were further developed in the works of S.M. Barkan, who put forward an original theory of cheese melting and studied some of the rheological properties of processed cheeses. A great contribution to the practice of producing processed cheeses was made by M.F. Kuleshova, who developed a number of technologies for the main range of processed cheeses.

The increased consumer demand for cheese, which was the result of growing material well-being, required further development of the cheese-making industry, which was provided for by the corresponding plans. The Great Patriotic War and the temporary occupation of a number of regions caused enormous damage to Soviet cheese making.

The pre-war level of production was reached only by the end of the 40s. The construction of new large cheese-making factories, such as Tikhoretsky and Leningradsky in the Krasnodar Territory, and the reconstruction of existing enterprises made it possible to increase cheese production in 1960 compared to 1950 by more than 3 times. New large cheese-making factories and cheese depots are being built in the Baltic states, Belarus, and the Volgograd region. Newly built factories are equipped with imported equipment and high-performance lines. The technology of new types of cheeses is being developed, such as Russian, piquant, etc. We are organizing the production of cheddar cheese, Swiss block cheese and small accelerated ripening cheeses, such as Susaninsky. The production of Bukovinian cheese has been organized in Ukraine. At the end of the 60s, the production of rindless cheeses and the ripening of cheeses in protective polymer films and coatings began to be widely introduced.

In 1939, the All-Union Research Institute of the Dairy Industry was organized in Moscow, from which the All-Union Research Laboratory of Cheese Making emerged, which was later transformed into the All-Union Research Institute of Butter and Cheese Making Industry, located in Uglich (Yaroslavl region) . Scientists of this institute and its branches in Altai, Lithuania, Stavropol region are responsible for the development of many new types of cheeses that are in great demand among the population, such as Russian, Võru, piquant, athlete, etc.

Much work on many pressing problems of cheese making, along with training personnel for industry, has been carried out by the departments of the Moscow Technological Institute of Meat and Dairy Industry (now the Moscow Institute of Applied Biotechnology), Vologda Dairy Institute, Leningrad Institute of Refrigeration Industry, etc.

Much credit for the development of domestic cheese making and scientific research in this area belongs to A.N. Korolev, D.A. Granikov, Z.X. Dilanyan, A.I. Chebotarev.

2 . Organization of sale of hard cheeses

2.1 Product history

Cheese is the most versatile product of the entire range of dairy products, because... It is ideal for preparing sandwiches, sauces, hot and cold dishes. The chemical composition of cheese includes complete proteins (about 25%), which are easily absorbed by the body, milk fat (about 30%), minerals (calcium, sodium, phosphorus salts, etc.), fat- and water-soluble vitamins (A, D, E, B?, B 2, PP). Cheeses have a high calorie content and physiological value. Its nutritional value, easy digestibility and pleasant taste make it possible to consume cheese not only as an excellent food for healthy and sick people, but also as a snack that stimulates the appetite before meals. Cheese is made from cow, goat, sheep and buffalo milk by curdling and processing. During the production process, it retains all the essential nutrients of milk, with the exception of carbohydrates. During cheese making, a significant portion of the water is removed from milk, resulting in a concentrated food product.

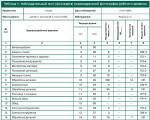

Our country produces a wide range of cheeses. They differ from each other in terms of preparation technology, external characteristics and organoleptic characteristics. Based on the method of milk coagulation, cheeses are divided into rennet (when making cheese, proteins are coagulated under the action of rennet) and fermented milk (when making cheese, proteins are coagulated under the influence of lactic acid). Depending on the characteristics of production, rennet cheeses are divided into hard, soft, brine, processed, and according to the fat content in dry matter - into cheeses with 20, 30, 45, 50% fat content. In the process of cheese production, the decisive factors are the physical properties, chemical composition, and microbiological parameters of milk. Various technological production schemes make it possible to obtain cheeses that differ in chemical composition and organoleptic characteristics. The main processes of cheese production consist of the following operations: milk receiving and sorting, milk coagulation, curd processing, cheese salting, cheese ripening and cheese finishing. Table 11 shows the classification of cheeses in the main range.

2.2 Characteristics of the assortment

In our country, hard rennet cheeses make up the majority of cheeses produced. Based on size and weight, they are divided into large and small. According to production technology and characteristic taste and smell - into the following types: Cheeses of the Swiss type, Dutch type, Cheddar type, Russian type, Latvian type. To produce them, milk normalized for fat content is pasteurized, cooled to a temperature of 33 ° C, and tinted with yellow vegetable paint. Then lactic bacteria starters and rennet powder are added, resulting in the formation of a strong curd. The resulting curd is cut into cubes of cheese grains of various sizes, which, when stirred, stick together and release whey. To separate more whey, the cheese grains are reheated to a temperature of 55-58 °C (high heating for Swiss type cheeses) and 40-45 °C (low heating for Dutch type cheeses). With higher temperatures, more whey is separated. The curd grains are then placed into molds in which excess whey is removed by pressing or self-pressing. The resulting cheese is salted for 5-8 days in a cold basement for ripening at a temperature of 10-15 ° C and a relative humidity of 90-95%. During the ripening process in cheese, under the influence of rennet and enzymes of lactic acid bacteria, the complex substances that make up the protein decompose into simpler and more easily digestible substances. The resulting ripened cheese has a characteristic taste and aroma for each type. During the ripening process of cheese, carbon dioxide accumulates, which pushes the cheese grains apart and forms eyes. A pattern appears in the cheese mass. The ripening time of cheeses is from 35 days to 6 months. To protect cheeses from drying out and molding, many cheeses are waxed. When producing rindless cheeses, at the end of production, the heads are wrapped in a polymer film, which, when heated, fits tightly to the surface of the cheese. Such cheeses are ripened and stored in film.

SWISS TYPE CHEESE. To produce these cheeses, milk of high quality is used in terms of organoleptic properties, bacterial contamination and acidity.

SWISS CHEESE matures for 6 months or more. In appearance it is a large, low cylinder weighing 50-100 kg. On the durable and wrinkle-free crust there are prints of the serpyanka fabric with which the cheese was pressed. A durable dry coating of grayish-white color is allowed, the taste is sweetish, pleasant, with a well-defined taste and aroma. Eyes round or oval, fat content 50%.

SOVIET CHEESE is made from pasteurized milk. It has the shape of a rectangular bar with slightly cut vertical edges and convex side surfaces. Weight - up to 16 kg. The ripening period is 4 months, but the best taste is when ripened for 6-8 months. The taste is close to Swiss. Fat content 50%.

MOSCOW CHEESE is a variety of Soviet cheese, differing in shape - a tall cylinder weighing 6-8 kg. The taste is sweetish and sour, fat content is 50%. CARPATHIAN CHEESE has the shape of a low cylinder. Weight up to 15 kg. Ripens within 2 months. The taste is sweetish and sour.

KUBAN CHEESE represents cheeses of a unified cylindrical shape. In taste, aroma and consistency it is close to Soviet. Weight - up to 10 kg.

DUTCH TYPE CHEESE. Cheeses of this type represent a large assortment of pressed cheeses with a low second heating temperature.

DUTCH CHEESE. When using a low second heating temperature, more whey remains in the cheese mass. This promotes faster development of lactic acid streptococci and faster ripening of cheese (up to 3 months). As a result, small eyes of a round, slightly flattened shape are formed. The consistency of the cheese is elastic, softer than that of Swiss cheese. The shape of the cheese is round, weighing 2-2.5 kg, midget 0.4-0.5 kg; large bar 5-6 kg and small bar 1.5-2.0 kg. Cheese is considered mature when it ripens for 2-2.5 months, Lilliputian for 35 days. When ripening up to 6-8 months, its taste becomes sharper and more pronounced. A sign of good quality can be the appearance of tears in the cheese. Dutch cheese is distinguished by fat content: block cheese - 45%, round cheese - 50%. The taste and aroma are pure, with pungency and sourness, without foreign tastes and odors.

KOSTROMSKY cheese has the shape of a low cylinder with a convex side surface and rounded edges, weighing 9-12 kg (large) and 5-6 kg small. In terms of technology and organoleptic characteristics, it is close to the Dutch one; it ripens in 2.5 months.

YAROSLAVSKY CHEESE is produced in the form of a tall cylinder weighing 2-3 kg, a unified large cylinder weighing 8--10 kg and a unified small cylinder weighing 4--6 kg. In terms of physico-chemical and organoleptic indicators, it is close to the Dutch bar. Fat content 45-50%.

STEPPE cheese is produced in the form of a block with a square base, weighing 5-6 kg. The taste is sharp, the dough is slightly brittle. Fat content -45%. The surface of the bar is waxed.

UGLICH CHEESE has the shape of a rectangular block weighing 2-3 kg. The cheese dough is tender, elastic, slightly brittle with round oval or irregularly shaped eyes. The taste is slightly sour. The cheese matures within 2 months. Fat content - 45%.

POSHEKHONSKY CHEESE has the shape of a low cylinder weighing 5-6 kg. The eyes are round or slightly flattened. Fat content 45%. Duration of ripening is 1.5 months.

ESTONIAN CHEESE. Characterized by accelerated maturation. Can be produced with a ripening period of 30 days. It has the shape of a tall cylinder, weighing 2-3 kg. The taste is slightly sour, a spicy aftertaste is allowed. The dough is soft and plastic. The eyes are round, slightly oval in shape and evenly spaced. Fat content 45%.

DNISTROVSKY CHEESE - quickly ripening. It has the shape of a bar. The dough is soft, slightly spreadable. Fat content 50%.

LITHUANIAN CHEESE. Shape of a rectangular bar, weight 5-6 kg. The taste is delicate sour. Fat content -- 30%.

CHEESE TYPE CHEDDAR. A characteristic feature of the production of cheeses of this group is that before molding the cheese mass is subjected to cheddarization (fermentation). As a result, the development of lactic acid fermentation intensifies and lactic acid accumulates, which, acting on the protein, makes the mass soft, viscous, and stratifies into thin, leaf-like layers. In this case, gas formation occurs, resulting in the formation of irregularly shaped eyes. At the end of ripening before molding, gas formation dies out and the eyes flatten.

CHEDDAR has the shape of a tall cylinder with a steep side surface and flat bases. Its weight is 30-33 kg. Cheese maturity is reached at three months of age. The cheese has a soft shell tightly pressed to the dough. The surface of the cheese is waxed. The taste and smell are slightly sour. The dough is plastic, tender, slightly spreadable. There are no eyes, the fat content is at least 50%. Altai Mountain cheese is a variety of Cheddar cheese.

RUSSIAN TYPE CHEESE. It is made without cheddarization, but after the second heating the cheese grain is kept at a temperature of 41~42 °C for 4-50 minutes, and the acidity increases. Russian cheese is usually salted in grains, followed by adding salt to the head in brine. Sometimes they use complete salting in the grain, without using additional salting in the brine. The cheese has the shape of a low cylinder weighing 11-13 kg (large) and 7-9 kg (small). The taste and smell are slightly sour, pronounced; the dough is soft and plastic; the eyes are irregularly slit-shaped. The cheese has an even thin crust, the surface is covered with paraffin. Ripening period is 70 days. Fat content -- 50%.

LATVIAN TYPE CHEESE - these are semi-hard self-pressing cheeses with a low second heating temperature. The ripening of cheese involves lactic acid and mucus-forming bacteria that develop on the surface. Cheese ripening proceeds from the surface to the center. Cheeses are characterized by a pungent, specific, slightly ammonia-like taste and smell and high moisture content. Latvian cheese has the shape of a bar with a square base and convex side surfaces, weighing 2.2-2.5 kg. The crust is thin, covered with a slightly sticky thin mucus of a red-brown color with light spots. The dough is plastic. The eyes are oval and irregular in shape. Fat content - 45%.

SPICY CHEESE has the shape of a rectangular block weighing 2-4 kg. The consistency is more delicate, as it has a fat content of at least 55%. Ripens in 35-45 days.

Table. Chemical composition and energy value of cheeses (per 100 grams of product)

|

Organic matter |

Minerals |

|||||||||||

|

Kis-you gr. |

||||||||||||

|

Swiss |

||||||||||||

|

Soviet |

||||||||||||

|

Dutch: |

||||||||||||

|

slab |

||||||||||||

|

Kostroma |

||||||||||||

|

Poshekhonsky |

||||||||||||

|

Yaroslavsky |

||||||||||||

|

Russian |

||||||||||||

|

Lithuanian |

||||||||||||

|

Baltic |

||||||||||||

|

Kaunas |

||||||||||||

|

Estonian |

|

Vitamins |

Energy value |

||||||||

|

B carotene |

|||||||||

|

Swiss |

|||||||||

|

Soviet |

|||||||||

|

Dutch: |

|||||||||

|

slab |

|||||||||

|

Kostroma |

|||||||||

|

Poshekhonsky |

|||||||||

|

Yaroslavsky |

|||||||||

|

Russian |

|||||||||

|

Lithuanian |

|||||||||

|

Baltic |

|||||||||

|

Kaunas |

|||||||||

|

Estonian |

3.3 Quality requirements

Hard cheeses (except for Yaroslavl Bolshoi, Kuban Russian, Poshekhonsky, Dnestrovsky, Severny, Pikanny) are divided into highest and first grade, depending on their organoleptic characteristics. The organoleptic method determines the quality of cheeses using a 100-point system. All premium cheeses must have an overall score of 87-100 points. An important indicator is taste and smell - a total score of at least 37 points. The overall score for first grade cheese is 75-86 points, including taste and smell of at least 34 points. Premium cheeses must have the correct shape; the crust is thin, smooth, clean and elastic, without wrinkles. Paraffin cheeses have a whole, undisturbed layer of paraffin. The taste and smell must be pure, characteristic of this species, without foreign tastes and odors. In the first grade, a mild fodder and sour taste is allowed. The consistency of the dough should be elastic and uniform throughout the entire mass. In the first grade, crumbly, loose, hard, belty (with good taste and smell) are allowed. The color of the dough is from white to slightly yellow, uniform throughout the dough. In the first grade, uneven color and uneven distribution of eyes are allowed.

3.4 Packaging and labeling

Cheeses are packaged in wooden boxes and drums with internal partitions. Each package contains cheeses of the same type, variety and approximately the same age. Before packaging, Latvian cheese is wrapped in parchment or sub-parchment; soft cheeses are additionally packaged in aluminum foil. Brine cheeses are placed in barrels and filled with whey brine. Yerevan cheese and feta cheese are placed in tin cans. Processed cheeses are packaged in aluminum foil or containers made of polymer materials, which are placed in boxes or cardboard boxes lined with wrapping paper. In stores, cheeses are placed on racks or left in boxes. Every 5-10 days the cheeses must be turned over and wiped.

A special feature of cheese marking is that production marking is applied to each wheel of cheese and shipping container. On the cheese they indicate: the date of production (day, month), the number of cheese cooking (the numbers are located in the center of the top sheet of the cheese) and the production mark, which has the following symbols: fat content, number of the manufacturer; abbreviated name of the region in which the enterprise is located. These designations allow you to accurately identify each batch of cheese. The marking on the cheese wheel is applied with indelible paint using a stamp, and the production date and brewing number are applied by pressing casein and plastic numbers into the cheese dough or by imprinting metal numbers approved by the Ministry of Health. The shape and size of the production mark are determined depending on the mass fraction of fat in the dry matter of the cheese. For cheeses with a fat content of 50%, the production mark is in the shape of a square, for cheeses with a 45% fat content - in the shape of a regular octagon. The mark is applied to one of the cheese sheets closer to the end part. In addition, it is allowed to stick a label approved in the prescribed manner on the cheese. When packaging cheese in polymer films, the production mark can be applied directly to the films. Also, a colorful label can be applied to the film, which indicates: the name of the cheese, the mass fraction of fat in% in the dry matter of the cheese, the name of the department or enterprise, calorie content, fat and protein content (w/g per 100 g of product). The following information is indicated on the transport packaging; trademark and name of the manufacturer, region index, name of cheese and variety, brewing number and production date; serial number of the place from the beginning of the month; net weight, gross weight of goods, containers and quantity of packaged cheeses; mass fraction of fat in the dry matter of cheese (in%); designation of the standard or specification, price list number of the container; manipulation sign “Afraid of heating.”

3.5 Acceptance by quantity and quality

The main directions for rationalizing the technological process of stores are the widespread introduction of progressive methods of selling goods and serving customers, developing rational technological planning schemes, increasing the level of technical equipment, ensuring an uninterrupted supply of goods, their rational placement and display, and improving the operation of payment units.

Technology for receiving goods in a store

Receiving goods in a store is a vital component of the technological process. It is carried out by financially responsible persons in accordance with instructions on the procedure for accepting production and technical products and consumer goods in terms of quantity and quality.

The rules established by these instructions apply in all cases where a different procedure is not provided for by standards, special delivery conditions, or other mandatory regulatory documents.

Products in the store are accepted according to quantity and quality.

Depending on the method of delivery and packaging of the goods, the acceptance technology is determined.

Acceptance of goods by quantity upon delivery of unpackaged goods, goods in open containers, as well as by gross weight and number of pieces is carried out immediately upon delivery to the store.

If the goods are delivered in a serviceable container, in addition to checking the gross weight and the number of containers, the store has the right to require opening the container and checking the net weight and the number of units in each place.

If the goods are in damaged containers, then the store checks the net weight and number of product units in each location simultaneously with acceptance of the gross weight and number of items at the time of receipt of the goods from the supplier. All technological operations of the store can be conditionally divided into main and auxiliary.

The main ones include operations related to the sale of goods and customer service, selection, measuring, payment for goods, etc.

Auxiliary operations include acceptance of goods by quantity and quality, unpacking, delivery to storerooms, storage, preparation for sale, delivery to the sales floor, placement and display of goods on the sales floor, organization of storage and delivery of containers.

A number of factors influence the store's technological process. The most important of them are the level of development of trade, the volume and structure of goods, the degree of their readiness for sale, sales methods, the state of inventories, the goods supply system, the type and size of a trading enterprise, the degree of its economic independence. Under the influence of these factors, the structure and sequence of technological operations of the store are formed.

In trade practice, three main schemes of technological processes have developed.

First scheme includes the acceptance of goods in terms of quantity and quality, and their delivery immediately to the sales floor for sale. It is the most progressive and is possible only when the goods are delivered in packaged equipment, fully prepared for sale, which eliminates the most labor-intensive operations from the technological process.

By second scheme The technological process includes the acceptance, storage and sale of goods. In this case, there is a need for special storage facilities.

The most complex and less economical is third scheme, in which goods received at the store require preliminary preparation for sale (packing, etc.). With any of the schemes, the entire technological process can be divided into stages.

The first stage is operations with goods before offering them to customers on the sales floor: accepting and preparing them for sale, creating the required storage regime.

The second stage is operations related to direct customer service. This is the most critical section of the technological process. Here, demonstration of products in action, assistance in selection, qualified advice, etc. should be provided at a high level. The peculiarity of this stage is that when performing operations, store workers must not only have professional skills in dealing with people, but also have a good understanding of the psychology of the buyer.

The most important principles of organizing the in-store technological process are:

An integrated approach to determining a rational technological process diagram for a specific store;

Compliance of the store operating technology with the modern scientific and technical level of trade development, achievements of domestic and foreign experience;

Economic efficiency of the adopted technological scheme of the store, ensuring the rational use of material, labor and financial resources.

Creating conditions for the complete safety of goods and their use value;

Reducing the use of manual labor and increasing the efficiency of using commercial and technological equipment.

The introduction of progressive methods of delivery and sale of goods imposes special requirements on the design of store entrances and exits, unloading areas, landing stages, and the strength of floor coverings.

3.6 Storage